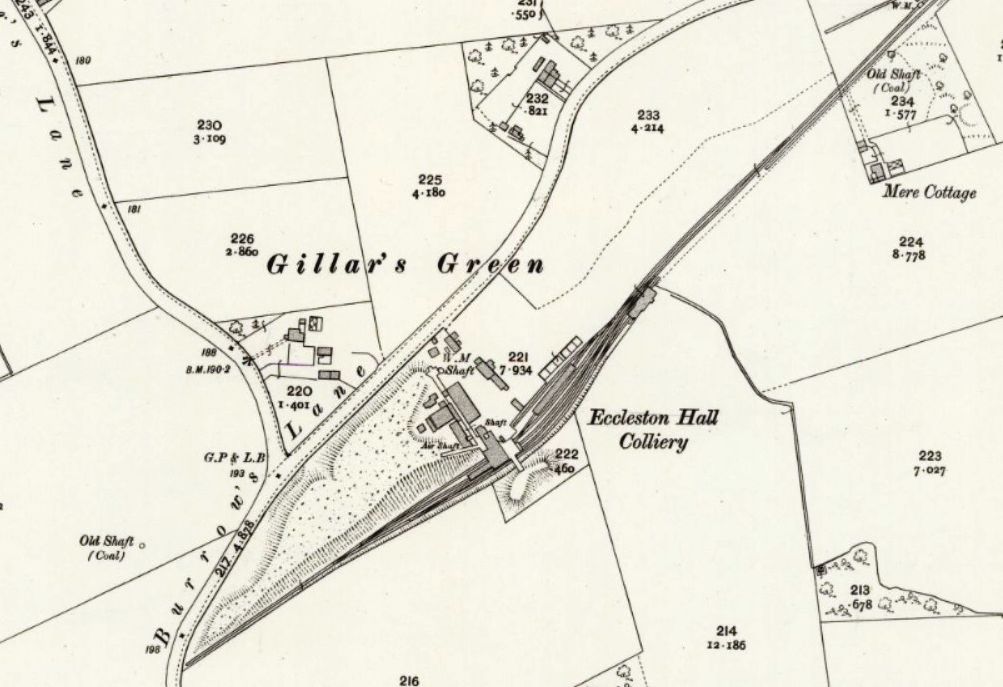

The colliery was situated on the Eccleston Hall Estate. Coal had been mined on the estate during the eighteenth century by the local squire and various lessees. A colliery is also mentioned in this area in the 1894 Inspector’s Report when it was owned by the Worsley Mesnes Colliery Co. The colliery employed about 300. The Colliery Guardian referred to several shafts already sunk on the estate by former lessees of the minerals. Two of the shafts were used by the Company to form part of their colliery. The colliery closed about 1910. The opening of a new colliery was a great event in the district since it brought the prospect of new employment. The opening could be the re-opening of the old Gillers Green Colliery which closed in the 1880s.

14th. August 1891.

Colliery Strike.

Five weeks ago the Company gave notice to eighty men that they would receive a reduction in wages from, 4/- to 2/6d. per ton. The men opposed this and the Miners’ Agent, Thomas Glover was talking to the masters on their behalf but there was no progress and the men stopped work with no prospect of a settlement.

28th. August 1891.

The strike continues with no prospect of a settlement and no steps taken to resolve the situation.

A detailed description of the colliery and the engine appeared in the Colliery Guardian on 30th. December 1892 and reproduced below. Please note that we do not have copies of the illustrations listed in the text.

ECCLESTON HALL COLLIERY

This colliery is situated 1.5 miles west of the town of St. Helens and 1.5 NE of Prescot. It is an old colliery now being reopened by the Worsley Menses Colliery co. of Wigan. The minerals are leased from Samuel Taylor whose estate adjoins the Knowsley Park estate the property of the Earl of Derby.

GEOLOGICAL

The geological features are interesting the outcrop of the New Red Sandstone lying about half a mile to the south of the shafts which are sunk entirely through the coal measures.

The Bunter series of New Red Sandstone comprises Upper Mottled sandstone, the Pebble beds, Lower Mottled Sandstone. The Pebble beds are estimated to be 600 ft thick and are largely developed in this locality the sandstone with its peculiar quartz pebbles being used much for building.

Several shafts appear to have been sunk on the Eccleston Hall estate by former lessees of the minerals. Two of these shafts have been sunk to the Main Delph have been utilised by the resent Company who on commencing their operations found them full of water to the surface. They subsequently found out after an immense volume of water had been lifted to the surface that water in the old working of the Flaggy Delf and main Delph mines had been dealt with. Besides the ordinary feeders issuing from fissured sandstone in various parts of the two shafts which are running at the resent time the water lifting operations had in fact drained all the workings to the rise of the water levels in the main delf.

