CAMBRIAN. Rhondda, Glamorganshire. 17th. May, 1965.

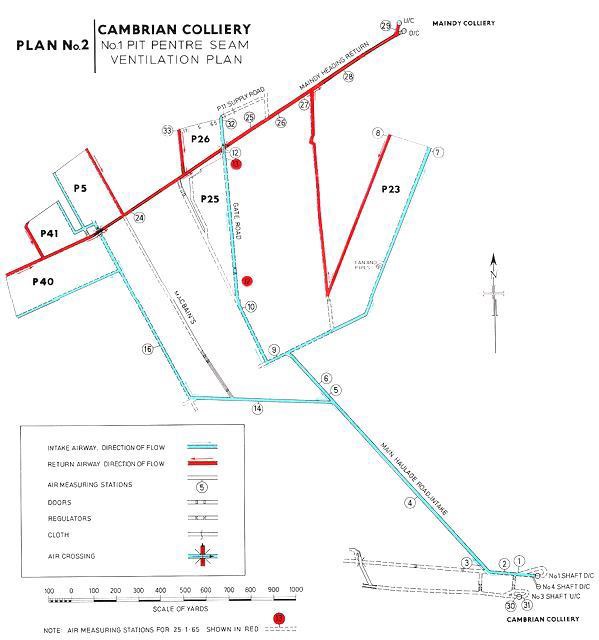

Cambrian Colliery was in the no. 3 Area of the National Coal Board’s South Western Division and was near the village of Clydach Vale in the Borough of Rhondda about 20 miles North West of Cardiff. There were four shafts at the colliery. The No.1 was downcast, 16 feet in diameter and sunk to the Five Feet Seam at a depth of 506 yards. The current winding level was at the Pentre Seam at an inset at 212 yards. The Maindy shaft at a former colliery of that name was elliptical 14 feet by 12 feet and served as the upcast from the Pentre Seam workings. Nos. 3 and 4 shafts were used for working the Five Feet, Lower Nine Feet and Bute Seams. The Maindy shaft was equipped with a radial flow fan which produced 103,000 cubic feet of air per minute at 4.8 inches water gauge.

The principle officials were the Area General Manager, Mr. G. Blackmore, the Area Production Manager, Mr. G. Hodkin, the Deputy Area Production Manager (Operations), Mr. W.J. Lewis, the Deputy Area Production Manager (Planning), Mr. W.J. Strong, the Group Manager, Mr. E. Pugh, the Manager, Mr. E. Breeze and the undermanager of the No.1 Pit, Mr. L. Williams. Both Mr. Breeze and Mr. Williams were killed in the explosion. The colliery employed 816 men at the time of the accident, 654 below ground and 162 on the surface and had a daily output of 700 tons from the Pentre Seam 300 tons and from the Lower Nine Feet and Bute Seams.

The colliery was, and always had been, a safety lamp mine and had a lamp room of the “self Service” type and was equipped with 770 cap lamps, 129 flame safety lamps of which 59 were of the internal re-lighter type and eight automatic firedamp detectors.

The Pentre Seam was 240 yards deep at the shaft and three feet thick. It was overlain by the Pentre Rider Seam about 24 feet above with coal measure shales and sandstone separating the two seams. Forty-one feet beneath the Pentre Seam were beds of sandstone, one 19 feet thick and mudstone separating these two seams. The P.26 District was about 3,000 yards from the No.1 Pit bottom and was a continuation of the P.25 district which had to be stopped as it approached the main return airway which was known as Maindy heading Return. It was formed by extending the P.25 Conveyor Road as a coal heading over the Maindy Heading Return while at the same time a short drift rising at a gradient of 1 in 2.4, parallel to the coal heading was driven from the Maindy Heading return to intersect the seam. The two roads were connected to form a face which came into full production in January 1965. At the time of the accident the face was 192 yards long and was advancing to the north on a rising gradient of 1 in 33 while the gradient cross the face was rising at 1 in 17 from the intake gate.

The face machinery consisted of a rapid plough worked in conjunction with an armoured face conveyor which were both driven by electricity. The intake gate which was the conveyor roadway was supported by 12 feet by 8 feet arched girders, had a coal rib on the right side and an eight-yard wide pack on the left. The return gate was the supply roadway and was supported by 10 feet wide by 8 feet arch girders, and a coal rib on the left side and an eight-yard wide pack on the right. Rippings for the roadways were taken in two sections just in advance of the face line and the main sections normally in line with the packs. The stables at each end of the face were 18 feet wide. Coal getting was carried out on the day and afternoon shifts on alternate weeks and the front sections of the rippings were taken on the night shift with the main sections on the other non-coaling shifts.

