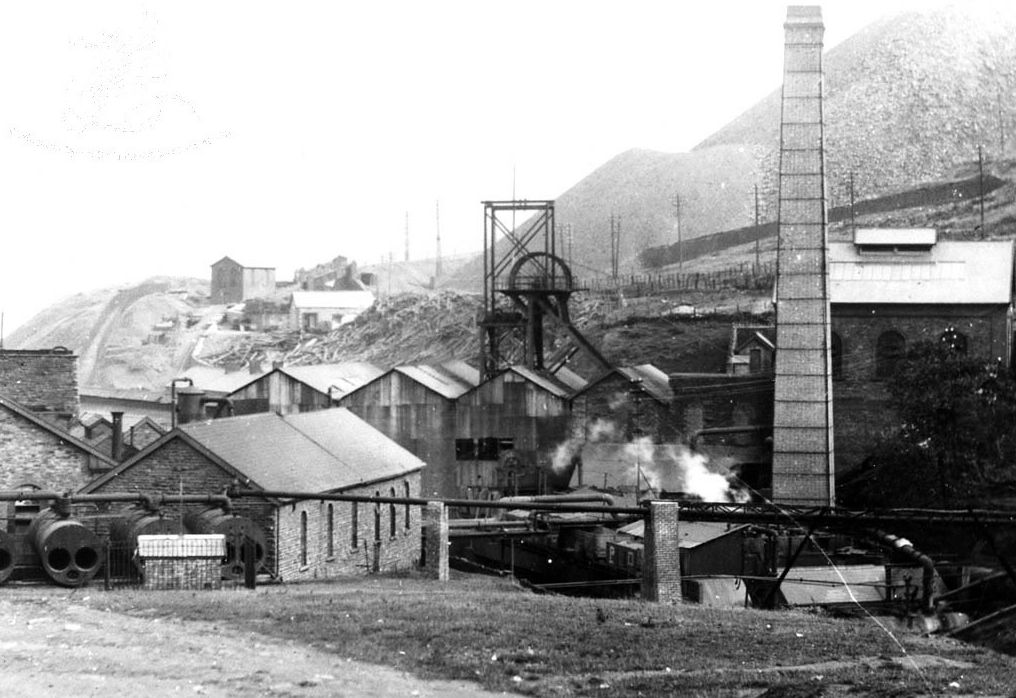

Near Aberaman, Cynon Valley (ST 0072 9978)

Near Aberaman, Cynon Valley (ST 0072 9978)

This colliery was wedged between Aberaman Colliery which was approximately half a mile to the north-east and Fforchaman Colliery which was approximately half a mile to the south-west. It was locally called Morris’pit’.

It was sunk to the Four-Feet seam by Martin Morrison and John and Charles Carr in 1848, making it the first pit in the Cwmaman area, and used the water balance method of winding until 1855.

On the 28th November 1855, eight men were killed in an over-winding accident in which they were thrown down the pit. Instead of creeping towards the bank the carriage shot up like a dart, past the banksman and crashed heavily into the headgear above him. The occupants were thrown 240 yards down the shaft to their deaths. Those who died were all listed as miners- Thomas Jones aged 30 years, Philip Kelly aged 25 years, both left a wife and two children, David Thomas aged 24 years, left a wife and child, Samuel Thomas aged 25 years, Jenkin Davis aged 24 years, William Thomas aged 17 years, William Hooper aged 17 years and Richard Weeks aged 23 years.

At the inquest into the men’s deaths, held at the Boot Hotel, Aberdare, it emerged that there was a very casual system of signalling in operation between the shaft and the engine house. The jury said nothing about these shortcomings but delivered a verdict of manslaughter against the engine driver. He was new to the work and it was alleged that if he had counted the number of engine strokes made during the ascent, he would have known that the carriage was nearing the bank.

Solomon Lloyd aged 21 years appeared at Glamorgan Winter Assize to answer the charges. He was defended by a barrister nominated from the well of the Court by Mr. Justice Vaughan Williams who found the defendant ‘Not Guilty’. The prisoner appeared greatly affected by the serious position he had been placed in and wept during the trial.

Cwmneol is listed as being owned by Carr and Morrison in 1858. It was owned by D. Prothero and Company in 1860 and by United Merthyr Collieries Company Limited in 1865 and sold in 1866 to Sir George Elliot the founder of the Powell Duffryn Steam Coal Company.

The South Pit was sunk to a depth of 1,041 feet 3 inches, and the North Pit to a depth of 1,078 feet 7 inches. One of the main seams to have been worked was the Seven-Feet seam which had a thickness of 63 inches.

The manager in 1878 was L. Evans and in 1884 it was Rees Rees. Following the death of Thomas Powell, Sir George Elliot formed a partnership with Thomas Forster and William Armstrong and bought Powell’s pits and floated the Powell Duffryn Steam Coal Company Limited.

