Newbridge (ST 2147 9598)

Newbridge (ST 2147 9598)

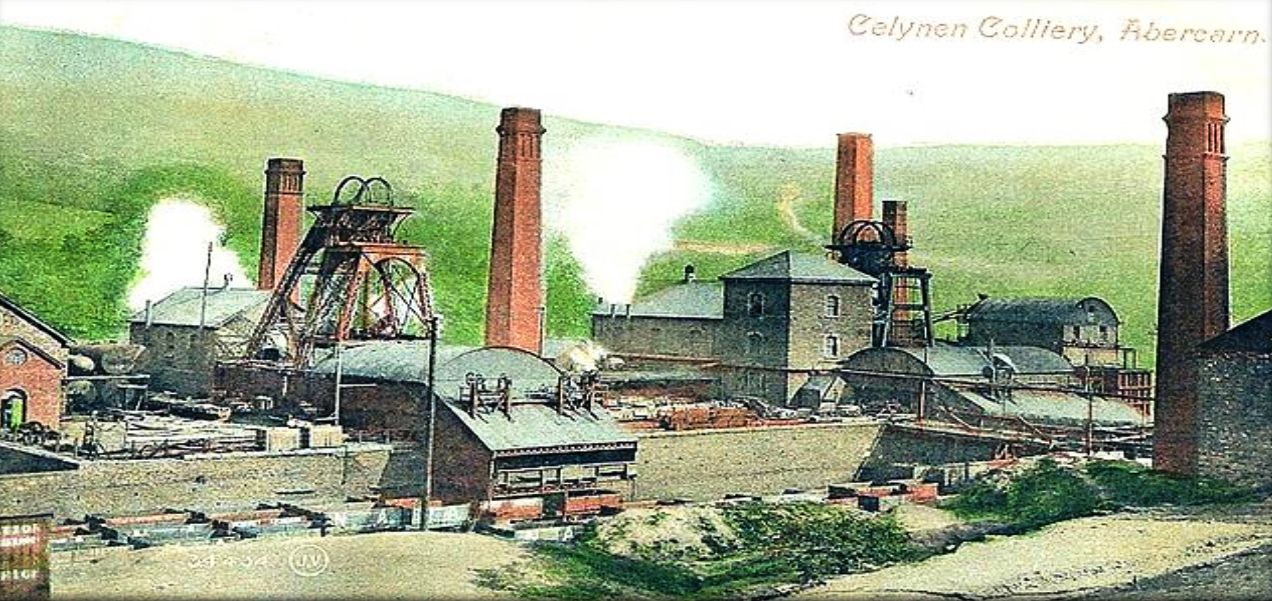

The first sod for the sinking of this colliery was cut by Mrs. Thomas Beynon on the 27th of May 1873 the first tram of coal was raised on August 16th 1876. The Black Vein seam had already proved an enormous success at Abercarn to the south and had been worked successfully for over twenty years to the east from the Cwmbran Drift. The profitable results from both of these collieries must have been the basis for the engineer’s report and the decision to sink at that particular site. Three shafts were sunk, with the headgear being made of iron but in the style of the old wooden types, they were built by E. Finch and Company Limited, Iron Founders of Chepstow in 1877.

The No.1 Pit was sunk to the Nine-Feet (Black Vein) seam, and the Nos.2 and 3 Pits to the Five-Feet/Gellideg (Old Coal) seam. The Nos.1 and 3 Pits were the downcast ventilation shafts and were also used for transporting men and materials and for raising coal. The No.2 Pit was the upcast ventilation shaft and was solely used for ventilation. The No.1 Pit was 357 yards deep and elliptical in shape, measuring 18 feet by 22 feet. The carriages ran on rigid guides and were large enough to accommodate two trams per wind or twenty-four men.

Winding time was approximately one minute the steam winding engine was made by Robey of Lincoln and had 30-inch cylinders with a five-foot stroke. It was powered by six boilers and was replaced in 1972 by a 1,600 h.p electric winding engine which had an hourly winding rate of 180 tonnes.

The No.2 Pit was 401 yards deep with a shaft diameter of 18 feet. A fan drift linked No.2 Pit to two fan engines; the North Fan and the South Fan which were Waddle type fans of 45 feet diameter, they were powered by three boilers. Each gave out 250,000 cubic feet of air per minute.