The face was “open caved” and “prop-free front” system of support was employed using handset hydraulic props contained in pairs of frames set at five feet intervals. Each pair consisted of an open frame with three props and the other with two. The frames in each pair were advanced alternately. The rest immediately in front of the gate side packs were supported by hydraulic props with metre long link bars and the roadheads by 11 feet long straight steel girders, each set to three props.

Coal from the face was delivered by an armoured conveyor on to a chain conveyor in the intake gate, which in turn, delivered on to a second chain conveyor and from there on to a 30-inch wide belt conveyor. At a loading point about 800 yards outbye the coal was transferred to 30 cwt. trams and taken by rope haulage to No.1 shaft bottom. Supplies for the district were brought from the No.2 Shaft along the main haulage road and then by way of a road called MacBains, into the Maindy Heading Return and from there into the district. Pulsed infusion shotfiring was practised in the stables while the rippings were brought down by explosives.

The ventilation of the district was by a separate split from the main intake which crossed the Maindy Heading return at an air crossing, which was known as the air bridge. On leaving the face, the air passed down the return gate into the Maindy Heading Return under the air bridge and the to the Maindy upcast shaft. Near the outbye end of the split was a pair of ventilation doors. The last statutory measurements were taken on the 26th April 1965 while the face was in full production, showing that the air available and circulation outbye of the air bridge and round the face was 23,000 cubic feet of air per minute and 8,000 cubic feet respectively. An air sample taken at the same time about 10 yards from the face showed 0.38 per cent firedamp.

The ventilation of the district was by a separate split from the main intake which crossed the Maindy Heading return at an air crossing, which was known as the air bridge. On leaving the face, the air passed down the return gate into the Maindy Heading Return under the air bridge and the to the Maindy upcast shaft. Near the outbye end of the split was a pair of ventilation doors. The last statutory measurements were taken on the 26th April 1965 while the face was in full production, showing that the air available and circulation outbye of the air bridge and round the face was 23,000 cubic feet of air per minute and 8,000 cubic feet respectively. An air sample taken at the same time about 10 yards from the face showed 0.38 per cent firedamp.

The air bridge had two openings in the floor one about nine feet square and covered with loose boards and the other about four feet square covered with a corrugated sheet. Apart from these openings, the floor of the air bridge was covered with wood boards inserted into flanges of straight girders with the intervening space to the top of the girders being filled with small dirt. At the time of the explosion, automatic firedamp detectors were not in use in the district.

The development went on without incident. There had been some difficulty arising from the fact that the props were too long for the working height of the face but the management decided to replace them and this was being done at the time of the disaster. When the face was started it was parallel to the Maindy Heading Return and so not at right angles to the intake and return gates. From the start the return end of the face had been advanced more rapidly than the intake end so as to bring it into line and at right angles with the roads and this had almost been achieved at the time of the explosion. The effect of this was to distort the line of the face and to create a situation whereby the return roadside pack did not always keep pace with the advance of the face. At the time of the disaster the pack was about eight yards behind and the air was leaving the face could not sweep into the fast end. In spite of the reduction in packing, support of the roof in this area by chocks and props appeared to be adequate.

It was said that the management were intending to complete the air bridge with a concrete floor but this had not been done. The access holes were intended to be temporary, pending the drivage of a proper connection between the intake gate and the Maindy Heading return. This had been started but other work with a higher priority was carried out and the drivage of the connection was discontinued.

At the inquiry, there was conflicting evidence about the state of the air holes but different witnesses passed the air crossing at different times and saw different conditions but the Inspector was left with the impression that the smaller of the two holes, which was equipped with a ladder, was open for most of the time. The larger of the two holes was used to pass bulky materials although on the day of the explosion it had not been opened often but the loose boards did not produce a good seal. There was also conflicting evidence about a pair of ventilating doors at the outbye end of the split. The Inspector thought that they were originally the connection with the ventilation from the P.25 face. When the face ceased production the doors were kept open except for a few occasions when it was necessary to deflect air into the P.25 district when salvage operations were going on there. They were simple regulators and in fact the air deflected into P.25 would have rejoined the main current outbye of the air bridge. Open or closed they could have had little effect on the accident.

