In 1880 the Blaenavon Iron and Coal Company Limited re-organised many of the old workings in the Forge Side area and formed the Big Pit. These included the; Coity Pit (No.3 pit) which was sunk in 1840 and became the Big Pit upcast shaft. It was 135 feet deep and nine feet in diameter. Kearsley’s Pit which was deepened from the Three-Quarter (Six-Feet) seam at a depth of 128 feet to the Old Coal (Five-Feet /Gellideg) seam at a depth of 293 feet, it was originally sunk in 1800 and was five feet in diameter.

In 1880 the Blaenavon Iron and Coal Company Limited re-organised many of the old workings in the Forge Side area and formed the Big Pit. These included the; Coity Pit (No.3 pit) which was sunk in 1840 and became the Big Pit upcast shaft. It was 135 feet deep and nine feet in diameter. Kearsley’s Pit which was deepened from the Three-Quarter (Six-Feet) seam at a depth of 128 feet to the Old Coal (Five-Feet /Gellideg) seam at a depth of 293 feet, it was originally sunk in 1800 and was five feet in diameter.

The Nos.1 & 2 pits were sunk between 1860 and 1863 to the Three-quarter seam and were deepened in 1897 to the Five-Feet/Gellideg (Old Coal) seam. The No.1 Pit was 98 feet deep and elliptical in shape 18 feet by 13 feet while the No.2 Pit was 135 feet deep and nine feet in diameter. The No.4 pit was only 35 feet deep and five feet in diameter and was sunk around 1800.

This pit was thought to be unique in that its shafts were sunk on a fault line enabling roadways to be driven into different seams from different sides of the shafts on the same level.

The seams worked at this colliery:

- The Two-Feet-Nine seam was found at a depth of 76 feet and had a section of 42 inches.

- The Upper-Four-Feet seam was at a depth of 100 feet and had a section of 36 inches.

- The Upper-Six-Feet was at a depth of 127 feet and had a section of 54 inches.

- The Upper-Nine-Feet seam was at a depth of 196 feet and had a section of 48 inches.

- The Lower-Nine-Feet seam was at a depth of 215 feet, and the Bute seam was at a depth of 224 feet.

- The Yard/Seven-Feet (Meadow Vein) seam at a depth of 295 feet and had a section of 42 inches.

- The Five-Feet/Gellideg (Old Coal) seam at a depth of 30 feet and had a section of 54 inches, and the Garw seam was at a depth of 442 feet and had a section of 32 inches.

By the closure of the colliery in 1980 only the Garw seam was left to work.

In 1888 the pit was working the Three-Quarter seam, Old Coal, Horn Coal (Upper-Nine-Feet) seam and the Bottom Vein iron ore seam. The manager at that time was P. Williams.

In the 1890s there were four underground haulage engines supplied by Cornish type boilers at the surface. The one in the Old Coal seam had two 18-inch cylinders and worked a haulage plain over 1,200 yards long which dipped by 1 in 12.

In 1896 Big Pit employed 421 men underground and 107 men on the surface with the manager being still P. Williams. In 1908 the manager was C. Davies, while in 1913 the manpower was 1,145 men, with the manager being G.P. Williams.

The Twentieth Century had just begun and the World demanded more and more south Wales coal, the Bristol Channel became the busiest waterway in the world and the South Wales Coalfield was the top coal exporting area in the world. The coal industry and this area was at its peak, jobs were plentiful and people flooded into the Valley.

On the 7th of April 1913 a fire broke out near the pit bottom, three men, Arthur Tucker aged 26 years, J. Jenkins aged 43 and William Bond aged 30 years, decided to go around to the inside of the fire – they died from the fumes of the fire. Later on in that year, the 20th of October, George Henry Jenkins aged 40 years, and the head hitcher on the pit bottom went inbye to find out why the haulage signal bell was constantly ringing. He found that the signal wire had been caught under a fall, but the fall also released methane gas which ignited when it met the flame from his naked lamp and killed him.

In 1915 the Blaenavon Company Limited had a surface and mineral area of 5,259 acres and controlled six collieries and 2 blast furnaces which were capable of an annual output of 150,000 tons of pig iron. It also owned a tyre mill and rail mills. A report of its accounts in a booklet issued by the Business Statistics Company in 1915 showed that between 1903 and 1914 it made a profit of £296,166. In 1915 the board of this company consisted of; R.W. Kennard, Chairman, G. Mure Ritchie, Fred J. Gordon, C.C. Macrae and M. Deacon.

