Newbridge (ST 2126 9743)

The Celynen North Colliery was a result of the huge success of its sister pit just down the road, the Celynen South Colliery. The ‘South had already been working forty-odd years when the decision to sink the Celynen North was made. Sinking commenced when the South Wales Coalfield was at its zenith – 1913 – with the Graig Fawr pit following in 1924. Both pits then suffered the lay-offs and short-time workings that blighted the 1920s and 1930s.

Following the success of the Celynen Nos. 1 & 3 Collieries (Celynen South), the Newport Abercarn Black Vein Steam Coal Company Limited decided to sink another pit to work the northern section of their mineral take.

In 1910 negotiations commenced leasing the mineral under the ground between Newbridge and Crumlin from the Llanover Estate with the sinking of the North Pit starting in 1913. A capital of £325,000 was raised to finance the venture. 1,000 acres of mineral rights were acquired to the north of the Celynen (South) Colliery which made a total of 4,000 acres held by the NA Company.

On the 9th of May, 1914, William Tedstone, aged 32 years, and a pumps man was suffocated in a pump lodge room, 75 yards from the surface, in a sinking shaft, owing to a steam joint “blowing” right into it from a 3-inch column of pipes fixed in the shaft. The steam was under 160 lb. per square inch pressure. The lodge room was a small one – about 12 feet square – with only one connection into the shaft. In August 1915 the manager tried to sack a master haulier so all 300 men went out on strike in probably the first strike of many at this colliery. The manager at that time was the Celynen South manager, J.M. Wallace. The Celynen South manager still controlled both mines in 1918 when he was D.A. Jones. The manager in 1923 was Thomas Arthur Rogers and in 1927 it was Robert Rutherford. The pit-bottom for this shaft was developed from the Celynen South Colliery which was a mile further down the valley, with the Celynen South No.2 Pit serving as the ventilation upcast shaft for the Celynen North until the North’s South Pit was sunk.

An extensive write-up on the Company appeared in the South Wales Shipping Annual of 1916:

The site of the new (Celynen North) Colliery is about a mile distant from the old Celynen Colliery and is separated from it by a big down-throw fault. The first shaft, 21 ft in the clear, has been sunk to the Black Vein, and in the course of the sinking a feeder was encountered at a depth of 53 yards yielding 7,000 gallons per hour. Another was met at a depth of 59 yards producing 9,000 gallons per hour, a third at a depth of 110 yards producing 20,000 gallons per hour, and a fourth at a distance of 287 yards yielding 1,000 gallons per hour. Below this only small pockets of water have been struck in thin beds of rock. The pumping was done by various types in stages, and in the permanent pump-house duplicated Sulzer pumps are being installed, each capable of yielding 91,000 gallons per hour against a head of 1,350 feet.

The head-frame is of the steel-girder type and is 70 ft high to the centre of the sheaves. The winding-engines consist of a fine pair of high-pressure horizontal Morcom compressor of 2,750 cubic feet capacity per minute, and is driven by a Siemens’ motor of 559 h.p. double tandem compound type, and are designed to start a load of twenty tons and complete wind of 500 yards in thirty-five seconds. The reversing engine is of an improved type with steam and cataract cylinders. During developments, the old colliery will serve as the upcast, and it is anticipated that the present output of approximately 500,000 tons per annum, will be considerably increased in the near future. From its largeness, hardness and solidity, the coal is especially suited both for shipment to distant destinations and for storage. It will stand much handling transhipment etc., and it is no small advantage to the company that it possesses a coal of which the small makes excellent coke.”

The final sinking was in 1924 when the Graig Fawr shaft was sunk to the Brithdir seam to serve as the house coal pit for the Company. See separate listing for Graig Fawr Colliery.

The North shaft (downcast) was sunk to the Nine-Feet (Black Vein) seam which it reached at a depth of 467 yards in 1916, it was deepened to the Five-Feet/Gellideg (Old Coal) seam at a depth of 503 yards in 1921. Its head-frame was 70 feet high to the centre of the wheel and it could wind two trams of coal in 35 seconds.

The South shaft (upcast) was also sunk to the Five-Feet/Gellideg seam which it found at a depth of 514 yards. Both shafts had a diameter of 21 feet, and 203 men were employed during the sinking in 1913, with the first coal being raised in 1916. They encountered a considerable amount of water during sinking operations with a feeder producing 7,000 gallons per hour at 53 yards, one giving 9,000 gallons per hour at 59 yards, 20,000 gallons/hour at 110 yards and 1,000 gallons/hour at 287 yards.