At the inquiry, there was conflicting evidence about the state of the air holes but different witnesses passed the air crossing at different times and saw different conditions but the Inspector was left with the impression that the smaller of the two holes, which was equipped with a ladder, was open for most of the time. The larger of the two holes was used to pass bulky materials although on the day of the explosion it had not been opened often but the loose boards did not produce a good seal. There was also conflicting evidence about a pair of ventilating doors at the outbye end of the split. The Inspector thought that they were originally the connection with the ventilation from the P.25 face. When the face ceased production the doors were kept open except for a few occasions when it was necessary to deflect air into the P.25 district when salvage operations were going on there. They were simple regulators and in fact the air deflected into P.25 would have rejoined the main current outbye of the air bridge. Open or closed they could have had little effect on the accident.

On 7th May, the intake end of the face made contact with the right-hand roadhead of the old P.11 district. The confection was made at the end of the coaling shift and the deputy took immediate steps to close the small opening with brattice cloth. In succeeding shifts brattice sheets were erected in the old roadway and on Tuesday, six days before the explosion, T. Evans, a mason, began to construct a wood and cloth stopping with a door across the old roadway near to the holing. Because of a shortage of materials, the work was not completed by the weekend so on the Monday morning Evans, having acquired the necessary materials, went in to close off the remaining area of about one square yard to the stopping. He completed the work by 11.15 a.m. and then left the district.

The last coaling shift before the explosion occurred was on the afternoon of Friday 14th May. The deputy in charge, B. Pyne, who was a replacement for the regular deputy, said that the shift was normal and he did not detect any firedamp in the course of his inspections. He recalled that sometime during the shift the access holes in the air bridge were open for the passage of materials but he did not see any defects in the ventilation. The night shift of 16th-17th May with deputy C. Evans who had charge of a few men, were changing props on the face. Evans said that supplies were not brought into the district during the night and that the shift was normal in all respects.

The day shift of 17th May went underground at the usual time and arrived in the district about 7.30 a.m. H. Pope was the district overman and T.E. Davies was the deputy in charge. Apart from the work on the face that morning, there was a considerable amount of other activity. Two major operations were in progress, the transport and erection of a belt conveyor in the intake gate to replace one of the existing chain conveyors and the extension of a rope haulage system in the return gate. As a result of this activity, there were a larger number of men in the district that was usual.

Richards and P. Best, two repairers who spent the whole of the shift near the air bridge, were getting parts for the conveyor drive head up through the larger of the two holes from the Maindy Heading Return for D. Bessant and E.L.T. Jones, fitters who, with others were erecting the conveyor. They removed the bords over the large opening at about 8.30 a.m. but shortly afterwards, Pope, the overman, visited them and noted that, although the access hole was open, the materials to be passed through were not there. He gave instructing for the hole to be closed until the materials were there and the men replaced the boards while they went into the Maindy Heading Return to lead machinery parts into trams. This probably took about half to three-quarters of an hour but it was clear that from the time the materials reached the air bridge until the explosion the large access hole remained open. According to Richards, the other access hole, the smaller one with a ladder, remained open throughout the shift and this was confirmed by other witnesses.

The day shift pit overman, G. Price, said that it was normal practice for the smaller of the two holes to be open during the coaling shift and he understood that the other access hole would have been open for at least half the shift that morning. The deputy, Davies, said he found the large hole open and the men raising machinery through it when he returned to the air bridge after the completion of his first inspection at 10.20 am. He was satisfied with the state of the ventilation throughout the whole of the shift.

The extension of the rope haulage in the return gate involved the transfer of a number of sheave wheels from one side of the gate to the other. R.C. Jones, sheavesman for the mine, who was supervising this work, was in the roadway for nearly three hours from 9.30 a.m. and thought the ventilation satisfactory. As he was coming out of the road at about 12.15 p.m., two electricians passed him going inbye the door and stopping at the end of P.11 connection was completed at 11.15 a.m.

Coaling commenced normally about it was interrupted at about 9 a.m. by the breaking of the plough chain which coincided with the failure of the face telephone circuit. The fault in the system either rectified itself or was repaired by someone unknown. There was contradictory evidence as to whether ploughing recommenced but if it did it could have been only for a few minutes because at about 12.15 p.m. an electrical fault developed at the return end plough motor. The overman telephoned K. Davies, the plough operator at the return end and told him that the electricians were working on the switches at the return gate with one panel open but that the fault had not been located. Price then gave instructions for the plough to be brought down the face by the motor at the intake end. This was done but attempts to plough back up the face were unsuccessful.

When the electrical fault developed the deputy made his way up the face towards the intake end and at about 12.40 p.m. when, about 40 yards from the intake gate he met the manager and the undermanager. They told him that Price, the overman, was attending the electrical fault, but after a few minutes, the manager instructed the deputy to go and find out what was happening. Davies went to the telephone at the intake end of the face and spoke to the plough operator at the return end who said he would go and make inquiries. While the deputy was waiting at the telephone the explosion occurred.