The manager in 1918/23 was C. Humphreys and in 1927 it was W. Daniel.

In February of 1934 the Colliery Guardian reported that the coke ovens and by product plant at this colliery was starting up for the first time since 1926.

In September 1934 the newspapers reported:

Nanty Hughes, 27, a collier, at the Big Pit, Blaenavon, Mon, was caught beneath a fall of roof, and it was an hour before he was extricated. During the rescue operations, an enormous stone was seen to be slipping from the top of the low roof. Without a thought for his own peril, Reginald Jones, a young collier, of Forge Side, Blaenavon, stepped beneath the stone and supported it with his back while Hughes was being released. After Hughes had been removed from danger Jones jumped clear and the stone crashed to the ground. Hughes is in hospital with serious injuries to the spine and legs.

By 1935 the pit was in the Elled (Two-Feet-Nine) seam, the Black Vein (Lower-Nine-Feet) seam, Yard, and Old Coal seam producing steam, house and gas coals, employing 1,500 men underground and 700 men on the surface producing 600,000 (I would treat this figure with caution) tons of coal. 72 coke ovens were now in production at the pit. The manager at that time was W.E. Rouzel. He was there in 1930 and was still manager in 1938.

On the 5th of May 1939, Geoffrey Lloyd, the Government’s Secretary for Mines, visited this pit, with The Times report of the visit gives an interesting insight into the workings of that time.

…visited a mine where 97 per cent of the output is cut by machines and transported by conveyors and jiggers.

The post-war mechanization in mines has introduced a new element in the problem of making mines safe, and a Bill to this end will be presented in the next session of Parliament.

The Big Pit of the Blaenavon Iron and Coal Company, which Mr. Lloyd visited today, is at the north-eastern outcrop of the South Wales Coalfield, which brings the bottom seam of the coal measures to a depth of only 98 yards from the surface. It has an output of about 6,000 tons a week from four seams and gives employment to 800 men on three shifts. Unlike the Ammanford Colliery, visited yesterday, dust is not a major problem here; on the contrary, it is a wet colliery, with water dripping from the roof and running in channels along the sides of the main haulage roads. Electricity is extensively used, even so far in as the actual coalface, and since it is a non-gaseous mine, naked lights are employed and smoking is permitted.

The descent was made by cage, and in addition to the customary overalls, the visitors wore knee-high gumboots. From the pit bottom the party went about 800 yards to the working faces in the Garw seam, which is only 2 ft 4 in thickness, with a rock roof and floor. Here Mr. Lloyd spoke with men at work undercutting the coalface with machinery, and himself crawled on hands and knees for a distance of about 100 yards. It was explained to Mr. Lloyd that because of the thinness of the coal and the character of the rock it had been found to be impractical to work this seam hitherto, and it was possible to work it now only by the use of machinery. The machines undercut the coal to a depth of 5 ft and the coal is afterwards brought down by blasting. Mr. Lloyd chatted to some of the men who were boring holes for the charges, and saw how inhalation of dust is prevented by the use of respirators, he also saw (and heard) the working of belt and jigger conveyors, with their attendant dangers, and so had a demonstration of the need for further regulations to meet the conditions brought about by machine mining, for which there is no provision in the Coal Mines Act. Mr. Lloyd remained underground for about two hours.”

On the 1st of February 1939 new pit head baths were constructed at a cost of £17,000.

In 1945, E. Turner was manager. At that time the Blaenavon Company Limited was based at Blaenavon with the directors being; G. Mure Ritchie, M. Deacon, Percy C. Quitter, H. Spence Thomas and John H. Lones. This company was working the Big Pit, Kays Slope and Garn Slope which produced 600,000 tons of coal for that year between them.

From its formation to nationalisation there were 52 fatalities at this colliery including two men who were killed under a fall roof on 12/12/1911 and three men suffocated by a gas outburst on 7/3/1913. The main causes of death were roof falls in which 28 miners died and haulage accidents in which 11 miners died.

