Hafodyrynys, Glyn Valley (24750045, 24699752, 24619776)

Hafodyrynys, Glyn Valley (24750045, 24699752, 24619776)

There was a Hafodyrynys Colliery working in 1878 and 1880 under the ownership of E. Jones. There is no mention of Hafodyrynys again until 1911 when the Crumlin Valleys Colliery Company commenced sinking the two shafts of the Colliery. The sinking of the shafts was completed in 1914.

The downcast ventilation shaft was used for winding and was 302 yards deep and 19 feet in diameter. The upcast ventilation shaft was 294 yards deep and 16 feet in diameter. The winding shaft could only raise one tram at a time which took 37 seconds. The maximum winding rate for a shift was 730 trams. The manager at that time was A.F. Linton, while the manager in 1918 was J. Jenkins and in 1930 it was William Daniel.

The area that it could work was severely restricted by the northerly down throwing Glyn Fault. This geological fault extended for seven miles from just west of Pontypool and to just south of Mynyddislwyn church. It ran along the Glyn Valley and in the Hafodyrynys Colliery area was at its deepest, dropping the seams 280 feet. Two miles further on to Pontypool it disappeared. It abandoned the Lower-Three-Quarter seam as early as December 1921.

In December 1920 Partridge, Jones and John Paton was formed by the Amalgamation of the Crumlin Valley Colliery Company with Partridge, Jones, who then owned Crumlin Navigation, Gwenallt, Blaenserchan and Llanhilleth collieries. The new company; Partridge, Jones and John Paton, Limited, was ‘to carry on the business of colliery proprietors, coal merchants, &c., with a capital of £3,000,000.’

Partridge Jones and Company began trading in 1864 at the Varteg Works with a partnership of Partridge, Bailey, Jones and Messrs Henry. In 1874 they expanded and controlled the Pontnewynydd Iron Works, Golynos Iron Works, Abersychan Iron Works and both Plas-y-Coed and Cwmsychan collieries. In that year a limited company was formed.

By 1899 the company was owned by a total of ninety shareholders, of which only 4.4% were working-class while 44.4% were classed as not employed, ie gentlemen and ladies. The professional classes accounted for 20% of the shares, exporters, merchants, brokers and agents had 8.9%, while the rest were divided between financial, retail and clerical sections of society.

John Paton, by 1895, was one of the principal shareholders in the Pontnewynydd Sheet & Galvanising Works with Partridge, Jones, and with the death of W.B. Partridge in 1909 obtained a seat on the board of Partridge, Jones & Co. In 1920 the interests of both companies were amalgamated.

The company was based at 88, Dock Street, Newport with the directors being; John Paton, W. Rees Jones, H.J. Smith, H.F. Partridge, Sir John Hamilton Kenrick, William Houldsworth McConnell, M. Deacon, C.E. Evans and A.J. Joshua. The company secretary was J.A. Chapman. In 1935 Partridge, Jones and John Paton Limited bought up the mining interests of the Ebbw Vale Steel, Iron and Coal Company, and as well as the 12 pits directly owned by the Ebbw Vale Company, took control of its subsidiaries; John Lancaster & Co. Powell’s Tillery Steam Coal Co. Newport Abercarn Black Vein Steam Coal Co. In 1937 the Tirpentwys Black Vein Steam Coal & Coke Company was added to the fold making P. J & JP one of the giants of the South Wales Coalfield controlling 21 pits and 4,500,000 tons of coal annually. John Paton became Chairman, and amongst the directors were W. Rees Jones and H.P. Partridge.

In 1923 the Crumlin Valleys Colliery Company was based at Pontypool and produced house, manufacturing and steam coals from both this colliery and from the Glyn Pits, although there were significant differences in the manpower with the Glyn Pits employing 32 men, and Hafodyrynys employing 769 men. The directors of the company were; W.R. Jones of Pontypool, G.H. Kenrick of Birmingham, John Paton of Abergavenny, E. Steer of Malpas and J.E. Ward of Wiltshire. By 1933 the company office had moved to Hafodyrynys Colliery, and manpower at this pit had increased to 936, with the same figure of 32 maintaining the Glyn Pits. The new addition to the company, Albion Road was being opened up and employed three men. There was also a change within the directors with Messrs Steer & Ward absent from the list.