As near as possible the time was 12.55 p.m. The deputy was struck by a violent blast which blew him backwards but he did not see any flame. Price was on his way to the telephone between the face and the air bridge was blown into the side of the road by the blast. He immediately went back to the face where he met the deputy and others but, because of the smoke and dust visibility was restricted. With the deputy he then went to the outbye telephone and raised the alarm. Shortly afterwards D. Jones at the loading point outbye was instructed to go to the P.23 District to fetch the men out from there to assist in rescue operations. This he did and then went along the P.26 intake gate passing through the ventilation doors which were closed and over the air bridge, where he noted that both access holes were open. Sometime later Best, acting on instructions, propped open the ventilation doors.

The overman, deputy and a number of men who had been in the intake and survived the explosion, attempted rescue operations while waiting for the Rescue Brigade to arrive. They realised the impossibility of going on to the face from the intake end, they went down the ladder at the air bridge into the Maindy Heading Return and along to the junction with the return gate from the face. The overman got into the return gate for about 10 yards but was persuaded to go no further. T. Rees, a rider, working in the Maindy Heading Return who had suffered serious injury was given first aid by the deputy.

The Porth Central Rescue Station was alerted at 1.05 p.m. and the Brigade arrived at the pit at 1.17 p.m. A team composed of Permanent Brigade members captained by L.C. Lewis and accompanied by the superintendent; J Perry went down the pit at 1.25 p.m. and arrived at the affected district at 2.10 p.m. They found the atmosphere smoky and dusty but it cleared slowly. Having been instructed t be back at base by 3 p.m., the team had soon to leave the face and return. Lewis then led the team into the face for second time and they reached the mid-point before turning back. There as still a great deal of dust in the atmosphere which duly cleared and the bodies were recovered.

Those who lost their lives:

- Ronald Arnold aged 48 years, deputy.

- Ernest John Breeze aged 38 years, manager.

- Ernest William Burnett aged 46 years, chargeman.

- Peter Calvert aged 40 years, repairer.

- James Channing aged 46 years, poster.

- Albert William Colcombe aged 44 years, team captain.

- Raymond John Daniels aged 34 years, stableman.

- Gerrard Wayne Davies aged 24 years, assistant unit electrical engineer.

- Kenneth Davies aged 26 years, plough operator.

- David Evans aged 28 years, poster.

- Ronald Flower aged 45 years, repairer.

- Ronald Gregson aged 28 years, electrician.

- David Alfred Griffiths aged 43 years, repairer.

- Thomas Hann aged 42 years, transfer point attendant.

- Richard William Hucker aged 32 years, poster.

- Ivor Jacobs aged 45 years, poster.

- Henry Lee aged 56 years, roadman.

- Leonard May aged 33 years, poster.

- Ivor Morgan aged 32 years, poster.

- Arthur James Mewman aged 46 years, poster.

- Vivian Nicholas aged 52 years, poster.

- Harold David Pope aged 50 years, overman.

- Donald Price aged 48 years, poster.

- Evan Luther Rees aged 55 years, repairer.

- Gwilym Thomas aged 33 years, poster.

- William Isaac Williams aged 51 years, repairer.

- Edmund William Williams aged 54 years, repairer.

- Leslie James Williams aged 54 years, undermanager.

- Sidney Williams aged 47 years, poster.

- Trevor John Williams aged 27 years, poster.

Seriously injured:

- Thomas Rees aged 62 years, rider.

The public inquiry into the causes of and the circumstances attending the explosion at the Cambrian Colliery, Glamorgan on 17th., May 1965, was conducted by H.S. Stephenson, B.Sc., M.I.Min.E, H.M. Inspector of Mines and Quarries in the Law Courts at Cardiff on 19th July 1965, and lasted for four days. All interested parties were represented and the report was presented to the Right Honourable Frederick Lee, M.P., Minister of Power on 30th. September 1965.