Following Nationalisation the NCB decided to place the whole of the mineral take in the Blaenavon area, including the collieries of Big Pit, Garn Slope, Kay’s Slope, and Viponds Colliery into one super-pit which they called Blaenavon. It was believed would extend the mining life of the area by thirty years, and from that time all the men were to descend down Big Pit.

The mineral take would then cover an area of nine square miles and it was claimed yield the following reserves;

| Reserves | Deakins | Big Pit | Garn/Kays | Others |

| Elled | 500,000 | |||

| Big Vein | 51,000 | 1,500,000 | 250,000 | |

| Horn Coal | 120,000 | |||

| Black Vein | 80,000 | |||

| Meadow Vein | 1,300,000 | 2,120,000 | 1,000,000 | |

| Yard | 1,600,000 | 1,600,000 | 500,000 | |

| Old Coal | 750,000 | |||

| Garw | 660,000 | 2,500,000 | 1,600,000 | 700,000 |

| TOTALS | 711,000 | 8,150,000 | 5,770,000 | 2,200,000 |

The plan was to drift 1,200 yards down at an incline of 1 in 6 from the surface at Big Pit to the Garw seam in the vicinity of the pit bottom. The first stage would then be to transfer Deakins’ production by underground roadway the 2,200 yards to Big Pit. The distance from the coalface to the mouth of Deakins Slope had been 3,100 yards. The second stage was then to install a trunk conveyor to the surface.

In the marginally ‘warmer’ weather of February 1956, Big Pit had its best week since vesting day in 1947 when it produced a days record of 1,373 tons and a six-day week record of 7,113 tons of coal.

In 1955 out of a total manpower of 920 men, 362 of them were deployed to the coalfaces, the coalface figure increased to 507 in 1956, 534 in 1957 and 506 in 1958, in 1961 along with Garn and Kay’s Slope the total manpower was 1,491 men, with 603 of them on the coalfaces. In 1957 this colliery employed 87 youths under the age of 18 years which was, along with Six Bells Colliery, the highest figure in No.6 Area.

In 1961 this Complex was part of the No.6 Area’s, Blaenavon Group along with Blaenserchan and Beynon collieries. The total manpower for the Group was 2,579 men, while total coal production for the year was 527,500 tons. The Group Manager was E. Turner, while the Area Manager was Lister Walker. In May 1971 it was agreed to spend £100,000 on fully mechanizing the 30-inch thick Garw seam, twin-speed Gleithobel ploughs and hydraulic roof supports were installed.

In 1973 a new drift 1,860 feet long and dipping down at a gradient of between one in six to one in four was driven from near the washery and all coal was brought up via this drift. At that time the mine had a mineral take of about sixteen square miles stretching from near the outcrop of the Coalfield in the north to Varteg in the south. It had almost eight miles of roadways in use and 1.5 miles of conveyors. It was working two coalfaces in the Garw seam which was 750 feet below the surface and used 8 miles of underground roadways and 1.5 miles of conveyors.

In 1975 the NCB proposed closure for the colliery stating their concern over the possibility of hitting uncharted workings and shafts following the Lofthouse Colliery disaster. On the 21st of March 1973, an inrush of water trapped and drowned seven men at the Lofthouse Colliery in Yorkshire. Despite six days of rescue attempts only one body was ever recovered.

The Garw seam towards the outcrop was abandoned but other areas of coal were worked until closure in 1980. In 1975 the manpower distribution at the colliery was; at the coalface, 106 men, other worked underground, 180 men and on the surface 76 men. There were 249 men under 55 years of age, 64 men between 55 and 60 years and 49 men over 60 years of age. Prior to closure, the output per man shift on the coalface was 3.3 tonnes and overall for the colliery it was 1.1 tonnes.