The No.3 Pit was 410 yards deep and elliptical in shape measuring 16 feet by 12 feet. The Carriages were large enough to accommodate one tram per wind or twelve men and run on rope guides. The steam winder was made by Fullerton, Hodgert and Barclay had 33-inch cylinders with a five-foot stroke and a sixteen feet diameter drum. It was powered by three boilers and was replaced in 1972 by a 350 h.p electric winder. The three pits were connected by landings on the No.1 Rhondda seam level with a pumping station (Lodge Room) installed alongside the No.1 Pit.

The No.3 Pit was 410 yards deep and elliptical in shape measuring 16 feet by 12 feet. The Carriages were large enough to accommodate one tram per wind or twelve men and run on rope guides. The steam winder was made by Fullerton, Hodgert and Barclay had 33-inch cylinders with a five-foot stroke and a sixteen feet diameter drum. It was powered by three boilers and was replaced in 1972 by a 350 h.p electric winder. The three pits were connected by landings on the No.1 Rhondda seam level with a pumping station (Lodge Room) installed alongside the No.1 Pit.

The colliery was opened up on two coaling shifts, the nightshift being used for repairs and maintenance, with horses hauling the trains to the main roadways where compressed air (blast) haulages would pull the loaded trains to pit bottom and the empty trains and supplies back inbye. Due to the gaseous nature of the Black Vein seam, no naked lights were permitted with Mueseler and Davy safety lamps in use.

Faced with apparent limitless reserves in a 10-foot thick seam, and difficulties in extracting the whole seam, and of finding enough rubbish to stow to gobs around 4 feet at the top of the seam was left behind except in the roadways where total extraction occurred. The colliers were only paid for large lump coal so all small coal produced was stowed in the gobs:

There are 110 working places, and as there is a distance of twelve yards between each of these, walking around the face is similar to walking by the side of a wall of coal 7 feet thick for an uninterrupted distance of three-quarters of a mile, meeting two men busy at work in each roadway. The coal worked by these men is first taken by horse haulage a short distance, to a point on the main road, technically called the ‘double parting’ which is over two and a half miles from the pit bottom. At this point, it is taken by main and tail rope haulage in journeys of 25 to 30 trams a distance of about half a mile, when it is attached in like manner to an endless rope haulage which conveys it nearly two miles to pit bottom. The regularity with which the full journeys arrive at pit bottom every twenty minutes indicates a high level of efficiency. This haulage level is laid with three lines of rail throughout its distance, having double roads at meeting places, and is absolutely straight.

A washery was constructed at this colliery in 1888; it was replaced by a newer model in 1909.

In February of 1921, another Worldwide trade depression affected the Coalfield particularly badly with 80,000 miners being laid off. More than any other area of the UK the south Wales Coalfield depended on the export trade, the first decline in this trade was in 1921, there was a revival in 1923 due to a strike of miners in the USA, but the times were changing, oil was rapidly replacing coal in the ships and railways of the World, the Versailles Reparation Treaty replaced some markets with German coal, and other European nations such as Poland were subsidising the coal exports in order to gain currency.

The Prince of Wales Colliery at Abercarn was closed in 1931 and local collieries were laying off up to a third of their workforce. Celynen South Colliery suffered the same as the rest of the Coalfield and temporary closure came in June 1930.

In May 1932 the pit was re-opened due to an order of 240,000 tons of coal for the Egyptian State Railways but closed when the contract was completed. The No.1 Pit only was opened again in April 1933, due to another order from the Egyptian State Railway and one from the Italian State Railways.

In 1935 the colliery operated 79 coke ovens of the beehive type producing a brand of coke called Newport Abercarn Furnace and Foundry Coke, with 1,700 men employed underground and 230 men on the surface producing with the Celynen North Colliery 950,000 tons of coal in that year.

At Nationalisation in 1947, Celynen South Colliery became part of the No.6 (Monmouthshire) Area. The National Coal Board Agent for the Colliery was J.H. Austin, the Manager, H.L Nash, and the Under Manager, WE. Lewis. There were by the end of that year 974 men employed at the Colliery, with 785 working underground and 189 on the surface. Work was being carried out in the Three-Quarter (Lower Six-Feet), Riled (Four-Feet), Meadow Vein (Yard/ Seven-Feet), and Big Vein (Upper Six-Feet) seams, with re-workings being earned out in the Black Vein (Nine-Feet) seam. For the week-ending the 24th of February 1947 actual output of coal was 5,323 tons, the effective number of men employed was 898, with the number of shifts lost through absence being 850.