In 1915 the company ordered the steam locomotive Trecelynen which operated at the colliery until the 1950s. All the output of the ‘North was sent to the Celynen South Washery for cleaning, apart from the large coal which was sold unwashed until 1969 when the output of large coal had diminished to a couple of wagon loads a week it was then crushed and sent to the ‘South. The markets for the coals at that time were British Bnzole, Llanwern Steel Works and GKN Cardiff.

By June 1919, the living was easy at the ‘North, prompting reports in the newspapers that the collier at this pit only had to tickle the coal and it fell into the trams for him giving him some of the highest wages in the mining industry. It was claimed that colliers were earning £950 to £1,000 a year, although one claimed that the most that he had earned in a week was just over £4, and that was for 12.25 tons of coal.

In 1932 the company built what was reputedly the largest pit-head baths in the South Wales Coalfield at this colliery. The manager at that time was still Robert Rutherford.

In 1933 the pit was working the Three-Quarter (Upper-Six-Feet), Nine-Feet (Black Vein) and Five-Feet/Gellideg (Old Coal) seams producing around 6,000 tons of coal each week. Manpower on the coalface was 1,011, others underground totalled 578, and on the surface 153. There were also 92 horses underground, the manager was W.E. Evans. Washing of the colliery’s coal was carried out at the Celynen South Colliery.

In 1934 the Newport Abercarn Company was based at the Ebbw Vale Works with the directors being the Ebbw Vale Company’s directors, i.e. Sir W. Beynon, D.H. Allan, E. Coulman, Sir Arthur L. Dickinson, Trevor L. Mort and the agent, Ben Owen. The company secretary was Richard Green. It controlled three collieries that employed 3,575 men and produced 950,000 tons of coal in that year. Also in 1934 a railway platform was constructed at the Celynen North Halt for the use of miners, trains only stopped there at shift change times. The halt was closed in 1962.

The depression in the coal trade of the time reduced manpower slightly to 1,350 underground and 180 on the surface by 1935, the pit was then producing coking and steam coals.

In 1935 the colliery came under the control of Partridge, Jones and John Paton and Company who had purchased the mining interests of the Ebbw Vale Company. The manager in 1938 was W.C. Evans and in 1943/5 it was G.H. Simpson.

In 1943 it employed 1,078 men working the Meadow Vein, Black Vein, Lower Three-quarter and Three-quarter seams and 209 men working at the surface of the mine.

Along with the Nations other major coal mines, Celynen North was Nationalised in 1947 and was placed in the National Coal Board’s South Western Divisions No.6 (Monmouthshire) Area. Abercarn Group. At that time it employed 169 men on the surface and 1.040 men underground working the Yard Seven-Feet (Meadow Vein), Three-Quarter (Upper-Six-Feet) and Five-Feet/Gellideg (Old Coal, seams with the manager being W.B. Cleaver.

The colliery’s surface was used as a site for NCB road transport and central workshops. Nationalisation did not bring the expected peaceful industrial relations as can be seen by this dispute in 1950. Due to a shortage of manpower on the ‘R’ Coalface, management tried to move men from their normal workplaces on the ‘P’ Coalface to fill the gaps. These men refused and the manager took them to Court for breach of contract, at the same time the men took the manager to Court for breach of contract. The men won their case.

In 1958 the NCB estimated that the reserves for the colliery covered approximately 1,900 acres and were:

- Big Vein: 4,302,000 tons.

- Upper Three-quarter: 4,160,000 tons.

- Lower Three-quarter: 4,253,000 tons.

- Black Vein: 840,000 tons.

- Meadow Vein: 5,546,000 tons.

- Old Coal: 6,699,000 tons.

Total 25,800,000 tons.

At that time ventilation was provided by a Sirocco type fan 120 inches in diameter with a 300 hp electric motor. It gave 200,000 cubic feet of air per minute. Pumping was by two 750 h.p. pumps each capable of throwing 60,000 gallons per hour although actual pumping up the shafts was 120,000 gallons a day.

The manager in 1969/75 was D.R. Jones, in 1976/80 it was R.J. Williamson.