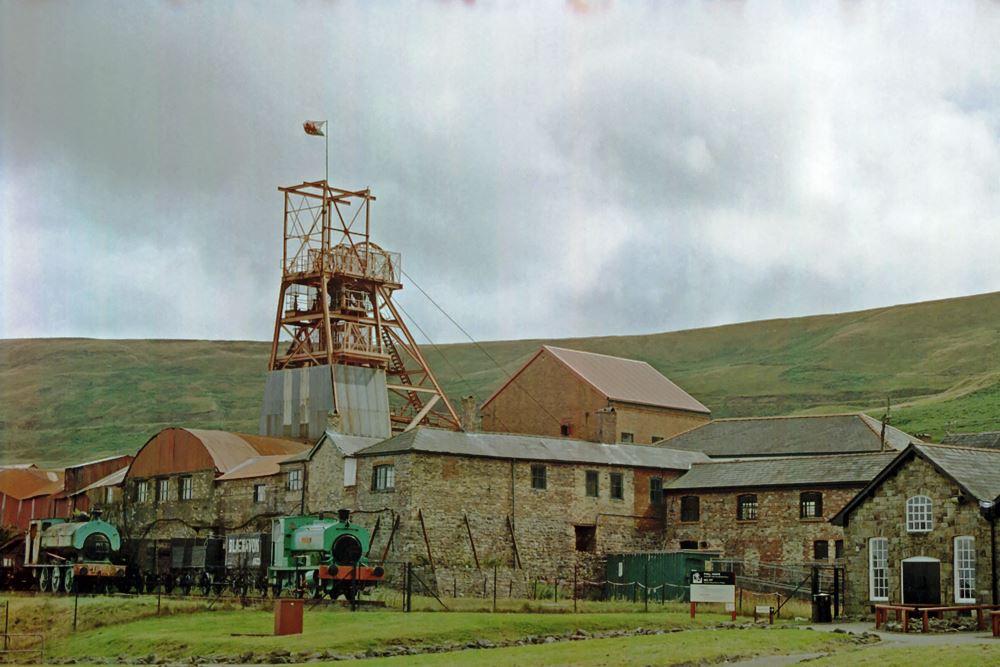

Big Pit was closed on April 4th 1980 and is now a mining museum.

Some of the fatal accidents at this mine and the associated workings:

- 18/03/1845, John Trembling: Fall of the roof.

- 29/01/1846, John Williams: Kicked by a horse.

- 27/04/1846, John Speak: Fall of a great weight of a stone.

- 31/05/1847 W. Pulling: Fall of rubbish and stone.

- 7/12/1847, John Jenkins: Fall of stone.

- 25/10/1852, John Howells, Age: 22: Collier: Fall of roof.

- 17/08/1853, John Powell, Age: 38: Collier: Fall of coal.

- 25/07/1854, William Bryant: Roof fall.

- 31/05/1855, David Thomas: Fall of large stone.

- 19/07/1855, William Prothero: Collier: Fall of large stone.

- 12/09/1861, Alfred Dash: Roof fall.

- 23/09/1861, David Harvey: Explosion of firedamp.

- 01/04/1862, Benjamin Downing, Age: 18: Collier: Heavy fall of coal.

- 28/03/1863, William Gunter, Age: 18: Miner: Heavy stone fell on his head from the roof.

- 28/03/1863, William Gunter: Fall of a large stone.

- 23/09/1863, William Vale, Age: 39: Miner: Fall of some substance from the side of the shaft.

- 21/04/1864, William Evans: Crushed in machinery.

- 2/07/1864, James Gregory, Age: 31: Miner: Fall of ground.

- 6/07/1864, Thomas Jones, James Parry: Fell down the shaft. 2 killed.

- 30/11/1864, William Green, Age: 15: Collier: Killed by fall.

- 8/02/1865, Herbert Williams, Age: 43: Overman: On 3rd Feb a tram underground was loaded with iron rails for use in the colliery and one of them projected too far and unfortunately touched the horse which caused him to take fright and run. The overman tried to stop it but was overwhelmed by horse and tram and received injuries which rendered amputation necessary. He died 9th.

- 21/03/1865, Evan Evans, Age: 13: Haulier: In bringing out of a stall and leading the horse he slipped up and the tram went over him and killed him.

- 4/08/1865, Boulton, Emmanuel Age: 20: Collier: By coal falling on his leg on the 3rd and it was thought necessary to amputate. He died.

- 5/01/1866, Benjamin Treasure, Age: 28: Miner: fall of roof.

- 19/02/1868 William Williams Age: 25: A stone fell from the roof

- 19/02/1868 William Penrew: Fall of a stone.

- 24/03/1868 David Jenkins, Age: 25: Collier: A piece of clod from the roof suddenly fell and killed him.

