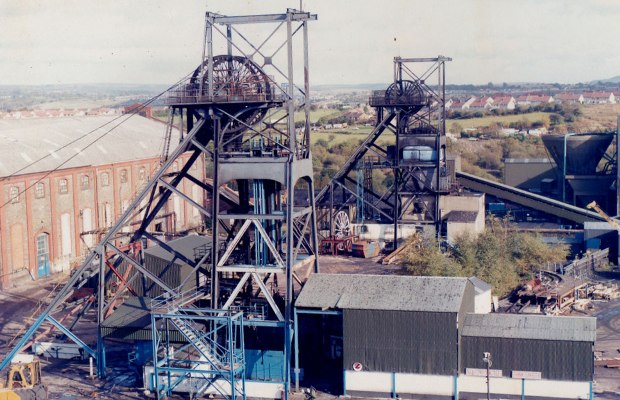

Penallta Colliery 1991

Copyright © William Rogers and licensed for reuse under this Creative Commons Licence

Ystradmynach (ST 1406 9578)

In 1882 the Powell Duffryn Steam Coal Company Limited acquired the mineral lease of Lord Tredegar’s lands to the south of New Tredegar and expanded into the mid-Rhymney Valley in a big way. Four of the largest and most profitable collieries in the South Wales Coalfield were sunk; Elliots in 1883, Bargoed in 1897, Penallta in 1906 and Britannia in 1910. At Penallta Colliery, the sinking of the two shafts started in 1906/7 on the outcrop of the Mynyddislwyn seam and was completed to the steam coal seams of the Lower and Middle Coal Measures in 1909. The mineral take consisted of an area about two miles from east to west and 3 miles from north to south with the colliery approximately in the centre.

The No.1 Pit (downcast ventilation) was started in October 1906 and was sunk to a depth of 783 yards, and the No.2 Pit (upcast Ventilation) was started on the 6th of June 1907 when the No.1 was 202 yards deep. It was sunk to a depth of 750 yards, with this pit being deepened to 800 yards in the 1950s. Both shafts were 21 feet in diameter and were 70 yards apart.

Powell Duffryn put out tenders for either steam or electric winding engines but electric winders were three times dearer than their steam counterparts. The steam winding engine for the No.1 Pit had a 24 feet diameter drum and was capable of raising six tons of coal in 45 seconds. Unfortunately, the one shaft was sunk with a slight bend in it, this being compensated by the installation of rigid guide rails for the carriages. The shafts had reached a depth of 400 yards when two bowks collided killing two of the sinkers.

Particular attention was given to the surface layout, with both winding engines being housed in one building along with modern electrical generators. This building measured 300 feet long by 70 feet wide. Not everything went smoothly though, for in July 1914 one of the electrical turbines “burst”, stopping the colliery and costing £4,000 to repair.

In 1910 this pit encountered trouble trying to open up in the south side due to steep gradients and disturbances in the Red Vein. The Red Vein was found to be between four feet and the seven seam was seven feet thick.

In February 1913 there was a sad event at the colliery: James Cosgrove, a railway platelayer aged 32 years, arrived at this pit around 7.30 am, wandered around for a while and then jumped down the No.1 Pit. Ben Morgan, a collier, said that on Saturday morning about 7.50 he saw the deceased jump over the gate, which was three feet six inches in height, and go down the shaft. Albert Kiu, a pitman, spoke to recovering part of the brain from the first byat, which was about 20 yards from the surface. and he found portions of the body a depth of 750 yards. The remains were badly mutilated. Mr. Frank B. Hann, the manager, in reply to the Coroner, said that the head had been recovered, but it was only partly recognisable. The deceased had worked for two hours on Thursday when he complained of illness and asked to be allowed to go. Witness had received no report of the strangeness of manner on the part of the deceased. The Coroner, summing up, said that from the evidence it appeared to be a clear case of suicide. The only question for the jury to the state of the man’s mind at the time of the act. Many persons thought that a man was necessarily mentally deranged before he would commit an act of that kind. The jury returned a verdict of “Suicide while of unsound mind.”

Among the Penallta miners who died in the War was a former manager, Killed in action, on July 26th Major John McMurtrie. M.C. R.E. was recently the manager at Penallta Colliery, Powell Duffryn Company, and son of the late James McMurtrie. of Radstock.