In 1935 Hafodyrynys Colliery employed 120 men on the surface and 850 men underground. The manager was I.L. Williams. In 1938 and 1945 it was W.J. Rees. In 1943 it employed 545 men working underground in the Meadow and Big veins and 121 men working at the surface of the mine. In 1936 pithead baths were constructed at this colliery, they had room for 988 men. Up until 1947 there were about fifteen fatalities at this colliery, eight of them were through roof falls and another three were from haulage accidents.

On Nationalisation in 1947, Hafodyrynys Colliery was placed in the National Coal Board’s, South Western Division’s, No.6 (Monmouthshire) Area, and at that time employed 114 men on the surface and 514 men underground working the Meadow Vein (Yard/Seven-Feet) and Big Vein (Four-Feet) seams. The manager was still W.J. Rees (he was still there in 1949). In 1956 out of a total manpower of 550 men at this colliery 214 of them were deployed at the coalfaces, this coalface figure dropped to 186 men in 1958, but with the New Mine in operation in 1961 there were 728 men employed at this colliery with 287 of them working at the coalfaces.

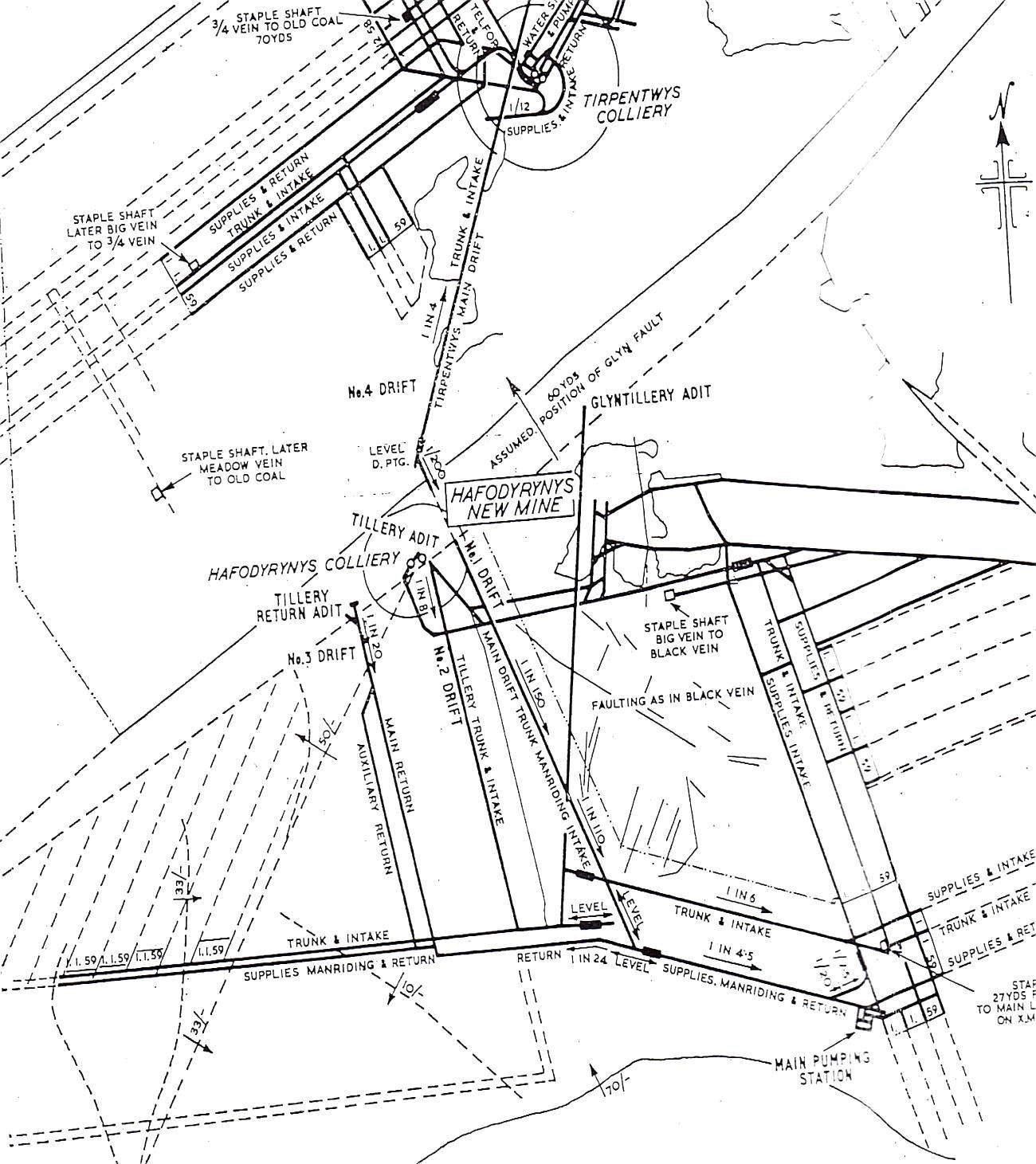

In 1956, after less than a decade following Nationalisation the NCB started to carry out its ‘rationalisation’ of the mines in the area. Many of the smaller ones such as Llanmarch, Cwmtillery Red Ash and the Rhiw Colbren’s had already closed and the closure of West Blaina Red Ash Colliery in 1949 heralded the withdrawal of mining from the near exhausted and unprofitable collieries of the northern outcrop. Beynons Colliery at Blaina now became the most northerly mine in the Ebbw Fach Valley. To replace this lost production capacity the NCB announced a huge investment and merger plan; there were three main projects in the Monmouthshire (Gwent) section of the Coalfield: a merger of all the mines in the northern Afan Lwyd Valley centred on Big Pit, Blaenafon. A New Mine at Hafodyrynys incorporating Hafodyrynys, Glyntillery and Tirpentwys collieries, and finally the Abertillery New Mine.