- 22/06/1868, Thomas Watts, Age: 52: Miner: Crushed by tram

- 3/03/1870, Robert Watkins, Age: 19: Collier: Run over by 6 full trams

- 10/03/1870, Henry Whiteley, Age: 77: Coupler: Fell in front of the loco and was killed instantly.

- 1/04/1871, Francis Williams, Age: 47: Engineman: Fall of roof

- 21/08/1872, Thomas Tovey, Age: 57: Pumpsman: Found crushed under pumping water wheel.

- 21/10/1872, Henry Jones Age: 13: Collier: Fall of the roof.

- 8/03/1873, Thomas Williams, Age: 38: Roadman: Sudden fall of stone.

- 23/04/1873, Joshua Morgan, Age: 51: Collier: Fall of clod and coal.

- 29/07/1875, Charles Davis, Age: 31: Haulier: Fall of clod

- 31/01/1876, J. Coles, Age: 22: Collier: Fall of the roof.

- 10/04/1877, William Struchcombe, Age: 29: Miner: Fall

- 9/04/1887, Edmund Harris Age: 49: Repairer: Ruptured a blood vessel when lifting a lump of rubbish into a tram.

- 30/01/1889, William Nash, Age: 38: Haulier: While clearing a fall with other men a stone from the roof fell upon him.

- 4/03/1889, Samuel Robins, Age: 26: Labourer: Blocked between trucks on railway siding near coke ovens.

- 22/02/1890, James Williams Age: 13: Coal trimmer: He fell about 9 feet from a plank which was in use about the screens and was picked up insensible. He died the same day.

- 13/07/1891, Thomas Finney, Age: 27: Collier: Fall of coal from the face.

- 24/08/1891, John O. Jones, Age: 16: Collier: Fall of the roof.

- 29/03/1894, John Williams Age: 29: Door boy: Fall of roof

- 24/06/1896, George Williams, Age: 43: Haulier: His arm was very badly smashed having been drawn between the rope and the pulley at the far end of the engine plane in consequence of his being knocked down by a horse which bolted. He died on 5th July from shock after an operation.

- 20/07/1896, James Williams, Age: 50: Collier: Fall of roof coal

- 30/09/1896, Job Probert, Age: 60: Collier: Fall of the roof at the face.

- 5/11/1896, George Luff, Age: 59: Collier: Fall of the roof.

- 03/12/1896, John Davies, Age: 36: Repairer: Fall of roof

- 13/05/1898, George Holden, Age: 10: Boy: Killed on the 13th May by a fall of fireclay in an old Patch belonging to the Blaenavon Iron Co. Ltd. where he was getting coal for home purposes. This death is more or less the result of the strike which caused much distress in the locality.

- 10/05/1899, William Davies, Age: 51: Labourer: Knocked down by the lash of haulage rope in consequence of a jerk occasioned by a roll of rope running and striking the trams.

- 18/01/1910, Thomas Vaughn, Age: 30: Loco latcher: While taking the workmen’s train to upper collieries he jumped off the loco to turn a pair of points and got run over.

- 22/01/1910, John Roberts: Killed by colliery locomotive.

- 1/04/1911, Charles H. Probert, Age: 14: Collier boy: Fall of roof

- 17/08/1911, David Williams, Age: 28: Hitcher: While in the cage pulling back a tram which had gone beyond the catch, he was wound up the shaft and thrown out of the cage by the tram catching a beam. The evidence as to the signals was contradictory.

- 20/11/1911, James Gunter, Age: 28: Collier: Fall of the roof at the working face.

- 12/12/1911, James Thomas, William Nash: Fall of stone 2 killed.

- 12/12/1911, William Williams, Age: 28: Haulier: Fall of the roof on the road

- 29/12/1911, Benjamin Richards, Age: 45: Collier: Died suddenly in stall.

- 4/05/1912, George Hartshorne, Age: 16: Collier boy: Fall of the side at the working face.

- 6/05/1912, John Kiely, Age: 36: Hitcher: While crossing the pit bottom when the cages were in motion, he was crushed by the descending cage.

- 6/06/1912, John Harris, Age: 31: Screensman: It is probable he fell in front of a wagon containing small coal, during some moving of wagons on sidings.