Mrs. Mansel of Mackintosh Terrace, Nelson, received official information Friday 11th of August 1917 that her husband. Private Thomas Mansel, Welsh Guards, died of wounds received on July 31st. Before being called up he was employed at Penallta Colliery. He leaves a widow and five children.

The manager of Penallta in 1909 was G.H. Lowrey, in 1912 it was D.A. Hann when this pit was working the Red and Six-Feet seams. In 1918 the manager was Abraham Moore who was still there in 1927. In 1928/30 the manager was A. Tait.

In December 1927 the manager, Mr. Tait, was praised for his design of a steel prop; Another prop which has for some time been successfully employed in actual service under South Wales conditions is that designed by Mr. Tait. the manager at Penallta Colliery. A steel girder construction was provided with a flat surface at the top end and tapered to a wedge shape at the lower end. Some of the men were not too happy with the introduction of these props, whereas, they claimed, the creaking and groaning of wooden props would warn a collier of an impending roof fall, steel would not. Management and the Mines Inspector believed them to be safe.

PENALLTA COLLIERY FALL. Steel pitprops are safe. it was stated at an inquest on Tuesday on Edward John Bryant (24). who was killed by a stone falling from the roof in the Penallta Mr. P. T. Jenkins, senior inspector of mines, said that more than 4.000 steel props were being used in the Penallta pits alone. “Accidental death” was the verdict.

21,396 tons of coal in a six-day week – a record for the colliery, was raised on the week-ending 21st December 1929. Most output records were achieved on the run-up to a Christmas, during ‘Bull Week’ which gave the collier a little bit extra in his wages for the festive season. Manpower at the colliery gradually increased until it reached a huge 3,208 men in 1931. The slump in the coal trade of that time reduced manpower to 2750 men on the surface of the mine and to 2,200 men underground in 1934.

Penallta Colliery was one of the first in the South Wales Coalfield to introduce mechanised coal extraction with the installation of Meco Moore power loaders at the coalfaces. When he reported back to Washington on the state of the South Wales Coalfield in 1922, the U.S. Ambassador stated; “The installation of the latest methods of machine mining has been introduced into the valley by the Powell Duffryn Co., and coal cutters and conveyors are now the means adopted for working the measures. A great deal of prejudice had to be overcome, particularly among the older colliers, but it is now generally agreed that the conveyor system is both less arduous and safer than the old methods. An additional advantage is that seams hitherto considered unworkable on account of their thinness can be exploited and a far greater amount of rubbish is stowed underground, thereby releasing the pits to a great extent and allowing them to wind coal instead of rubbish.”

In 1943/5 the manager was C.H. Davies and the colliery employed 1,557 men working underground in the Rhas Las, Seven-Feet, Six-Feet and Four-Feet seams and 361 men working at the surface of the mine.

In January 1944 a complaint was raised in Parliament that breakdowns in transport for the colliers at this colliery was causing a loss of coal and payments to the men under the Essential Work Order. In June 1944 a coalface in the Upper Four-Feet seam was selected for experiments with double roadside packing to help support the roadways. The seam was five feet thick and the coalface was 208 yards long and had a 48-hour turnover system which the conveyor and supplying the face was on the afternoon shift and packing was done by nights. To give 700 tons of coal every two days with 30 colliers employed on the dayshift. In the last six months, 24,019 hundredweight trams of rubbish had to be brought into the district to fill the packs. During that time this face produced 52,577 tons of coal.

On Nationalisation of the Nation’s coal mines in 1947, Penallta Colliery was placed in the National Coal Board’s, South Western Division’s, No.5 (Rhymney) Area, Group No.5, and at that time employed 320 men on the surface of the mine and 1,614 men working in the Rhas Las (Upper-Nine-Feet), Seven-Feet, Six-Feet and Four-Feet seams.

The hoped co-operation between management and men due to the ‘people’ owning the mines did not materialize, PD managers remained in power and strikes continued:

1,800 NOW OUT AT ‘ STAY-DOWN’ PIT stay-in strike of 26 miners at Penallta Colliery. Ystradmynach. Glamorgan, which started on Monday, resulted in 1,800 other miners not descending the pit yesterday. The 1,800 stayed out on the recommendation of the lodge committee, which feared an extension of stay-in strikes. The men below, who are striking over payment of allowances for abnormal conditions of work, arc being fed every four or five hours. They pass the time singing Welsh hymns and playing quoits with old horseshoes. Last night they organised a brains trust. the lodge committee keeping in touch with them by telephone. Already more than 3,000 tons of coal have been lost.