In 1956, after less than a decade following Nationalisation the NCB started to carry out its ‘rationalisation’ of the mines in the area. Many of the smaller ones such as Llanmarch, Cwmtillery Red Ash and the Rhiw Colbren’s had already closed and the closure of West Blaina Red Ash Colliery in 1949 heralded the withdrawal of mining from the near exhausted and unprofitable collieries of the northern outcrop. Beynons Colliery at Blaina now became the most northerly mine in the Ebbw Fach Valley. To replace this lost production capacity the NCB announced a huge investment and merger plan; there were three main projects in the Monmouthshire (Gwent) section of the Coalfield: a merger of all the mines in the northern Afan Lwyd Valley centred on Big Pit, Blaenafon. A New Mine at Hafodyrynys incorporating Hafodyrynys, Glyntillery and Tirpentwys collieries, and finally the Abertillery New Mine.

It was decided by the National Coal Board to abandon the old Hafodyrynys pits and create a new mine. The old shafts were filled in August 1965. New inclined drifts were sunk, the No.1 Drift went to a depth of 232 metres, and the No.2 Drift to a depth of 247 metres and the No.4 Drift was driven to a depth of 418 metres and ran for a length of 1,665 metres with a 4.26 metre diameter roadway.

The new colliery buildings and washery were designed with modern buildings and equipment for maximum efficiency. Architecturally, they were influenced by the functionalism of pre-war collieries in Germany designed by the Bauhaus architect Peter Behrens, by the sinuous forms of the Festival of Britain, and possibly by the nearby Brynmawr Rubber Factory. All the buildings had reinforced concrete frames filled with brick or glass panels and flat, curved or waveform concrete roofs. Washery plants were key elements in post-war efficiency improvements, as only half of British coal output was being washed in 1945. The washery at Hafodyrynys contained equipment for extracting coal dust from slurry and drying the remaining waste before tipping: processes that were rare before the 1950s. It was built entirely of reinforced concrete with continuous glazed panels.

Surface facilities were modernised to service the Hafodyrynys, Glyntillery and Tirpentwysmines and the mine was expected to raise 800,000 tons of coal every year with manpower of 2,283 men out of expected reserves of 53 million tons consisting of the following;

- Seam – Thickness – Reserves

- Tillery – 36 inches – 2,639,000 tons.

- Elled – 36 inches – 1,289,000 tons.

- Big Vein – 55 inches – 12,927,000 tons.

- Upper Three Quarter – 33 inches – Not workable.

- Lower Three Quarter – 42 inches – 13,530,000 tons.

- Meadow Vein – 57 inches – 6,243,000 tons.

- Old Coal – 40 inches – 17,148,000 tons.