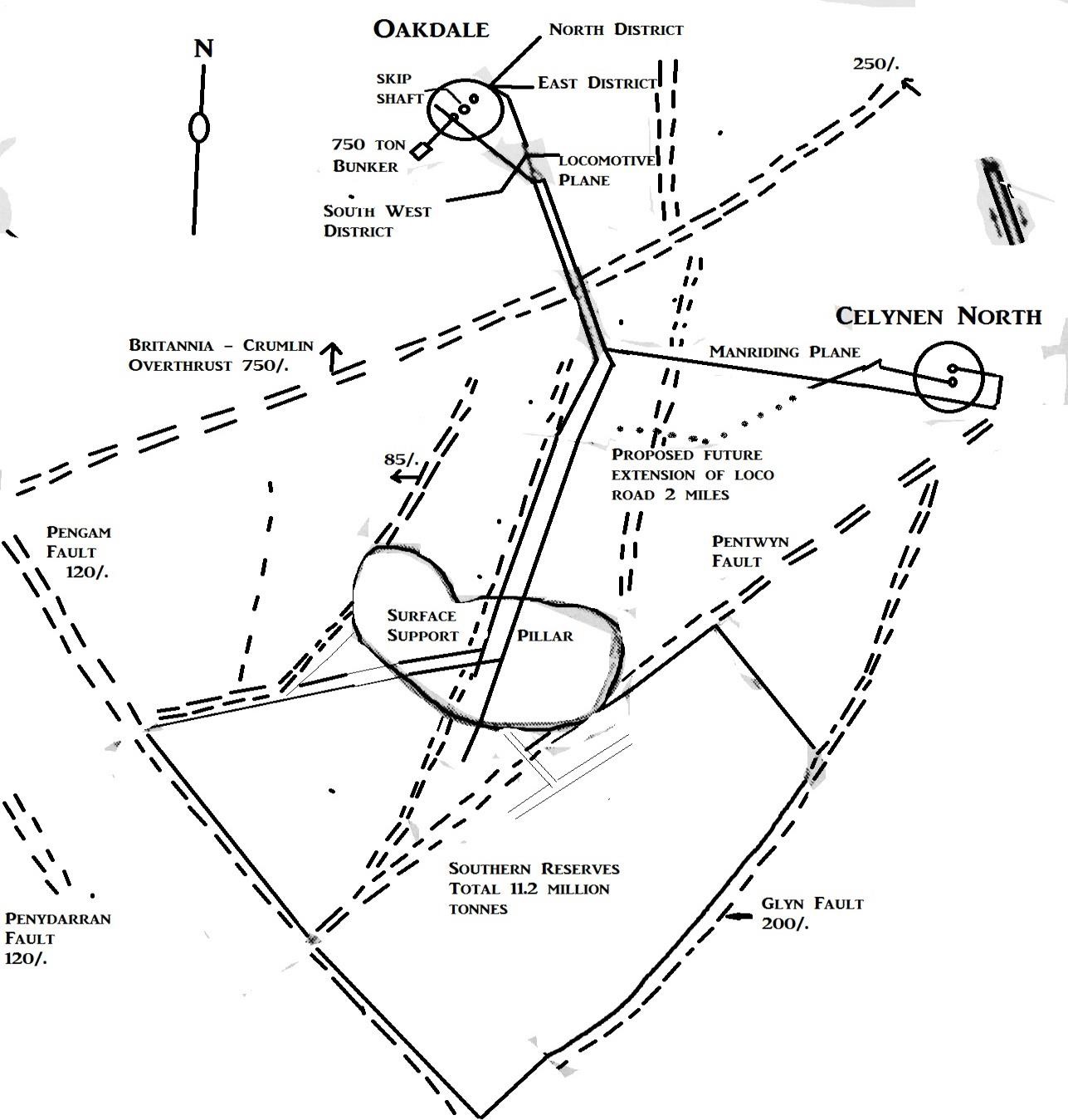

The Graig Fawr Pit was closed in 1961 followed in 1962 by the electrification of the Celynen North winding engines which cost £350,000. The coal winding engine was made by GEC and 2,100 h.p. driving a single drum of 16 feet diameter. In the 1970s this colliery’s working area was around 2.5 square miles and was bounded by the 46 metre Pentwyn Thrust geological fault to the south-east and by the 76 metre Britannia Overthrust to the north and west. There were eight miles of roadways and 2.5 miles of conveyors in use working the Six-Feet and Old Coal seams.