The colliery had its own coal preparation plant (washery). The manager was R.D. Rhydderich who was still there in 1949 and in 1953 the manager was A. Sullivan.

On the 4th of February 1948 twenty-five miners ended a stay down strike that had stopped this pit for 62 hours. The South Wales Miners Federation was based on international socialism, so it came as a surprise to me that many pit lodges in South Wales refused to have displaced Polish labour after the war. This was Penallta’s reason:

Mr. Gwyn Phillips, secretary of Penallta Colliery Lodge, interviewed by a Mail reporter last Light, said: “Following the first approach last week on behalf of Penallta Colliery management regarding the employment of Poles; the lodge committee decided against the proposal because the strong objection was taken to Poles visiting ‘the colliery before the lodge had agreed to their acceptance. “It was also felt that the best use was not being made of existing manpower. The fact that Poles were visiting the colliery this very day the matter was being discussed by the lodge was contrary to the national agreement that Poles, should not enter any mine before the consent of the local miners’ lodge was obtained.” The men say they had understood from the management that the colliery was saturated as far as unskilled labour was concerned. No further representation has been made by the management since the lodges refusal and no further action has been taken by the men, but the question is likely to be discussed when the lodge committee meets today. It is understood that about 140 Poles are now living nearby. At the Miners’ Hostel, Ystradmynach. About 80 of them are not in employment. The rest are employed at neighbouring collieries to the Penallta Colliery, which is the biggest in South Wales employing about 2,004 men.

The same issue arose in September 1948: Eighteen hundred miners at Penallta Colliery (Glam) have decided to strike Monday if 12 Yugoslavs allocated the mine not been withdrawn by then. Militancy by the men at the pit continued into 1949 when a visit by Labour Party leader Hugh Gaitskill had to be called off due to the men stating that they would boycott it due to the ‘window dressing’ of the pit prior to the visit.

In 1955 out of a total colliery manpower of 1,902 men, 809 of them worked at the coalfaces, this coalface figure dropped to 763 men in 1956, it further dropped to 710 men working at the coalfaces in 1957, but rose to 735 men at the coalfaces in 1958. In 1961 out of the total colliery manpower of 1,508 men, 603 of them worked at the coalfaces.

In 1962 the winding engines were converted from steam to electric power as part of improvements to the mine that cost £2.5 million and the shafts deepened to 2,400 feet so as to open up the Four-Feet seam. The 1,890 h.p. winding engine could handle fifty men or six tonnes of materials per wind while battery locomotives were used underground and could haul 50 mine cars per journey.

In July 1963 the National Coal Board informed the local urban district council that they might have to close this mine due to a manpower shortage unless the council built 300 houses for new miners.

In 1969 this colliery was placed on the NCB’s jeopardy or closure list and warned that if production did not improve it would close. The reprieve came in July of that year when it exceeded its output per man shift target of 28 hundredweights by hitting 31.6 hundredweights.

In December 1978 a fire occurred on the No.2, 65 h.p. electric locomotive when it was about 1,380 metres from the No.1 Pit. The driver managed to put the fire out.

In the 1970s all mining operations at Penallta Colliery were concentrated on the Seven-Feet seam. In 1978 it was working an area of four square miles with 8 miles of roadways including 2 miles of high-speed conveyors and 1.5 mile long locomotive plain. At a depth of 2,400 feet, they were amongst the deepest workings in the Coalfield. In 1979 the M19 coalface was the best performing coalface in the South Wales Coalfield in the 120 cm to 149 cm seam thickness group. It produced 639 tonnes a day.

In 1981 the colliery was working this seam at a section of 51 “, with coalface length varying from between 220 and 270 yards. Coal cutting was carried out by ranging drum shearers and coalface roof supports were the self-advancing types. Output per man shift at the coalface was expected to be 6.56 tonnes.

The colliery was working normally within a month of the return to work after the 1984/85 miner’s strike. The NCB stated that at Penallta: Good conditions on both faces had led to normal production levels being achieved. Towards the end of 1985, this colliery was allocated £3.5 million to equip a new ‘super’ coalface to ensure the future of the mine. Plans were also drawn up to install skip winding in the shafts at a cost of £4 million in an effort to raise the winding capacity, and it was agreed to modernise the washery.