This work was completed in 1959 at a cost of £5.5 million. The railway sidings had a capacity for 414 empty waggons and 317 full (12 ton) waggons. Later Blaenserchan Colliery’s output was brought up the new mine. The Colliery Guardian dated 9/4/1959 reported that the roadway to Tirpentwys (No.4 Drift) was one of the fastest to be driven at that gradient in Britain. It was 1,821 yards long and driven down at a gradient of 1 in 4 using fourteen feet arches for supports. It was completed in 66 weeks and had a 600 h.p cable belt installed to bring up the coal. Following the introduction of power loading at the coalfaces in this colliery the output per man shift more than doubled, it reached 36 hundredweights by May 1956. In the NCB’s 1957 power-loading survey one coalface was listed at Hafodyrynys, the B2 which was worked from the old pits. It was working in the Big Vein and had a thickness of 68 inches which included 8 inches of clay, and a length of 684 feet. There were three roadways into the coalface; the left-hand road was the return ventilation road, the middle road was for supplies and the right-hand roadway was the conveyor road. All were supported by fourteen feet steel arches. The coalface roof support was by Dowty props and metre bars which were spaced two feet apart.

There were 52 men working on this coalface and coal cutting was by Anderton disc which had a 40-inch cut and a speed of nine feet three inches per minute. The daily advance was 31 inches, one of the lowest in the report. The NCB must have been impressed with the coalface through and allowed a thirteen man delegation of Russian mining engineers to visit it. The coal was transported to a five feet diameter spiral Shute which also acted as a 27-ton reserve bunker. The coal was transported to the pit bottom in journeys of 24 x 22 hundredweight trams.

The 1962 annual review reduced the stage 2 estimate of planned annual output, overall productivity and profitability respectively from 845,000 tons to 465,000 tons, 31.6 cwts to 24.6 cwts and converted profits of 21/5d per ton to losses of 13/- per ton. Full output was then expected in 1963, four years later than the stage 2 expectation. The 1963 annual review has recently been received at headquarters and in view of the substantial shortfall in results now expected as compared with the stage 2 estimates The production department are carrying out an on the spot investigation of this project.

On the 6th of May 1962, a roof fall in the main roadway killed Lyndon Nicholls aged 29, Reginald Baker aged 29, Melvyn Morgan aged 22 and David Owen aged 48 years.

Hafodyrynys’ coals were generally classed as type 501 and type 602 High Volatile Coals, of strong to medium caking. They were used for coking blends and for power stations. On the 2nd of March 1966 at a meeting between the NUM and the NCB the NUM wanted to continue working the Meadow Vein and also re-work the Big Vein, the NCB quoted the following figures and proposed closing the Hafodyrynys section of the New Mine.

Year – Output per man shift – Loss per ton

- 1963/64 – 17.1 cwts – £3.40

- 1964/65 – 23.9 cwts – £1.69

- Half year to Sept 1965 – 23.8 cwts – £2.28

- Dec quarter – 16.3 cwts – £6.25

In another meeting held on the 8th of March 1966, the NCB rejected the NUM’s proposals stating that they would cost £600,000 and that the money would be better spent elsewhere. The New Mine proved something of a white elephant, and never reached its full potential. The Hafodyrynys section closed on the 7th of July 1966,

Tirpentwys in 1968 and Glyntillery in 1975. Of the 277 men at Hafodyrynys on closure 229 were transferred mainly to Tirpentwys 90, Glyntillery 34, Blaenserchan and Six Bells 17 each, Oakdale 5, the Celynen’s 4 each, Llanhilleth 2 & Crumlin Navigation 1.

The site was cleared in 1985.

Some Statistics:

- 1912: Manpower: 96 sinking.

- 1915/6: Manpower: 250.

- 1918: Manpower: 574.

- 1919: Manpower: 520.

- 1920: Manpower: 700.

- 1923: Manpower: 924.

- 1924: Manpower: 994.

- 1925: Manpower: 700.

- 1926: Manpower: 900.

- 1928: Manpower: 928.

- 1930: Manpower: 928.

- 1932: Manpower: 900.

- 1934: Manpower: 998.

- 1935: Manpower: 970.

- 1937: Manpower: 955.

- 1938: Manpower: 826.

- 1940: Manpower: 975.

- 1945: Manpower: 666.

- 1947: Manpower: 628.

- 1948: Manpower: 583. Output: 120,000 tons.

- 1949: Manpower: 617. Output: 137,000 tons.

- 1950: Manpower: 616.

- 1953: Manpower: 510. Output: 130,000 tons.

- 1955: Manpower: 500. Output: 123,792 tons

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page