In 1866 High Duffryn, Aberaman, Treaman, Cwmneol and Fforchaman pits were purchased and the Company headquarters was situated at Aberaman.

The slump in the coal trade of 1875 resulted in the closure of High Duffryn, Upper Duffryn, Abergwawr and Lower Duffryn, with only the Lower Duffryn re-opening. By 1878 of the 39 pits in the Cynon Valley, Powell Duffryn owned 12 of them. In 1881 the Company sank the George Pit and purchased Abercwmboi from D. Davis and Sons. Powell Duffryn, which was to become the most powerful coal mining company in the world, now started to expand out of the Cynon Valley and spread to the Rhymney Valley and Llantrisant areas. However, they still had not finished with the Cynon Valley and in 1893 the Middle Duffryn was deepened, in 1900 the Lletty Shenkin Colliery was bought, and in 1909 they purchased Ysguborwen Colliery. Between 1893 and 1898 this colliery was closed.

It was then deepened and revamped with new boilers, screens, sidings, stores, lamproom etc. A new winder with two cylinders 28 inches in diameter and with a 46-inch stroke, and with a 12 feet diameter drum was installed. Underground coal-cutting machinery was installed and by 1918 it was working the Nine-Feet, Red and Bute seams. The Seven-Feet seam was unworkable in this area. In 1908 this colliery employed 697 men underground and 70 men on the surface with the manager being W.E. Jayne. In 1913 annual coal production of Powell Duffryn was 3,874,000 tons with 13,600 men employed, 5,000 of these in the Cynon Valley, and 681 men at Cwmneol.

Powell Duffryn produced a 50 year booklet in 1914 which had this to say about Cwmneol;

The Cwmneol Colliery was acquired in 1866, at the same time as the Fforchaman. In 1893 owing to the depression in the coal trade Cwmneol was stopped, but instead deepening operations were commenced and the engine and boiler arrangements improved, new screens erected, sidings extended and new buildings for stores and lamproom put up. The 7 feet seam proved split up by thick bands of stone and very variable. The yard seam was quite thin and no trace was found of the Gellideg, so far as the position of the shafts was concerned.

However, there are three other seams being worked, the 9ft., Red Vein and Bute, and as machine cutting and face conveying machines are becoming more successful in the extraction of such seams as these, the Colliery is still working.

The winding at Cwmneol is done by a Fraser and Chalmers cross compound engine with cylinders 28 in and 46 in with a 5ft stroke. The drum is parallel and 12 ft in diameter.

The air compressors are two in number, one being a cross compound two stage, by Robey & Co, with steam cylinders 25 in and 44 in diameter, and air cylinders 26 in and 40 in in diameter, with a 4 ft stroke at 75 R.P.M. The capacity of this compressor is 5,000 cubic feet of free air per minute.

The other is a cross compound, two stage engine by Fraser and Chalmers with steam cylinders 36 in and 57 in diameter, and air cylinders 33 in and 52 in diameter, with a 4 ft stroke at 75 R.P.M. The capacity of this engine is 8,000 cubic feet of free air per minute.

For ventilation purposes there are two engines:

-

- Old fan engine, tandem compound cylinders 15 and 25.5 in, with a 4 ft 6 in stroke at 45 R.P.M.

- New fan engine, Tandem compound Paxman Lentz, with cylinders 16 and 26 in with a 27.5 in stroke.

The electric machinery is as under:

-

- Three underground haulages; 160, 150, 250 H.P. motors

- Fan motor 250 H.P.

- Screens motor 50 H.P.

- Rubbish motor 50 H.P.

- Blacking motor 50 H.P.

In 1916 it employed 800 men, in 1918 the pit employed 765 men underground and 105 men on the surface, and in 1919 it employed 850 men. The manager in 1915/19 was J.W. Jordan. The manager in 1923 to 1930 was John Barry or Barrie. This pit re-opened on the 7th of February 1929 after being closed since the previous June due to the trade depression.

In 1931 unemployed within the Coalfield stood at 36% rising to an incredible 47% in 1932, in the period 1933, 1934, 1935 the figures remained devastatingly high at 42%, 44% and 34% respectively, indeed they could have been much higher except for the relative prosperity of the anthracite section of the Coalfield, and for workmen leaving the area to seek work elsewhere – almost 22,000 men in the period 1931 to 1935.

The Rhondda/Port Talbot registration area was particularly badly hit during this period with unemployment peaking at 60% in 1932. Three men were killed in a shaft incident on the 17th of August 1930, the men were own pit bottom when the rope broke on the cage and it dropped and crushed them. They were:

- H. Harry, married, aged 60 of Kingsbury Street, Cwmaman

- William Joyles, married, aged 45 of Elizabeth Street, Aberdare

- Glyn Jones, single, aged 22, of Gwaur Street, Aberaman.