There was a set-back in January 1987 when mines rescue teams battled for two days to put out an underground fire. But nevertheless, the colliery started to break its own productivity records within 1989 its single coalface in the Seven-Feet seam produced 500,000 tonnes of coal. In 1990 the colliery produced 590,000 tonnes of saleable to feed Aberthaw Power Station.

At Penallta Colliery it was stated that the economically workable reserves of coal had been exhausted. On the 29th of March 1991, the workmen, at a special meeting decided not to fight the closure, despite the NUM recommending that it goes through the review procedure.

Penallta Colliery was closed by British Coal on Friday 1st November 1991. The manager at that time was D. Fox. It was the last deep mine to work in the Rhymney Valley with many of the surface buildings now listed. The pit was decommissioned and finally closed in 1992.

In 1996 the site was given a make-over with the old tipping area changed into a community park and the colliery site used for housing, although some of the main buildings and the headgears have been retained.

Some of the early fatalities at this colliery:

- 29/6/1910, Job Rossiter, aged 25, hard groundman, electric shock.

- 30/7/1910, John Hough, aged 33. Repairer, fall of roof.

- 13/11/1911, Thomas (Rhondda) Jones, aged 41, collier, fall of the roof.

- 26/6/1912, George Jones, aged 19, collier boy, fall of the roof.

- 1/12/1912, William McKay, aged 26, labourer, fall of roof.

- 21/5/1912,Henry David Owen, aged 40, collier, crushed by trams.

- 25/2/1913, David Evans, aged 55, mason contractor, Frank Lewis, aged 34, labourer, both were crushed by trams.

- 26/2/1913, William Lewis, aged 43, overman, crushed by trams.

- 7/10/1913, John Henry Williams, aged 27, timberman, strain.

- 6/12/1913, Charles Runciman, aged 20, labourer, fell down the shaft.

- 15/12/1913, Theo Jeffries, aged 30, timberman, fall of roof.

- 20/12/1913, Thomas Taylor, aged 63, oiler, run over by wagons.

- 22/7/1914, Clifford Andrews, aged 17, shackler, crushed by trams.

- 28/11/1914, Henry Greedy, aged 47, repairer, was killed by the cage in the shaft.

- 10/1/1925, Arthur Davies, aged 50, labourer, crushed by trams.

- 24/3/1925, David Davies, aged 51, haulier, crushed by trams.

- 11/4/1928, Harold C. Coward, aged 17, collier boy, fall of the roof.

Besides the deaths, there was a terrible roll of accidents, below is the list from just one year, 1913:

- 12/01, Benjamin Jones, age 35, Foreman smith: Repairing kep when the cage moved – crushed between cage band and collar board.

- 2/02, David Mainwaring, age 39, Fireman: Fall of stone.

- 25/02, George Underwood, age 33, Haulier: Three trams of rubbish standing on an inclined road, on a scotch, were bumped into by a set which had come down to pick them up. The scotch got displaced and they ran away and struck the men working 90 yards below. Two other persons were injured. 2 killed.

- 25/02, David Evans, age 55, Mason contractor: Three trams of rubbish standing on an inclined road, on a scotch, were bumped into by a set which had come down to pick them up. The scotch got displaced and they ran away and struck the men working 90 yards below. Two other persons were injured. 2 killed.

- 25/02, Ernest Ellis, age 26, Mason: Three trams of rubbish standing on an inclined road, on a scotch, were bumped into by a set which had come down to pick them up. The scotch got displaced and they ran away and struck the men working 90 yards below. Two other persons were injured. 2 killed.

- 17/03, E. Bairstowe, age 30, Electrician: Placed connectors of an ammeter on motor terminals and got burnt.

- 4/03, Thomas Williams, age 44, Miner: Fall of side.

- 12/04, Frederick Hoale, age 26, Labourer: Crushed by tram.

- 30/04, Edward Dyer, age 34, Haulier: Crushed by tram against the post.

- 22/05, David T Harris, age 34, Collier: Fall of stone.

- 28/05, David Lewis, age 37, Collier: Fall of stone.

- 23/06, John Baker: aged 40, Collier: Crushed by tram.

- 7/07, Obidiah Lewis, age 38, Haulier: Putting the collar on the horse when it turned and crushed him.

- 6/08, Frederick Smith, age 50, Collier: Struck by haulage rope.

