| COLLIERY | BAMFURLONG | ||||||

|---|---|---|---|---|---|---|---|

| LOCATION | Immediately South of the Leigh Arm of the Leeds & Liverpool Canal and west of the LNWR Warrington – Wigan line. (the West Coast Main Line) | ||||||

| OWNERS |

|

||||||

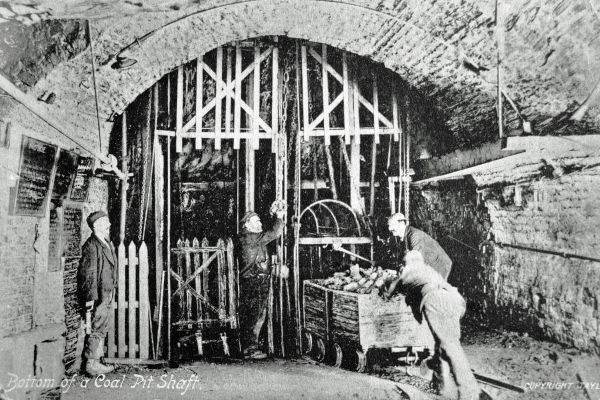

Bamfurlong Colliery 1905 – Wigan pit bottom

The onsetter is raising the shaft gate, a deputy waits to go up on the left. Used with kind permission of Pitheadgear

Shafts

Nos. 1 & 2 Pits, old shafts five feet diameter, enlarged by Cross, Tetley to 12 feet diameter. Sunk to 220 yards. No.2 the upcast shaft.

Nos. 3 & 4 Pits, commenced c.1873. No.3 Pit 15 feet diameter, No.4 Pit 16 feet diameter. Both shafts intended to be 18 feet finished diameter. Four rings of cast iron tubbing inserted to withstand pressure from quicksand. Nos. 3 & 4 shafts sunk initially to Wigan Nine Feet Mine with future deepening to Arley Mine.

Winding (1896)

No.1 Pit, – Twin cylinder horizontal engine 25 inches x 48 inches, slide valves, parallel drum 13 feet diameter, brake path each side. Double deck cages, one tub per deck. Winding ropes 11/8 inches diameter, 3 wire rope conductors per cage, headgear 60 feet high with 14 feet diameter pulleys. Winding ropes fitted with Ormerod detaching hooks.

No.2 Pit – Ventilation and emergency exit only. Single cylinder winding engine 20 inches x 48 inches.

No.3 Pit – Twin cylinder horizontal engine, Robert Daglish & Co., St Helens, 1881. 32 inches x 72 inches, Cornish valves, cast iron drum in three sections each with 8 arms. Four tubs raised in each cage, two tubs per deck. Three wire rope conductors to each cage. Headgear 61 feet high with 12 feet diameter pulleys. Ormerod detaching hooks.

No.4 Pit – Twin cylinder horizontal winding engine 36 inches x 72 inches, Cornish valves, slightly conical drum 21 feet diameter, cast iron in three sections, eight arms per section. Oak lagging 7 inches thick. Two brake paths. Six 8½ cwt tubs raised, two tubs per cage deck. Winding ropes 1½ inches diameter fitted with Ormerod detaching hooks. Headgear as No.3 Pit.

Underground Haulage

Six haulage engines located underground operating direct rope, main and tail and endless rope haulages plus two self-acting endless rope haulages. All endless rope haulages on over-rope system.

Compressed Air

Single air compressor 16 inches (steam), 20 inches (air) x 29 inches stroke and single air compressor 13 inches (steam), 15 inches (air) x 24 inches stroke, supplying three haulage engines and two underground pumps.

Air compressor rebuilt from an existing 24 inches x 42 inches engine by Walker Bros., 1911, Works No.16376. New air cylinder 26 inches x 42 inches steam 80psi., air 60psi.

Pumping

One Cameron pump and one Tangye pump, compressed air operated, located inbye and pumping to No.3 Pit. Water wound at night in tanks.

Electricity

Electric light set located underground for Nos. 3 & 4 Pits pit-bottom lighting. Peter Brotherhood three-cylinder engine, 200rpm., belt drive to 1400rpm. direct current generator, 45amps. at 110 volts.

Ventilation (1896)

Nos. 1 & 2 Pits – furnace at No.2 Pit, 120,000cfm.

Nos. 3 & 4 Pits – two furnaces at No.4 Pit, combined output 250,000cfm at 2½ inches wg.

1908 – Walker Bros. “Indestructible” fan installed, 24 feet diameter pulley 8 feet 6 inches diameter, 15 – 1¾ inches ropes. Corliss valve engine, Dobson valve gear, 18 feet diameter flywheel.

Boilers (1896)

Nos. 1 & 2 Pits – two Lancashire 7 feet x 30 feet, three Cornish 5 feet 6 inches x 30 feet Working pressure 50psi.

Nos. 3 & 4 Pits – eight Lancashire boilers 7 feet x 30 feet, 60psi., fitted with Meldrum’s forced draught furnaces.

Seams Worked (1896)

Pemberton Two Feet, Pemberton Four Feet, Wigan Five Feet, Wigan Four Feet and Cannel.

Accidents & Disasters

On 14th January 1892 a fire in the engine house caused smoke to enter the workings. Many miners managed to escape through the air doors into the clean return airway, but 16 failed to do so and suffocated. The fire was caused by an accident with a paraffin lamp; the lad in charge of the engine was ill that day and a 13 & 15 year old were sent to take his place. The full report can be found here.

CLOSURE – 1936.

Wigan Coal Corporation worked shaft pillars 1934 to closure. (Thereafter the colliery would be useful for it’s output quota transferred to other collieries).

NOTES

Walker Bros. supplied two air cylinders 26 inches x 48 inches complete with bedplates (Works No.13503, 23-7-07) to Cross, Tetley. Colliery not stated. Could be Bamfurlong or Mains.

Copyright © NMRS Records: G. Hayes Collection

Return to previous page