In 1935, Powell Duffryn’s output in the Cynon Valley was 855,000 tons of coal with 2,690 men employed, at Cwmneol 30 men were employed on the surface and 150 men underground producing 180,000 tons of coal, although these figures may be taken with caution as 180,000 tons is a tremendous amount for 150 men to produce. In 1934 this colliery was managed by C.L. Watson. In 1938 T.J. Hughes was manager and this pit employed 552 men.

In 1943/5 the manager was J.S. Evans and it employed 383 men working underground in the Two-Feet-Nine, Yard and Four-Feet seams and 93 men working on the surface. Cwmneol Colliery came under National Coal Board control on Nationalisation in 1947 and was placed in the South Western Division’s, No.4 (Aberdare) Area whose headquarters were at the old Powell Duffryn headquarters at Aberaman.

In 1947 Cwmneol employed 69 men on the surface and 247 men underground working the Two-Feet-Nine and Four-Feet steam coal seams the manager was PD. Haman. Cwmneol Colliery was closed by the National Coal Board on January 31st 1948 due to the exhaustion of coal reserves.

Some of those who died at this pit:

- 17/6/1877, Edward Evans, aged 22, collier, fall of roof

- 3/7/1877 Thomas Hoare, aged 13, collier, fall of roof

- 13/12/1877 David Phillips, aged 49, fireman, shaft incident

- 31/3/1879 Israel Davies, aged 50, timberman, fall of roof

- 6/3/1880 John Jones, aged 12, door boy, crushed by trams

- 23/3/1880 Evan J. Williams, aged 13, door boy, run over by trams

- 11/10/1881 John Thomas, aged 16, shackler, fall of roof

- 25/7/1884 John Thomas, aged 15, collier, fall of roof

- 4/12/1884 John Lloyd, aged 33, collier, shaft incident

- 12/6/1885 John Edwards, aged 19, lampman, run over by trams

- 28/4/1887 Christopher Veal, aged 13, collier, run over by trams

- 16/7/1887 David Davies, aged 16, collier, run over by trams

- 10/4/1888 Samuel Reed, aged 19, haulier, fall of roof

- 16/1/1889 Thomas J. Jones, aged 17, shackler, crushed by trams

- 22/3/1892 Frederick Ponting, aged 15, collier boy, fall of roof

- 28/4/1893 Rees Rees, aged 15, collier boy, run over by trams

- 9/9/1899 William Arnold, aged 29, ostler, shaft incident

- 20/11/1911 David Williams, aged 65, sheavesman, knocked down by a horse

- 27/5/1914 William Lynch, aged 22, collier, fall of roof

- 30/12/1914 Rufus Enoch, aged 18, engine driver, caught in machinery

Some Statistics:

- 1870: Manpower: 400.

- 1889: Output: 177,949 tons.

- 1899: Manpower: 60.

- 1900: Manpower: 123.

- 1901: Manpower: 228.

- 1902: Manpower: 295.

- 1903: Manpower: 367.

- 1905: Manpower: 180.

- 1907: Manpower: 601.

- 1908: Manpower: 767.

- 1909: Manpower: 767.

- 1910: Manpower: 793.

- 1911: Manpower: 836.

- 1912: Manpower: 611.

- 1915/6: Manpower: 800.

- 1918: Manpower: 870.

- 1919: Manpower: 850.

- 1920: Manpower: 1,000.

- 1922: Manpower: 1,150.

- 1923: Manpower: 1,308.

- 1924: Manpower: 1,301.

- 1926: Manpower: 1,300.

- 1927: Manpower: 1,057.

- 1928: Manpower: 1,108.

- 1929: Manpower: 1,000.

- 1930: Manpower: 771.

- 1931: Manpower: 806.

- 1932: Manpower: 818.

- 1933: Manpower: 293.

- 1934: Manpower: 355. Output: 180,000 tons.

- 1937: Manpower: 606

- 1938: Manpower: 552.

- 1940: Manpower: 569.

- 1941: Manpower: 597.

- 1942: Manpower: 626.

- 1944: Manpower: 546.

- 1945: Manpower: 476.

- 1947: Manpower: 316.

- 1948: Manpower: 216. Output: 61,000 tons.

In February 1960 an extraordinary act of heroism was carried out as shown by this article in the Coal News:

He crawled 300 ft up the shaft, saved three men

Crawling more than 300 feet up helped three workmen trapped in a faulty cage.

Mr. Jones has been awarded the Daily Herald Order of Industrial Heroism, which is often known as the ‘workers’ VC.’

A party of workmen were sent to repair a cage, and three men went down to check the cage. As the cage was slowly being taken back to the surface after the removal of a section of guide rail, it broke down leaving the men suspended 315 feet from the pit bottom and without means of signalling the surface.

Mr. Jones found another way to the bottom of the shaft and then climbed up the cage shaft, crawling through water, oil and muck, and reached the cage.

While hanging in the shaft, Mr. Jones improvised a signalling system and, after climbing back to the bottom, guided the cage safely down.

It took nearly five hours to release the men. If the cage had broken away Mr. Jones would have been crushed to death.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page