| COLLIERY | PEMBERTON | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| LOCATION | South of Pemberton station on the L&YR Wigan – Liverpool line. | ||||||||

| OWNERS |

|

||||||||

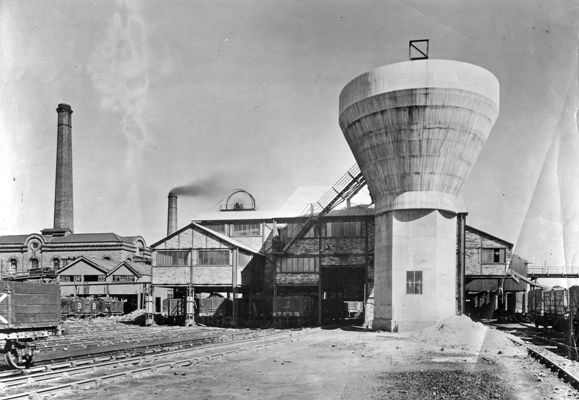

Pemberton Colliery

Chance coal washery and cone built by James Anderson Used with kind permission of Pitheadgear

Shafts

Bye Pit, sunk c1820, 130 yards to Pemberton Four feet Mine, 140 yards into sump, 10 feet diameter.

Engine Pit (pumping), sunk c1820 to approx. 10 yards below Pemberton Four feet Mine. Deepened to 192 yards in 1873.

King Pit – Commenced 1867, reached Arley Mine (Orrell Four ) at 629 yards on 2 September 1870. Sunk 11 yards further into sump. 18 feet feet diameter. 69 yards of German tubbing inserted from approx. 50 yards down shaft. Originally the upcast shaft.

Queen Pit – Commenced 1867, 16 feet diameter, sunk to Arley Mine. 52¾ yards of English tubbing inserted from approx. 50 yards down shaft.

Prince Pit – Commenced 1898, first coal wound January 1901. 18 feet diameter to 440 yards, then 15 feet diameter to Arley Mine. (This section ventilation only). Replaced King Pit as up cast shaft

New Venture Pit – Sunk 1910 – 1913, to 511 yards, 14 feet diameter.

Summersales Pit – Sunk 1944 – 1945, 12 feet diameter.

Winding

Bye Pit, single cylinder horizontal engine 21 inches x 42 inches, slide valve on top of cylinder, relieving cylinder and piston on top of steam chest, loose eccentric and gab reversing gear, flywheel, parallel drum 9 feet diameter. Winding ropes 1 inch diameter, two – 8 cwt. tubs in double deck cages, pitch pine cage conductors 4 inches x 3 inches, two to each cage. Engine installed 1856. VISOR overwind/overspeed controller fitted 1892.

King Pit, twin cylinder horizontal engine, 36 inches x 72 inches, Haigh Foundry, 1870. Cornish valves, Gooch link motion, eccentrics on outboard shafts with drag link drive from crankpins. VISOR overwind/overspeed controller. Original winding drum 15 feet 2 inches diameter plain on one side for winding from Wigan Nine, other side conical 15 feet 8 inches to 19 feet 4 inches diameter, winding from King and Cannel Mine. Six tubs 8 cwt capacity wound in three-deck cages. Winding drum later altered to parallel 19 feet 4 inches diameter. Headgear – lattice girder, wrought iron, with 18 feet diameter pulleys. Four iron wire rope conductors to each cage. Original winding cycle time 85 seconds.

Queen Pit, twin cylinder horizontal engine by Robert Daglish, St Helens, 1870, 36 inches x 72 inches, Cornish valves, link motion eccentrics on outboard shafts with drag link drive from crankpins. VISOR overwind/overspeed controller. Conical winding drum, 48 tons, 19 feet 8 inches to 30 feet 10 inches diameter, centre brake path, steam brake and strap brake. Winding depth from bank 638 yards, winding ropes tapered 1½ inches to 1¾ inches diameter. Six tubs, 8 cwt. capacity in three-deck cages. Cage conductors flat bottomed (Vignoles section) steel rails, two per cage on one side. Headgear, wrought iron lattice girder, 68 feet 6 inches to pulley centres, pulleys 18 feet diameter. Winding cycle time (1875), 90 seconds.

