| COLLIERY | JOHN PIT | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LOCATION | Standish Lower Ground, approx. 1¾ miles west of LNWR West Coast Main Line and 1100 yards north of Leeds & Liverpool Canal. | ||||||||||

| OWNERS |

|

||||||||||

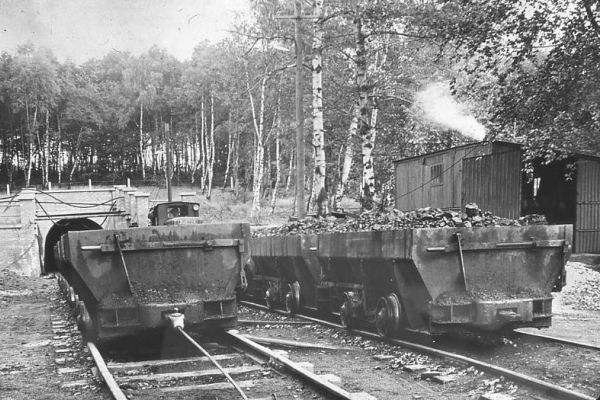

Standish Hall Drift c1950

Used with kind permission of Pitheadgear

Shafts

Commenced c1836 and sunk to Wigan Four Feet Mine at 129 yards. Abandoned.

Two shafts sunk to Cannel Mine by Standish & Shevington Cannel Co., producing cannel by 1858

No.1 Pit – Downcast and coal winding, 10 feet diameter. Deepened to Haigh Yard Mine at 359 yards, 1871. Seams intersected – Wigan Five Feet, Wigan Four Feet, Wigan Six Feet, Cannel, King, Haigh Yard.

Seams not intersected – worked by tunnelling through the Shevington Fault: Pemberton Yard, Pemberton Five Feet, Pemberton Two Feet, Pemberton Four Feet.

Lower seams exhausted by 1932. Lower part of shaft filled up and plug (water seal) inserted after 1932, at 181 yards from surface.

No.2 Pit, Sunk to Cannel mine as upcast shaft at 277 yards from surface. Lower portion filled up and plug inserted post-1932, at 186 yards from surface.

Winding

Twin cylinder horizontal winding engine located between shafts, winding one cage in each, 20 inches x 48 inches, slide valves, Stephenson link motion, ball handle reverse. Flat winding ropes 33/8 inches x 11/16 inch, rope reels 8 feet 4¾ inches diameter bare, flywheel acted as brake path. Foot operated band brake initially, steam brake added later. VISOR overwind/overspeed controller fitted, later replaced by Melling’s controller.

Cage in downcast shaft for coal winding, cage in upcast for counter-balance only. Two 11/8 inch diameter wire rope conductors per cage.

Wooden headgear No.1 Pit, 45 feet high to pulley centre, single 9 feet diameter pulley.

Double deck cage, 7 cwt. capacity tubs, 2 tubs per deck.

Wooden headgear No.2 Pit, 41 feet 9 inches to pulley centre, single 9 feet diameter pulley.

Underground Haulage

Two engines at surface for operating endless rope haulages. Later replaced by underground electric haulers.

Screens 8½ inches x 12 inches inverted vertical engine, later replaced by electric motor drives.

Fitting Shop

7 inches inverted vertical engine, later replaced by electric motor.

Pumping (1950s)

Two, run and standby, Mather & Platt centrifugal pumps, 380gpm., static head 393 feet. 130hp. motors, 2200 volts, AC, 4-pole.

Ventilation

Furnace at No.2 Pit until 1920.

Linked in 1920 to Taylor No.2 Pit, via, Pemberton Five Feet Mine. Taylor No.2 became common up cast shaft with fan.

Boilers

Originally two egg-end boilers. 50psi. Replaced by two Lancashire boilers 8 feet x 30 feet, and one Lancashire boiler 7 feet x 28 feet, working at 65psi. Square section chimney 80 feet high. Boiler feed, Cameron pump 7 inches x 6 inches x 5 inches, and Cameron pump 12 inches x 10 inches x 6 inches. Feed water heater 7 feet diameter and 28 feet high plus chimney.

Seams Worked (from Standish Hall Drift, 1954)

Crombouke (Ince Four Feet), Ince Seven Feet, Pemberton Yard (Ince Furnace), Pemberton Two Feet.

Workforce (Standish Hall Drift, 1954) – U/G 461, S/F 82.

CLOSURE

John Pit linked to Standish Hall Drift (opened 1950) in 1953.

Remaining reserves thereafter worked from drift mine.

John Pit closed April 1954.

Copyright © NMRS Records: G. Hayes Collection

Return to previous page