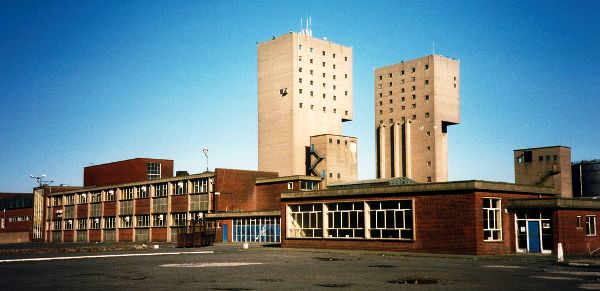

Parkside Colliery 2008

Used with kind permission of Frazerweb

When borings proved about 100 million tons of coal reserves in six seams near Newton-Le-Willows, the National Coal Board decided to sink a new colliery. It chose the civil engineers, Kinnear-Moodie working with a South African sinking contractor, who provided a sinking Manager and a nucleus of skilled men. The latter were skilled in sinking deep shafts quickly.

The foundation stone for Parkside Colliery was laid in May 1957, and sinking in No.1 Shaft began on November 24th and at No.2 Shaft on December 1st. During the first six months the contractors made slower than expected progress, but then reached an average rate of 57 metres per month. The target of 76 metres per month was achieved and exceeded when a UK sinking speed of 94 metres of completed shaft was hit in September 1958. The two 7.3 metre diameter shafts reach their final depth, of around 812 metres, in 1962. The £13 million colliery began producing coal from two faces in the Crombouke Seam on 31st March 1964. Faces in the Lower Florida quickly followed. All faces were equipped with the latest power loading machinery and powered roof supports. The first face in the Wigan Five Feet seam got away in mid-1985.

Both shafts had massive Koepe winding towers built over them. One was 58.4 metre high and the other 62.6 metres. No.1 Shaft wound men and materials while coal was wound in 15-tonne skips at No.2 Shaft. Other surface installations included a coal preparation plant, twin ventilation fans and an electricity sub-station. The waste and dirt cleaned from the coal used to fill an old quarry alongside the M6 motorway. A scheme to reorganise the coal preparation plant in 1977 cost £750,000 and both improved the product and reduced maintenance costs.

Like other collieries in the area, methane drainage at Parkside produced significant amounts of methane. Some of it was burnt in the colliery’s boilers, but any surplus gas was exhausted to the atmosphere. In August 1978, therefore, the NCB contracted with Joseph Crosfield & Sons Ltd, chemical manufacturers, of Bank Quay, Warrington, to supply methane from Parkside to that company’s boilers. In May 1980 they were linked by a 12.23 km long pipeline which initially carried 9.5 million therms of gas per year. That amount was raised to between 12 and 15 million therms per year from June 1983.

About 60 per cent of Parkside’s output went to power stations, especially Fiddlers Ferry Power Station, near Widnes. The “merry go round” rapid loading bunker, installed in 1976, was improved in 1985 at a cost of around £500,000. This loaded a train of continuously coupled air-braked steel hopper wagons, each with a capacity of 30 tons, to be loaded with, or unloaded of, 1,000 tons of coal in less than half an hour.

Like practically all of the British Coal Corporation collieries Parkside could not produce coal cheaply enough to be competitive and it closed in June 1993. It was the last pit in the Lancashire Coalfield

Seams worked at Parkside:

| 1965-1985 | Lower Florida |

| 1965-1970, 1985 | Crombouke |

| 1975-1980, 1990 | Ince Six Feet |

| 1980-1990 | Wigan Four Feet |

| 1985 | Trencherbone |

| 1985 | Wigan Five Feet |

| Coal produced (tons) |

Output/manshift (cwts) |

Manpower | |

|---|---|---|---|

| 1957 | — | — | — |

| 1958 | — | — | 12 |

| 1959 | — | — | 47 |

| 1960 | — | — | 101 |

| 1961 | — | — | 184 |

| 1962 | 2,019 | — | 286 |

| 1963/64 | 22,747 | — | 451 |

| 1964/65 | 243,270 | 28.7 | 987 |

| 1965/66 | 353,828 | 30.2 | 1,192 |

| 1966/67 | 433,329 | 29.6 | 1,377 |

| 1967/68 | 580,000 | 35.5 | 1,534 |

| 1968/69 | 636,475 | 38.7 | 1,550 |

| 1969/70 | 650,097 | 37.7 | 1,573 |

| 1970/71 | 589.845 | 33.3 | 1,648 |

| 1971/72 | 488,847 | 29.58 | 1,753 |

| 1972/73 | 739,000 | 39.5 | 1,738 |

| 1973/74 | 516,978 | 33.3 | 1,683 |

| 1974/75 | 693,318 | 39.5 | 1,662 |

| 1975/76 | 761,672 | 44.4 | 1,653 |

| 1976/77 | 599,173 | 35.6 | 1,652 |

| 1977/78 | 611,769 | 36.5 | 1,686 |

| 1978/79 | 810,137 | 46.06 | 1,718 |

| 1979/80 | 831,527 |

Plan of the workings. Copyright © Lee Reynolds as used here with his permission

Further information:

- NMRS Records, Gazetteer of British Collieries.

- Parkside Profile (May 2015)

- Coalmine Pro Boards – Shaft Sinking at Parkside Colliery (May 2015)