Prince Pit, twin cylinder horizontal engine, 30 inches x 60 inches, rebuilt by Wood & Gee from two single cylinder winding engines ex. Rose Bridge Colliery. Cornish valves, new crankshaft and new parallel winding drum 15 feet 6 inches diameter. Rebuilt Worsley Mesnes Ironworks, 1939, with piston valve cylinders and Worsley Mesnes brake gear. Headgear of Oregon pine 65 feet high. Replaced in 1939 by 73 feet high steel headframe.

Summersales Pit, 30 horse power electric winder, with automatic pushbutton control by banksman. Wound two – 8 cwt tubs in 25 seconds, 80 feet from shaft bottom to bank.

NOTE – All winding ropes fitted with Ormerod detaching hooks.

Underground Haulage

Arley Mine twin cylinder horizontal engine 16 inches x 30 inches, geared 1:2 to two 6 feet diameter drums for main and tail haulage 2040 yards long. 35 tubs per journey. Engine compressed air operated.

Orrell Five feet Mine, compressed air twin cylinder horizontal engine 6 inches x 12 inches, single drum 3 feet 6 inches diameter for tail rope – tubs hauled inbye. Full tubs run out bye by gravity with rope.

Cannel Mine, compressed air twin cylinder horizontal engine, two drums for main and tail haulage.

Compressed air twin cylinder horizontal engine 6 inches x 12 inches, geared 1:2, single drum for tail rope only.

Wigan Nine, compressed air twin cylinder horizontal engine 12 inches x 24 inches, double geared 1:10 operating endless rope haulage via. tunnel in Wigan Four.

Orrell Five, twin cylinder horizontal steam engine located at top of Queen Pit. 16 inches x 30 inches, geared 1:2, two drums for main and tail haulage.

Pemberton Four, twin cylinder horizontal steam engine in Bye Pit, near shaft, 16 inches x 36 inches, geared 1:2, two drums for main and tail haulage.

Pemberton Five, same arrangement as Pemberton Four.

From 1906 approximately 250 ponies worked underground over a period of some 25 years.

Electric haulers later replaced the steam haulage engines, the electric engines being placed underground.

Summersales, fitted out from the beginning with electric endless rope and direct rope haulage.

Pumping

Pumping

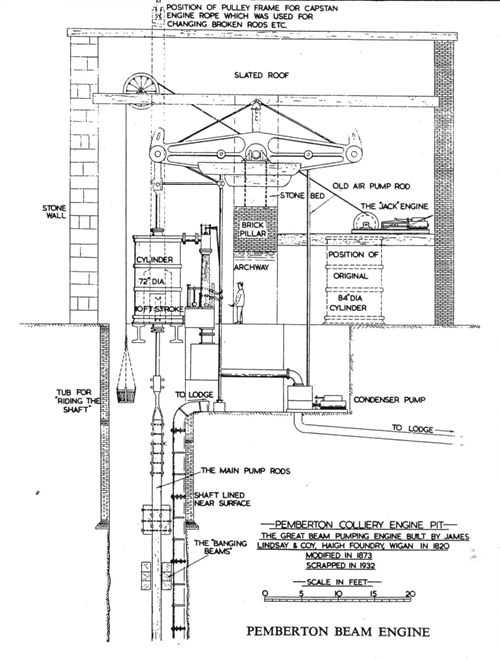

Engine Pit, 84 inches x 10 feet beam pumping engine by Haigh Foundry, 1820, rebuilt 1873 with new cylinder 72 inches x 10 feet located over shaft with piston rod directly coupled to pump rods. New valve gear and air pump provided. Beam retained to operate valve gear and air pump. Beam 29 feet long.

Bottom pump lift 70 yards, 20 inches bucket pump. Top lift 20 inches ram pump lifting 120 yards. Engine worked 6 to 7 strokes per minute approx. 18 hours per day.

Cataract control on valve gear.

Wigan Nine, compressed air operated duplex horizontal pump, located underground. 14 in x 30 in x 4 inches.

Wigan Four, similar to Wigan Nine feet arrangements.

Pemberton Four, Worthington duplex tandem compound steam pump installed underground at the Engine Pit, 1899, 23 inches + 38 inches x 24 inches, double acting pumps 12½ inches diameter. Engine replaced top lift of beam pumping engine.

Bye Pit, two electric 175hp. Rees Roturbo multistage centrifugal pumps installed 1917. Replaced Worthington and the beam pumping engines. Supplemented 1928 by Mather & Platt turbine pump.