- 19/08, Albert Roberts, Age 40, Collier: Fall of stone.

- 2/09, Thomas Owen, age 23, Collier: Gun fell on his knee.

- 23/09, Milsom, age 33, Collier: Fall of stone.

- 7/10, John Henry Williams, age 27, Timberman: He appears to have strained himself when lifting a tram. 21/11, Zachariah Davies, age 40, Haulier: Kicked by horse.

- 3/12, Alfred Jenkins, age 36, Pumpsman: Fall of the roof.

- 6/12, Charles Runciman, age 20, Labourer: He was descending, with 19 others, in a cage. It appears that before the cage reached the pit bottom one of the men raised the cage fence, and the deceased, who was slightly leaning against it, fell out and was killed.

- 15/12, D. Dwyer, Asst timberman: Fall of the roof on the roadway. A large stone fell from the roof and knocked out some timber and staging adjoining; he was killed by the fall, two others received injuries.

- 15/12, Theo Jeffires, age 30, Timberman: Fall of the roof on the roadway. A large stone fell from the roof and knocked out some timber and staging adjoining; he was killed by the fall, two others received injuries.

- 15/12, George David Jones, age 33, Asst timberman: Fall of the roof on the roadway. A large stone fell from the roof and knocked out some timber and staging adjoining; he was killed by the fall, two others received injuries.

- 1909: Manpower: 291.

- 1910: Manpower: 633.

- 1911: Manpower: 270.

- 1912: Manpower: 1,423.

- 1913: Manpower: 1,281.

- 1915: Manpower: 1,800.

- 1918: Manpower: 2,160.

- 1919: Manpower: 1,900.

- 1920/2: Manpower: 2,500.

- 1923: Manpower: 2,395.

- 1924: Manpower: 2,580.

- 1925: Manpower: 2,500.

- 1926: Manpower: 2,550.

- 1927: Manpower: 2,753.

- 1928: Manpower: 2,611.

- 1930: Manpower: 3,124.

- 1931: Manpower: 3.208. Output: 860,000 tons.

- 1932: Manpower: 3,248.

- 1933: Manpower: 2,461.

- 1934: Manpower: 2,135.

- 1935: Manpower: 2,450. Output: 700,000 tons.

- 1937: Manpower: 2,388.

- 1938: Manpower: 2,354.

- 1940: Manpower: 2,168.

- 1941: Manpower: 2,188.

- 1942: Manpower: 1,977.

- 1944: Manpower: 1,870.

- 1945: Manpower: 1,918.

- 1947: Manpower: 1,934.

- 1948: Manpower: 1,941. Output: 579,020 tons.

- 1949: Manpower: 1,974. Output: 579,000 tons.

- 1950: Manpower: 1,968.

- 1953: Manpower: 2,004. Output: 565,000 tons.

- 1954: Manpower: 1,935. Output: 500,000 tons.

- 1955: Manpower: 1,902. Output: 455,823 tons.

- 1956: Manpower: 1,926. Output: 442,172 tons.

- 1957: Manpower: 1,873. Output: 455,475 tons.

- 1958: Manpower: 1,795. Output: 395,685tons.

- 1960: Manpower: 1,528. Output: 288,296 tons

- 1961: Manpower: 1,508. Output: 266,095 tons.

- 1962: Manpower: 1,555.

- 1964: Manpower: 1,491.

- 1967: Manpower: 1,042. Output: 297,322 tons.

- 1968: Manpower: 965. Output: 249,609 tons.

- 1969: Manpower: 865. Output: 266,490 tons.

- 1970: Manpower: 858. Output: 278,457 tons.

- 1971: Manpower: 815. Output: 180,716 tons.

- 1972: Manpower: 787. Output: 190,697 tons.

- 1973: Manpower: 726. Output: 119,378 tons.

- 1974: Manpower: 727. Output: 112,386 tons.

- 1975: Manpower: 723. Output: 162,811 tons.

- 1976: Manpower: 709. Output: 185,323 tons.

- 1977: Manpower: 686. Output: 225,759 tons.

- 1978: Manpower: 690. Output: 224,648 tons.

- 1979: Manpower: 639. Output: 191,798 tons

- 1980: Manpower: 634. Output: 191,828 tons.

- 1981: Manpower: 671.

- 1984: Manpower: 645.

- 1990: Manpower: 650.

- 1992: Manpower: 522.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page