- 2/11/1912, Henry Edwards, Age: 14: Platelayers boy: Run over and killed on sidings near screens.

- 7/11/1912, Alfred Evans, Age: 37: Fireman: Fall of the side near the working face.

- 7/04/1913, Joseph Jenkins, Age: 43: Undermanager: William Bond, age 30, fireman, Underground fire – poisoned by carbon monoxide. 3 killed.

- 20/10/1913, George Henry Jenkins, Age: 40: Head hitcher: Explosion of gas caused by naked light.

- 21/01/1915, Alfred Hill: Roof fall.

- 21/01/1915, David Jones, Age: 61. Blacksmith: Knocked down by loco.

- 15/03/1916, James Williams: Roof fall.

- 13/07/1917, Edward Challenger: Roof fall.

- 30/08/1917, William Powell: Sucked into a chute.

- 2/01/1918, John Pugh: Trams ran wild.

- 11/12/1918, Thomas Allsopp: Injured by mandril.

- 2/09/1919, David Jones: Struck on the back by a stone.

- 31/10/1919, Isaac Morgan: Knocked down by trams.

- 21/06/1920, George Shoreland: Badly injured finger caused death.

- 1/09/1920, John Allen: Trucks ran wild.

- 14/05/1924, Richard Pritchard: Collier, crushed by stone.

- 19/08/1924, Harry Lewis: Found dead – cardiac syncope.

- 20/11/1924, Lewis Phillips: Collier: Fall of a large stone.

- 5/10/1927, John Reed: Crushed by trucks while picking coal.

- 14/05/1929, Henry Morgan, Age: 18: Collier’s assistant: Fall of clod.

- 19/08/1929, Arthur Jones: Roof fall.

- 12/12/1929, Henry Gulliford: Collier: Cut leg. Died Jan 13th 1930.

- 19/12/1929, Albert Morgan: Collier: Roof fall.

Some Statistics:

- 1889: Output: 106,000 ton

- 1894: Output: 123,572 tons

- 1899: Manpower: 753

- 1900: Manpower: 570.

- 1902: Manpower: 862

- 1903: Manpower: 969

- 1907: Manpower: 1,108

- 1908: Manpower: 1,132.

- 1910: Manpower: 1,096

- 1911: Manpower: 1,101

- 1912: Manpower: 1,050

- 1913: Manpower: 1,145.

- 1915: Manpower: 955.

- 1918: Manpower: 956.

- 1919: Manpower: 900.

- 1920: Manpower: 1,050

- 1923: Manpower: 1,232.

- 1924: Manpower: 1,313.

- 1925: Manpower: 897.

- 1926: Manpower: 791.

- 1927: Manpower: 810.

- 1928: Manpower: 606.

- 1929: Manpower: 602.

- 1930: Manpower: 672.

- 1932: Manpower: 700.

- 1933: Manpower: 805.

- 1934: Manpower: 577.

- 1935: Manpower: 2,200. Output: 600,000 tons with Garn & Kays.

- 1937: Manpower: 831.

- 1938: Manpower: 823.

- 1940: Manpower: 829.

- 1942: Manpower: 816.

- 1943: Manpower: 789.

- 1944: Manpower: 766.

- 1947: Manpower: 797. Output: 217,000 tons.

- 1948: Manpower: 825.

- 1949: Manpower: 875 with Garn & Kay’s.

- 1950: Manpower: 875.

- 1953: Manpower: 969. Output: 268,000 tons.

- 1954: Output: 213,115 tons.

- 1955: Manpower: 920. Output: 249,263 tons.

- 1956: Manpower: 1,064. Output: 255,654 tons.

- 1957: Manpower: 1,081. Output: 247,165 tons.

- 1958: Manpower: 1,060. Output: 226,875 tons.

- 1960: Manpower: 1,526. Output: 307,000 tons

- 1961: Manpower: 1,491. Output: 284,726 tons.

- 1962: Manpower: 1,059.

- 1964: Manpower: 875. Output: 217,000 tons.

- 1969: Manpower: 445.

- 1971: Manpower: 470.

- 1974: Manpower: 256. Output: 72,728 tonnes.

- 1979: Manpower: 237.

- 1980: Manpower: 237.