The Grassington Grit coal has been extensively worked on Redmire, Preston and Bellerby Moors. On the latter moor, the seam is cut off to the east by a fault which almost follows the Leyburn to Grinton road. Almost immediately beyond the fault, the coal outcrops again and has been worked by Bellerby Colliery. The seam also outcrops on the southern edge of Grinton Moor, at Coal Pit Moor, where it was being worked by Roger Hillary in the 1670s. Hillary’s family were then said to have worked the coal without interruption since 1622, when his grandfather had purchased the wastes and other lands from Henry Simpson. Caleb Readshaw was still working Grinton Colliery in the 1750s.

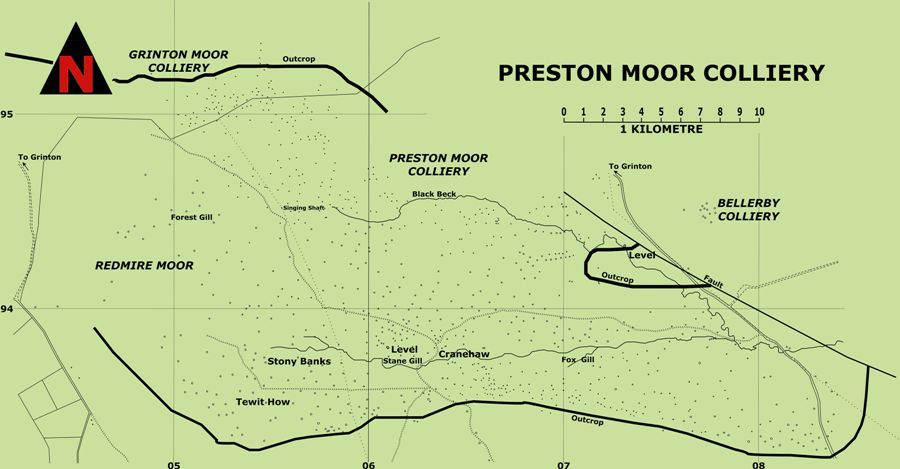

The map of the coalfield demonstrates the large number of shafts used to work this shallow seam. The shafts are generally fairly widely spaced, but nearer the outcrop they are much closer together. This agrees with a model developed for the way in which the Middleton Main Seam was worked at Middleton Park, near Leeds. There, as on Preston Moor, groups of closely spaced shaft mounds exist near the seam’s outcrop, probably where the cover was less than 20 metres above the coal seam. These, it was felt, were probably bell pits. As the depth of cover increased, the shafts were found to become more widely spaced and were interpreted as having served pillar and stall workings.

Preston Moor or Scarth Head Colliery, as it was originally known, may date from the building of Bolton Castle c1300 and was well established by the 16th century. In the 17th century enough coal was being produced to supply much of Wensleydale and parts of Swaledale as well. Output tended to fluctuate wildly, however, because the lack of geological knowledge meant that areas were often exhausted before new ones were developed or necessary adits driven. The urgent need to prospect for new areas of coal was demonstrated in 1761, when the Duke’s agents reported that:-

“The ground throughout the whole moor has been slit and the coals taken. And what coals has been raised for twenty years last past, are the pillers which has been formerly left to support the roof which are taken away and now supported with wood”.

In the late 18th century, a program of boring was begun in order to prove the northern extent of the seam. The first borings showed the coal to be 18 inches (0.45m) thick, but subsequent holes, on higher ground to the north, did not find the seam at the expected depth because it had been dropped by a fault. On parts of Preston Moor a second, unworked, seam around three inches (0.08m) thick was said to be present.

A drainage level, begun in November 1798 and driven northwards from Staingill, soon encountered faults. One of them, either Mavel or Cranebottom Vein, carried lead ore, which presumably helped to cover some of the costs, but the level was not finished until May 1801 when the colliers were “getting coals very fast”.

It is often said that the coming of a railway was death to pits working the thin Dales seams, but Ian Spensley has demonstrated that this was not always so. Because the North-Eastern Railway Company held a monopoly of supply in Wensleydale, it was able to fix an inflated price for supplying Durham coal, which meant that some small pits remained competitive.

Gill, M.C. “Great Dales Coalfield, Eastern Areas” British Mining No.86 (2008), pp.68-108

Spensley, I.M. Mines and Miners of Wensleydale, The author, 2014

Tyson, L.O. & Spensley, I.M. with White, R.F. The Grinton Mines (Including Fremington and Ellerton), British Mining No.51, 1995

Roe, M. Middleton Park Archaeological Survey, Season One, Interim Report for the Friends of Middleton Park, May 2007