|

Northern Mine Research Society Registered Charity 326704 |

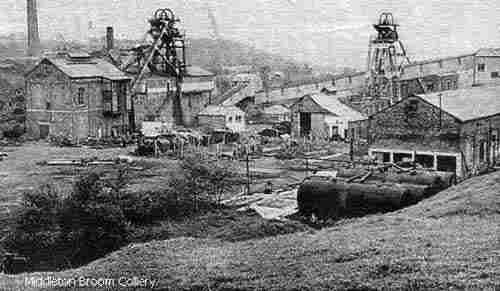

Middleton Broom Colliery (1808?-1968)

|

Used with kind permission of Leodis photographic archive of Leeds |

The estate became heavily encumbered by mortgages, however, and the High Court of Chancery decreed that the Brandling's estates should be sold to pay off their creditors in 1851. Before this was done, Ralph Henry Brandling died in 1853, to be followed by his son, Charles John, in 1856. The estate and colliery was then overseen by Brandling's Trustees between 1856 and 1863.

The latter sold parts of the Middleton estate to Francis William Tetley, of the Leeds brewing family, between 1864 and 1867. He then formed the Middleton Estate and Colliery Co. in 312 shares

Little is known of these partners, but John Rhodes owned Snydale Colliery at Featherstone, and Edmund Maude took up residence at Middleton Lodge.

Shares Francis William Tetley 76 John Rhodes 76 Joseph Ogdin 76 Edmund Maude 76 Charles Ryder 2 Fairfax Rhodes 2 George March 2 William Henry Maude 2

The company continued working the Middleton Little (32 metres) and Main (89.6 metres) seams, but they were nearing exhaustion and around 1900 the shafts were deepened to the Low Moor Better Bed at a depth of 246 metres. This gave access, in descending order, to the Blocking, Beeston, Crow, Low Moor Black Bed and Better Bed seams.

Middleton Park is crossed by two near parallel faults, running south-west to north-east, which have thrown down the coal between them to form a graben around 270 metres across. The seams within it dip to the north-east, so the graben's southern end was worked from fairly shallow shafts. The deeper reserves could not be won from Broom Pit, so in the later 19th century, Middleton New Pit was sunk from a point near what is now the South Leeds Academy. Until 1901 the details of New Pit were included with those for Broom Pit.

The following seams were worked principally down dip from the shafts:-

New Pit closed in 1921, but was retained as a pumping pit until at least 1945.

1903-1912 40 Yards 1903-1912 Blocking 1903-1923 Beeston 1906-1921 Better Bed 1913-1921 Crow 1919-1921 Flockton 1920-1921 Black Bed

By 1923 the company Directors were:

Of the above, Charles H. Merivale, a mining engineer, was General Manager. The colliery manager was Percy Littlewood from 1921 to 1940.

T.H. Churton Allerton Hill, Chapel Allerton, Leeds F.J. March Ockbrook Grange, nr. Derby J.E. Maude C.H. Merivale Middleton Hall, Middleton, Leeds F. Rhodes A. Hayes Sadler, Admiral 11, Ashley Place, London, S.W.1 A. Titley C.J. Dixon, (Secretary) Ebor House, Middleton, Leeds

During 1943 the colliery was taken over by Middleton Broom Colliery Ltd, itself a subsidiary of Briggs Collieries Ltd, which owned collieries in the Leeds, Wakefield and Pontefract area. Its directors were:

R.M. Currer-Briggs had been a director of Henry Briggs, Son & Co. Ltd which became Briggs Collieries Ltd around 1939/40. C.J. Dixon was both the General Manager and Company Secretary. The company owned the nearby East Ardsley colliery, as well as others around Normanton.

R.M. Currer-Briggs Norwood Hall, Farnley, Otley C.J. Dixon Ebor House, Middleton, Leeds 10 C.H. Merivale Welham House, Castle Cary, Somerset R.J. Shaw Royds House, Mirfield, Yorkshire

Seams worked - for List of Mines

The faces at Middleton Broom in the 1950s were around 140 metres long, with a central main gate and a return gate at either end. The face was supported by timber props and bars. The coal was undercut by a machine to a depth of about 1.8 metres, and shotholes were bored to a similar depth every two metres or so. A conveyer belt was then laid on each half of the face, both feeding onto a gate conveyor in the main gate. The latter took the coal away from the face to the end of the loco haulage, where it was loaded into mine cars and taken to the pit bottom.

Thickness (ins) 1888-1901, 1911 Middleton Little 42 1888-1900 Middleton Main 54 1903-1951 Crow 18 1903-1911, 1913-1951 Beeston 33 1903-1941 Better Bed 7 (plus fireclay) 1903-1968 Black Bed 28 (plus ironstone) 1912, 1918-1919, 1937-1940 Bottom Brown Metal 18 1919 Five Quarter 45? 1920 Three Quarter 27? 1921-1922 Blocking 16

The shotfirer then loaded the holes with explosive and stemmed them. The shots were then fired and this brought the coal down and broke it up. The colliers then each took a length of face and began shovelling the coal onto the conveyer. Any coal still adhering to the face or roof was got using a short pick. The wooden props and bars would be reset under the freshly exposed roof and the face would thus advance. The roof behind the face was allowed to collapse into the gob. The process was repeated daily. Lose stone was used to build gate-side packs in order to reduce the weight on gate supports.

Under the National Coal Board only the Black Bed was worked after 1951. By 1968, however, the Board was culling its marginal collieries, and six were to be closed in that part of the West Riding in 1968. Middleton Broom was one of them and closed because of "exhaustion of economically workable reserves" on May 17th, when the Coal News said it was 89 years old.

Further reading:

- NMRS Records, Gazetteer of British Collieries

- London Gazette 29 August 1851 Page 2223

- 1923 Colliery Year Book and Coal Trades Directory, The Louis Cassier Co. Ltd

- 1947 Colliery Year Book and Coal Trades Directory, The Louis Cassier Co. Ltd

- Wilcockson, W.H. Sections of Strata of the Yorkshire Coalfield (The Midland Institute of Mining Engineers, 1950)

- Coal News, June 1968

- Roe, M. Middleton Park Community Archaeological Survey (Meerstone Archaeological Consultancy, 2008)

- Jack Gale's Mining (June 2015)