In 1981 the pit was working the Six-Feet seam which had an average section of between 151 and 170 cms, coalface length being between 190 and 220 metres, and the Meadow Vein which had an average section of 157 cms and a coalface length of 137 metres. All coal cutting was done by ranging drum shearers, with coalface supports being the self-advancing type. The yield of clean coal produced was 60% of total production. Manpower on the coalface was 114, on development, 190, others underground 220, and on the surface62. Output per man shift was expected to be 7.52 tonnes on the coalface, and overall 2.06 tonnes. The coalfaces in the Six-Feet seam were prefixed with the letter “S” with the S2 expected to advance at a rate of 1.53 metres per day on two coaling shifts producing a daily tonnage of 590 tonnes. In February 1981 it had a life of 829 metres. The S3 coalface was expected to start in December 1981, it had the same advance/tonnage figures as the S2. The Meadow Vein coalfaces were prefixed by the letter “M” with the M17 advancing at a rate of 1.83 metres a day on two coaling shifts and producing 475 tonnes of coal daily. It was to close in November 1981.

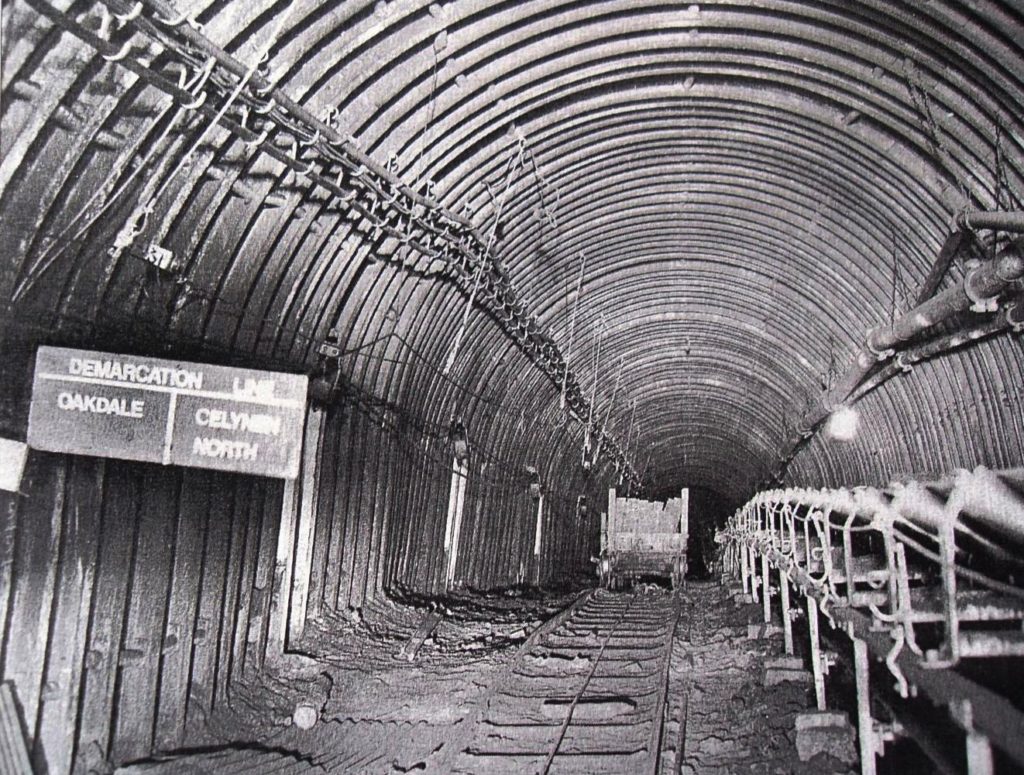

In 1982 the colliery came under the massive investment programme based at Oakdale Colliery and its coal output was diverted by underground roadway to Oakdale to become part of the largest complex in the South Wales Coalfield.

In 1982 the colliery came under the massive investment programme based at Oakdale Colliery and its coal output was diverted by underground roadway to Oakdale to become part of the largest complex in the South Wales Coalfield.

It was in the late 1970s the NCB invested an estimated £35,000,000 on a modernisation scheme, which it was aimed to; increase efficiency by a reduction in non-productive jobs, the elimination of rail tolls, and the extension of manriding underground to increase the work time at the coalface. Also, it was intended to access 11.2 million tonnes of coal to the south of Oakdale. At that time the three pits combined had total combined coal reserves of 11.4 million tonnes which would be exhausted in 10 to 13 years without major development. This, it was claimed, would give a life of twenty years at 900,000 tonnes of coal produced per year. The plan included driving 1,150 yards of roadways in one year linking Oakdale with Markham Colliery in 1979 and with the Celynen North Colliery in 1981, to make Oakdale the centre of this huge combine.