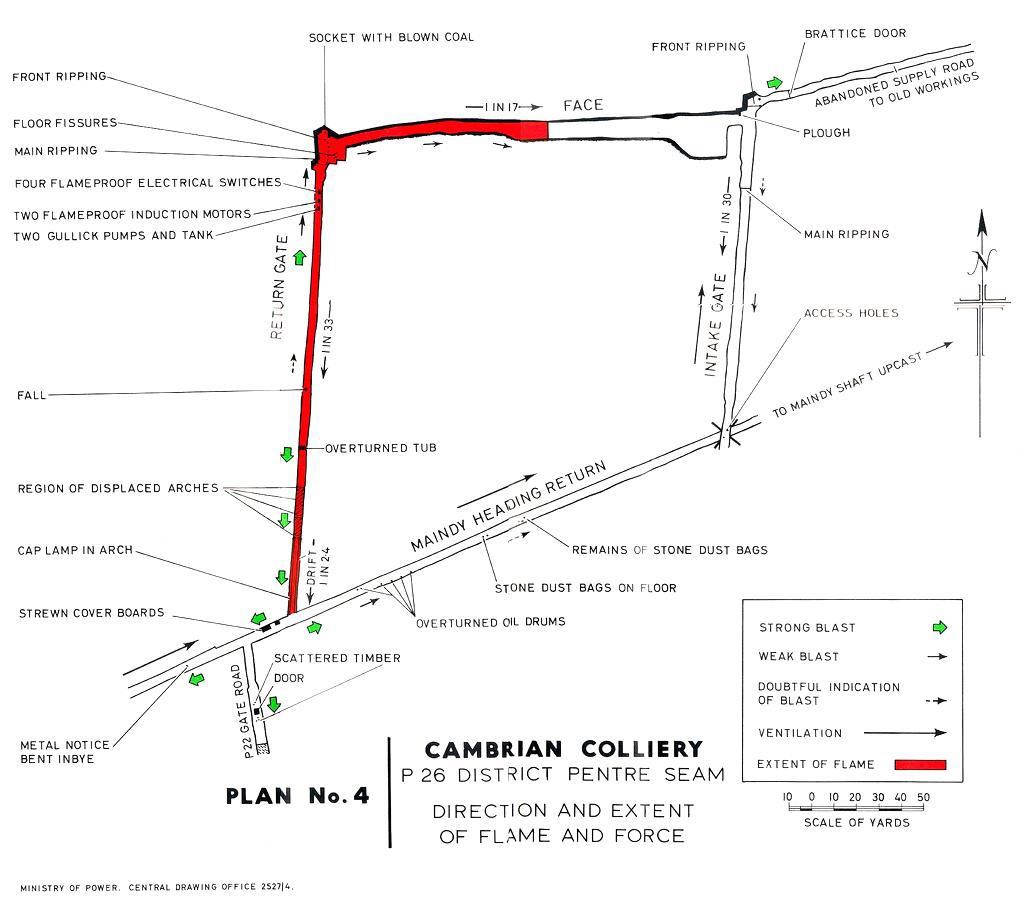

With the recovery operations, H.M. Inspectors of Mines and Quarries made a detailed investigation of the explosion area to find the cause of the disaster and from the results of the examination, it was concluded that the blast and flame had passed 325 yards along the face and associated roadway and about double this distance had been subjected to blast.

Much of the inquiry turned to the air bridge and experiments demonstrated that when the access holes in the bridge were covered, leakage occurred into the Maindy Heading Return. The Inspector commented:

Despite the air bridge leakage there was, still in my opinion, sufficient air to provide adequate ventilation for the face. But the poor construction of the air bridge and the way in which it was used were examples of deplorably bad practice, which should not have been tolerated by anyone having responsibilities for the safe working of the mine.

The evidence clearly established that, on the morning of the explosion, both access holes in the air bridge were open at the time of the explosion and had been for at least two and half hours. With such a prolonged interruption the ventilation of the district, everything points to the likelihood that by 12.55 p.m. that morning a situation very similar to that obtained by experiment had developed and that sufficient firedamp had accumulated in the return gate to sustain the ensuing explosion.

The point of ignition was at the gate end switch controlling the return end plough motor. All the evidence pointed to the fact that the two electricians were trying to locate a fault which had stopped the motor and to do this they had opened the hinged cover. Tests proved that the removal of this could cause substantial arcing. Unfortunately this occurred when there was considerable firedamp in the atmosphere.

The Inspector concluded his report with the recommendations that:

1) there should be a statutory provision requiring firedamp determinations to be made at the end of the face return roadways, as nearly as possible at the same time as the present statuary determination are made

2) a high degree of priority be accorded to the development of instruments and systems for the continuous monitoring of firedamp

3) in places where firedamp is a hazard, all gate-end switches should have integral testing facilities, but pending this every switch or bank of switches in such places and not equipped, should be provided with a test plug and

4) test instruments designed for tracing faults in control circuits external to switchgear should be developed.

REFERENCES

The report of the causes and the circumstances attending the explosion which occurred at the Cambrian Colliery, Glamorgan, on the 17th May, by H.S. Stevenson, B.Sc., M.I.Min.E., H.M. Inspector of Mines and Quarries.

Information supplied by Ian Winstanley and the Coal Mining History Resource Centre.

Return to previous page