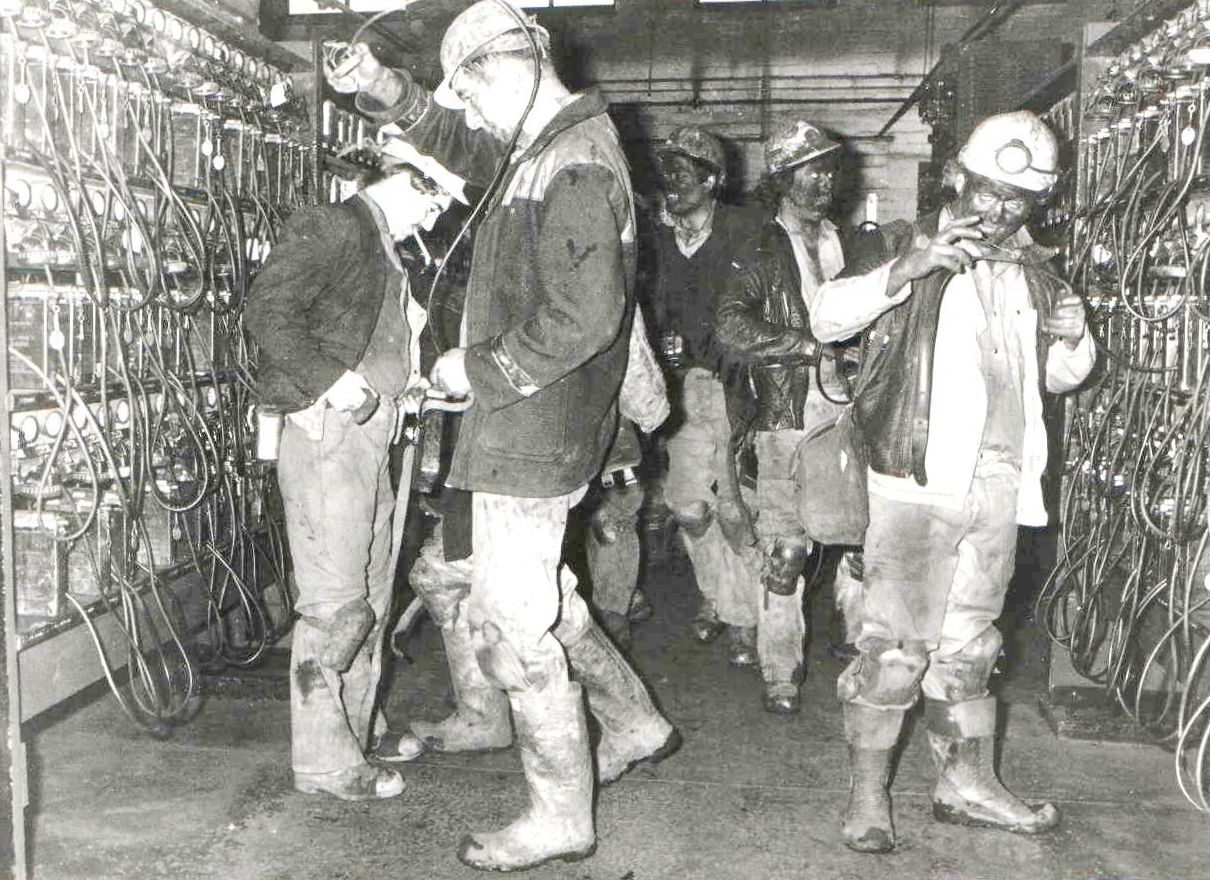

Along with the current policy of the 1940s, the NCB decided to modernise the surface of the colliery, the old coke ovens were demolished and in December 1949 it was agreed to carry out the following improvements: Boiler plant re-organisation at a cost of £19,000. New pay office at a cost of £480. A new canteen at a cost £2,935 New lamp room at a cost of £5,000. The Baths were first used on the nightshift of Sunday, the 14th of March 1954.

The lamproom at the end of the shift

The ‘South entered a little ‘Golden Period’ in the 1950s; the pit broke its own annual output record, post nationalisation, by raising 377,552 tons of coal as compared with the previous year’s output of 361,690 tons of coal. On November the 8th 1957, it raised 1,844 tons in a day beating the old record of 1,825 tons of coal.

In 1951 the Colliery was working the L and P coalfaces in the Big Vein (Upper-Six-Feet) seam and West Black Vein District from No.1 Pit, and the R and S Conveyors (coalfaces) in the East Meadow Vein District from No.3 Pit. Output from each coalface was approximately 150 tonnes a day with a colliers’ helper on R Conveyor receiving a wage of £8.6/9d a week.