The three pits all produced 301a prime coking coals and had a combined manpower of 2,600. Skip winding was installed at Oakdale Navigation Colliery, along with computerized monitoring of coal production and conveyance plus a complete renewal of underground and surface plant. Fourteen miles of high speed 42-inch belt conveyors carried the coal production of seven coalfaces to the pit bottom where the 10.5-tonne skip brought the coal to the surface at a rate of 420 tonnes an hour (the old rate was 270 tonnes per hour) with it planned to raise 6,500 tons of coal a day at Oakdale, with a planned annual output of 887.000 tons of coal. A new inset was installed at a lower level in the north pit with a 750-tonne static bunker installed, the GEC battery locomotives were renovated after spending 25 years underground at Ogilvie Colliery. New 42 inch wide belt conveyors and Pikrose type endless rope haulages were installed to complement the three underground manriding/supplies systems with it estimated that the increased time that the men could spend at the coalface would give an extra 251 tonnes of saleable coal per day. On the surface of the mine, a new rapid loading and bunker system over the British Rail track was installed with uprated power supply to the South Pit winder plus a new land sales yard. A new tipping site had been established with a new rubbish conveyor to conveyor the dirt to the site. A new tailings plant was installed plus a new tram circuit to the North Pit and new offices, material yard and road access. On top of this the surface of Markham Colliery was demolished. In 1983 the Celynen North Colliery was losing £24.20 for every tonne of coal that it produced, and losses of -£129 for every miner employed. It had a manpower of 570 and an average production was 3,042 tonnes of coal per week.

The colliery made a remarkable recovery after the 1984/85 miners strike and obtained 120% of expected output within a month of starting back with an output per man shift of just under two tonnes. A new manager to Oakdale was installed, Desmond Caddy, who in his own words; “I admired the way she handled the strike.” He was referring to Margaret Thatcher.

The NCB report on the state of the Coalfield in April 1985 stated; “Oakdale/Celynen North: The recovery has been very satisfactory with more than 120% of normal recovery having been achieved despite problems with the skips.”

In December 1985 the workmen of Celynen North were transferred to Oakdale and the colliery closed.

Some Statistics:

- 1913: Manpower: 203.

- 1915: Manpower: 180.

- 1916: Manpower: 350.

- 1918: Manpower: 685.

- 1919: Manpower: 600.

- 1920: Manpower: 950.

- 1923: Manpower: 1,021.

- 1924: Manpower: 767.

- 1926: Manpower: 960.

- 1927: Manpower: 800.

- 1928: Manpower: 1,195.

- 1930: Manpower: 1,350.

- 1931: Manpower: 1,500.

- 1932: Manpower: 800.

- 1933: Manpower: 1,872.

- 1934: Manpower: 1,860.

- 1935: Manpower: 1,530.

- 1937: Manpower: 1,884.

- 1938: Manpower: 1,915.

- 1940/2: Manpower: 1,800.

- 1944: Manpower: 1,500.

- 1945: Manpower: 1,287.

- 1947: Manpower: 1,208.

- 1948: Manpower: 1,192. Output: 272,000 tons.

- 1949: Manpower: 1,166. Output: 300,000 tons.

- 1950: Manpower: 1,192.

- 1953: Manpower: 1,069. Output: 351,000 tons.

- 1955: Manpower: 1,108. Output: 234,922 tons.

- 1956: Manpower: 1,126. Output: 248,377 tons.

- 1957: Manpower: 1,151. Output: 250,061 tons.

- 1958: Manpower: 1,126. Output: 244,633 tons.

- 1961: Manpower: 1,181. Output: 234,982 tons.

- 1962: Manpower: 1,187.

- 1969: Manpower: 895.

- 1970: Manpower: 859.

- 1971: Manpower: 811.

- 1972: Manpower: 814.

- 1974: Manpower: 780. Output: 170,000 tons.

- 1976: Manpower: 814.

- 1978: Manpower: 740. Output: 131,887 tons.

- 1979: Manpower: 608. Output: 168,000 tons.

- 1980: Manpower: 596. Output: 168,056 tons.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.