The north shaft or No 1 was 9 ft in diameter to the Main Delf and 84 yards deep and has been sunk 137 yards further, the same size to the Arley or Little Delf mine. The No 2 shaft is 60 yd south of No 1 and was sunk by the former lessees 84 yd and 10 ft in diameter to the same delf. The resent Company have sunk this 137 yards further and 13 ft in diameter leaving the upper part stripped and relined at a future time.

WATER LIFTING

The main task of clearing the water from the shafts was done by the No 2 winding engine of 70 hp by means of wrought-iron barrels of 600 gallons capacity the other on No 1 shaft of 500 gallons capacity. The situation was well adapted to give the best results by this method one barrel being raised in one shaft while the other descended in the other. It is stated that in two months or more the quantity of water raised was 550 gallons per minute one barrel being raised and discharged every minute. This was supplemented afterwards by an engine and pump of the Tangy type placed on temporary bearings in each shaft being moved down in stages as the water was lowered.

The no 1 pump had one 14 in cylinder 2 ft stroke and 8 in double-acting plunger. The No 2 had a 16 in cylinder 2 ft stroke and 7 in double-acting plunger.

In deepening the shafts the main delf feeders were encountered but the principle rush of water came off when the Rushy Park old workings were reached which had been driven from a pair of shafts some distance away and sunk about sixty years ago. These workings being much less extensive than those named above were soon cleared of water. No feeders were found below the Rushy Park Mine. At the resent time No2 pump is placed in a lodge room in the Rushy Park mine and forces a small quantity of water 80 yds up to the lodge room in the Mine Delf where No 1 pump is placed permanently which forces water to the surface 80 yds through 6 in rising mains. this engine is driven at a speed of 45 revs per min delivering about 360 gallons per minute. These engines presently raise all the water that is now encountered.

The accompanying sketch shows a side view of a tank or barrel of 500 gallons capacity for raising water; the barrel being filled automatically and the lever E. When the barrel is lowered upon the running jiddy valve, A is forced upwards by the rod D. The valves are about 20 in diameter.

WINDING

The winding engines at the north of No 1 shaft have two horizontal cylinders 25 in by 38 in slide valves and an 11 ft cylindrical drum. the south or No 2 engine has two horizontal cylinders 25 in by 54 in slide valve run on rollers and there is an 11 ft drum. The engine house is placed between the shafts and serves both engines. Owing to a depth of 3 or 4 yds of drift the excavation for the foundations was heavy and the masonry of considerable depth consisted of bricks set in ordinary mortar and cement. The sidewalls of the house are of 14 in brickwork

HAULING

An engine placed on the surface has been adapted for underground haulage. It has two horizontal cylinders 24 in diameter and a 2 ft stroke. The reversing gear is moved by means of a large hand wheel and a pair of cogwheels.

BOILERS

Two Lancashire boilers 30 ft by 7 ft supply the steam at a pressure of 70 lbs to all the engines including the pumping engines of the shaft. There are four cross tubes in each flue the boilers are fed with an injector with live steam.

The headgear of the No 2 shaft is 60 ft above the ground and the pit bank is 22 ft above the surface which gives ample height for the screening arrangements.

SCREENS

The accompanying diagrams show the views of the screens at the colliery Fig 1 shows a which is a large coal screen fixed with steel bars the coal falls on a travelling steel band B 30 ft long and 4 ft wide the plates are 6 ft wide upon this band the coal is cleared if impurities and is then delivered to a second screen separating the nuts which they fall into a hopper at N. At D a rising and falling shoot is provided. The slack hopper is at H. There is a door or stop at which passes the coal through in regulated quantities. It is often seen that the coal falls on the travelling bands in heaps in which form it is impossible to clear out foreign matter properly. Fig 2 the large coal is treated on the jigging screen J made of a wire network 40 sq. ft in area vibrated lengthways it is then delivered to the steel travelling band 30 ft by 40 ft from whence it passes through the shoot s into the trucks. This shoot had a movable end. The small coal then goes through the screen J drops on the plate P which coveys it to the head of another jigging screen K with a reverse inclination. The area of the wirework is 24 sq. ft. the nuts pass over the screen in to the trucks at T and the slack which passes thorough fall into a hopper upon the conveyor G which carries to the tricks on a separate line of rails.

OS Map, Lancashire CVII.3 1906

Reproduced by permission of the National Library of Scotland