King Pit, Two 220hp. Mather & Platt turbine pumps installed 1938 in tunnel from King Pit with borehole connections to Engine Pit sump. Replaced Bye Pit pumps.

Wigan Four feet and Wigan Nine, compressed air pumps replaced in 1934 by electric three-throw ram pump in the Four feet and a turbine pump in the Nine.

Summersales, Four Mather & Platt “Medivane” centrifugal pumps, 30hp. motors, 300gpm. each.

Ventilation

Guibal fan installed 1872 by Baker & Valliant, Wigan, 46 diameter by 14 feet 10 inches wide. 314,000cfm. at 2.8 inches wg. at 48rpm.

Duplicate engine 36 inches x 42 inches, Cornish valves.

1910 – Davidson of Belfast SIROCCO fan installed, 14 feet 7 inches x 6 feet 2 inches, 175hp. electric motor, 8 – 1½ inches cotton ropes. 300,000cfm. at 2½ inches wg. (stand-by fan).

Summersales, Walker Bros. AEREX 2-stage axial flow fan, 35.3 inches diameter, 30,OOOcfm., 8 inches wg at 2150rpm. 6 vee-rope drive from 50hp. motor. Later replaced by two Woods propeller fans, each rated at 30,000cfm., 45hp. motors.

Compressed Air

Twin cylinder horizontal compressor by Haigh Foundry, 1875.

30 inches (steam), 30 inches (air), x 60 inches stroke, slide valves (Meyer cut-off type). Running speed 20rpm., Flywheel 20 tons. Flywheel burst 1899.

Twin cylinder horizontal compressor by Longbotham of Wakefield, 19 inches x 30 inches (steam) driving two air cylinders 20 inches x 60 inches through reduction gearing. Not a success replaced by a Daglish conventional slow speed engine.

1911 – Mixed pressure turbo-compressor, C.A. Parsons, 5000cfm., live steam at 90psi.

1914 – Mixed pressure turbo-compressor as above.

1938 – Electrically driven turbo-compressor replacing steam driven compressors. British Thomson-Houston, Rugby, 1075hp., 5000cfm.

Two electrically driven reciprocating compressors installed at Summersales. Alley & McLellan, 1000cfm., 199hp.

Electricity

Lighting set installed 1891 by Mercier, Corlett & Co., Wigan.

Single 12in. cylinder inverted vertical engine with link belt drive to Crompton DC generator.

Two further lighting sets installed c.1900, high speed single cylinder engines.

Two Belliss & Morcom compound engine/alternator sets, 550 volts AC.

(1918), National 300hp. gas engine and Crompton alternator.

(1928), National 400hp. gas engine and Crompton alternator.

Gas engines replaced steam engine generating sets, and ran on coke oven gas.

Site generation of electricity discontinued 1937. Electricity obtained from public supply.

Boilers (1892)

King & Queen Pits, twelve Lancashire boilers 7 feet x 28 feet with cross tubes, 60psi., hand fired. Fitted with lever and weight safety valves and Hopkinson high steam/low water alarm valves. Lagged with “composition” and roofed over. Chimney octagonal section 168 high.

Bye Pit, – seven Lancashire boilers and two egg-end boilers. 50psi. Egg-end boilers fired on coke oven gas.

1899 – Two further Lancashire boilers installed, steel, 8 feet x 30 feet, 120psi.

1920 – Thirty-six Lancashire boilers in use.

Workshops (1867-1932)

Single cylinder vertical engine 16 inches x 30 inches, two Lancashire boilers, octagonal chimney 90 feet high.

15 cwt compressed air hammer installed early 1900s.

Workshops closed 1932, and smaller workshops established.

Stables – Single cylinder engine and vertical boiler.

Accidents & Disasters

On the 24th April 1830 there was an explosion at the colliery with the loss of nine lives.

Seams Worked

1931 – Wigan Four, Wigan Five, Wigan Nine, Arley Yard.

1954 – Summersales – Wigan Five, Wigan Four, Trencherbone (Wigan Nine)

Output & Workforce

1931 – 400,000 tons per annum. U/G 1350, S/F 470

1954 – Summersales – U/G 159, S/F 44

CLOSURE

November 1946, except Summersales Pit.

Summersales, 18 March 1966.

Pumping continued at Pemberton until 1959.

Copyright © NMRS Records: G. Hayes Collection

Return to previous page