The West Meadow Vein District in No.3 Pit was opened in 1952 and by 1954 annual output of coal from the Colliery was 217,083 tons. In 1956 output had risen slightly to 222,548 tons with 409 men employed on the coalfaces and 988 men employed at the Colliery in total. By the start of the next decade in 1960 output had dropped to 201,000 tons with 867 men employed at the Colliery.

The 1960s was a difficult decade for the mining industry, intense competition from oil as a source of power greatly reduced the markets for coal, and a new realism caused by economic problems with the Government brought about a change in attitude by all political parties towards the subsidising of Britain’s Coal Mines. Lord Alf Robins was brought in as Chairman of the National Coal Board and a massive bout of colliery closures took place. In the South Wales Coalfield, alone manpower dropped from 90,937 in 1960 to 36,236 by 1970 with 70 pits being closed. Probably the only reason that the Celynen South Colliery survived in the early sixties was due to the high-quality prime coking coal it produced that was vital in the supplying of Llanwern Steelworks. If the Colliery had been in the power station market it would have been goodbye to Celynen South. However partial closure did occur when the National Coal Board closed the No.3 Pit and used the manpower to fill the vacancies in the No.1 Pit. The No.1 Pit was now firmly entrenched in the west-side Upper-Six-Feet (Big Vein) seam where fifteen districts prefixed B1 to B15 were worked. The early coalfaces were worked by ploughs attached to armoured conveyors with roof supports being hydraulic posts and rigid steel bars. Self-advancing supports were tried in the Bl0 coalface in June 1967 but the ‘chocs’ kept sinking into the soft floor and advances were down to an average of 0.45 metres per shift by April 1968, the ‘chocs’ were withdrawn in February 1968 and the Big Vein reverted to post and bars for roof supports.

With the closure of No.3 Pit, headings were driven into the Black Vein (Nine-Feet) seam pillars near the pit bottom in an attempt to boost output. Six Samson gathering arm loaders were installed in narrow headings with an expected output of 250 tons a day. In 1966 a Lee Norse Continuous Miner was installed in this seam at a cost of £50,000. It was capable of advancing 31metres per week. In February of 1968, it was decided that there would be no further development in the Black Vein and only retreat work would be carried out for the next two years. Around this time the Celynen South became known as the umbrella pit because it was always opening and closing. The geology was difficult, mechanical and electrical breakdowns frequent, and absenteeism was high, morale low and productivity rapidly declining. In March of 1968 the colliery was placed on the NCB’s jeopardy (closure) list and given three months to turn the colliery around.

A massive effort by all parties, management, unions and men, managed to turn the colliery around and in September 1969 it was taken off the closure list, the first colliery in the South Wales Coalfield to do so.

The 1970s got off to an entirely different start than the previous decade, the oil sheikhs had flexed their muscles and the price of oil had rocketed, coal was once again at a premium. In 1969 the miners were near the bottom of the wages league, an unofficial strike in 1970, and official strikes in 1972 and 1974 had rocketed them to near the top of the wages league. A Labour Government was elected in the wake of the 1974 strike and the pressure to close collieries was eased, in fact, the reverse was now the policy and investment started to come into the industry.

At the Celynen South Colliery, the steam winders were replaced by electric ones during the holidays of 1971 at a cost of £176,000, and a complex underground storage bunker was installed at pit bottom in 1972 at a cost of £90,000. In 1974 the colliery withdrew from the west side of the pit and the Big Vein and turned towards the Meadow Vein (Yard/Seven-Feet) seam on the east side of the pit not far from the drivage that was sent up from the Old Coal seam in 1964. Output per man shift at the colliery was now down to 9 hundredweight when the Meadow Vein Ml coalface was opened, this was the first face at the colliery to cut coal by a ranging drum shearer, with advance headings either side of the coalface and on this coalface alone output per man shift soon rose to 18.2 hundredweights.

Another coalface was ready to open in 1974, the M3, but it was delayed until February 1975 by waiting for self-advancing roof supports to be supplied. In July 1974 the NCB invested in a new surface layout to convey coal from the pit top to the screens and coupled with the underground bunker system eliminated any delays incurred at the coalface caused by stoppages outbye.

