Chocks waiting to be used at Frickley Colliery 1972

Copyright © Mike Gill

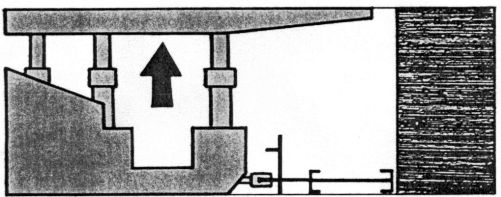

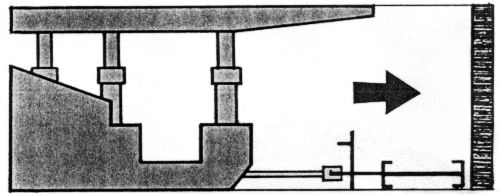

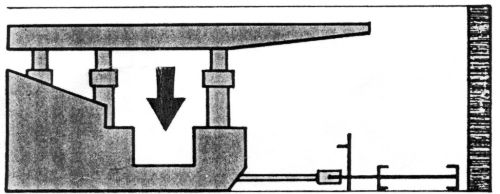

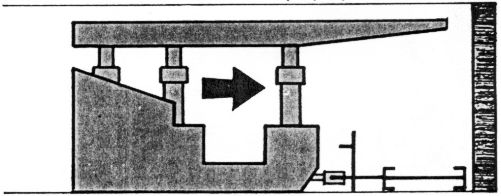

On a coalface the roof is supported by powered supports, called chocks, which are set side-by-side along the entire face.

The chocks are controlled by a number of valves which admit hydraulic fluid through hoses into the various rams within the support. This allows them to be raised tight against the roof, but yield to the movement of the roof or floor, push forward the conveyor, release the support when it has to be moved forward and, finally, move itself forward into its new position.

Face-workers remain within the travelling space and are kept safe from falling rock or coal.

How powered supports work

The complete unit is so designed that by operating control valves the armoured flexible conveyor (AFC) and chocks are to their new positions without hindrance to coal-getting.

Return to previous page