In 1981 the colliery was working the M4 coalface (closed March 1981) at a section of; coal 94cm, dirt. 58cm, coal 114cm. The M7 coalface (started May 1981) at a section of, coal 109cm, dirt 43cm, coal 117. M6 coalface (closed June 1981) at a section of, coal 111cm, dirt 40cm. M8 coalface (started July 1981) at a section of, coal 110cm, dirt 42cm, coal 115cm. Manpower was now down to 482 men, with 120 men working on the coalfaces, 85 on development and repairs, 135 elsewhere below ground and 85 on the surface. Output was at 2,000 tonnes of coal per week. By 1983 losses were back up to £29 per tonne with the overall loss for the year being £3,168,000, the NUM Lodge embarked on a series of industrial actions which resulted in a limited recruitment campaign.

In 1985 with perverse logic, and the power brought about by defeating the miners in the 1984/85 strike, the NCB denied that they were closing the colliery, but stated that no more coalfaces would be developed after the BL1 coalface, which of course amounted to closure. The BL1 coalface was opened in November 1983 in the Black Vein (Nine-Feet) seam above the current Meadow Vein workings and in the old barrier left between the Celynen South, Abercarn and Cwmbran workings. 2.15 metres of the 3.7 metre seam was extracted on a coalface 170 metres long, it was equipped with two ranging drum shearers with roof supports of the self-advancing type. Output per man shift on the coalface reached 23.67 tonnes and overall for the colliery 4.04 tonnes with a profit of £14,500,000 made in the last six months of the colliery’s life with output standing at 7,000 tonnes of coal a week with 5,000 tonnes of that going to Llanwern Steelworks.

The Minutes of the South Wales Area Consultative Committee Meeting of the 17th of June 1985 stated “The Colliery (South) now had the highest producing face in the Area at some 7,000 tonnes per week at an oms of 3.38 tonnes. The pit had now made more than £400,000 profit in each of the first two months of the year. ..and the results demonstrate what could be done in South Wales with a good seam and favourable geology.”

As the last manager of the Celynen South Colliery, Glyn Payne said at the time, “The Celynen South Colliery is inferior to no pit.”

The BL1 District and the colliery were closed in September 1985.

SOME MANPOWER AND OUTPUT STATISTICS

- 1896: Manpower: 1,600.

- 1899: Manpower: 1,552.

- 1900: Manpower: 1,550.

- 1901: Manpower: 1,760.

- 1902: Manpower: 1,690.

- 1903: Manpower: 1,770.

- 1905: Manpower: 1,740.

- 1907: Manpower: 1,750.

- 1908: Manpower: 1,780.

- 1909: Manpower: 1,760.

- 1910: Manpower: 1,650.

- 1911: Manpower: 1,649.

- 1912: Manpower: 1,601.

- 1913: Manpower: 1,670.

- 1915/6: Manpower: 1,500.

- 1918: Manpower: 1,385.

- 1919: Manpower: 1,400.

- 1920: Manpower: 1,600.

- 1923: Manpower: 1,652.

- 1924: Manpower: 1,751.

- 1926: Manpower: 1,270.

- 1927: Manpower: 1,500.

- 1928: Manpower: 1,893.

- 1930: Manpower: 1,800.

- 1932: Manpower: 1,500.

- 1933: Manpower: 1,236.

- 1934: Manpower: 1,061.

- 1935: Manpower: 1,930.

- 1937: Manpower: 1,527.

- 1938: Manpower: 1,518.

- 1940/2: Manpower: 1,440.

- 1944: Manpower: 1,090.

- 1945: Manpower: 1,029.

- 1947: Manpower: 974.

- 1948: Manpower: 1,057. Output: 292,000 tons.

- 1949: Manpower: 902. Output: 275,000 tons.

- 1950: Manpower: 1,051.

- 1953: Manpower: 923. Output: 265,000 tons.

- 1954: Output: 217,083 tons.

- 1955: Manpower: 937. Output: 206,663 tons.

- 1956: Manpower: 994. Output: 222,548 tons.

- 1957: Manpower: 1,010. Output: 218,620 tons.

- 1958: Manpower: 998. Output: 206,882 tons.

- 1960: Manpower: 867. Output: 201,000 tons.

- 1961: Manpower: 848. Output: 176,800 tons.

- 1962: Manpower: 851.

- 1964: Manpower: 811.

- 1965: Manpower: 753. Output: 176,000 tons.

- 1967: Manpower: 709. Output: 165,000 tons.

- 1969: Manpower: 708. Output: 217,000 tons.

- 1970: Manpower: 691.

- 1971: Manpower: 656.

- 1972: Manpower: 654.

- 1979: Manpower: 568. Output: 135,000 tons.

- 1980: Manpower: 509. Output: 107,668 tons.

- 1981: Manpower: 433.

- 1983: Manpower: 513.

- 1985: Manpower: 477.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page