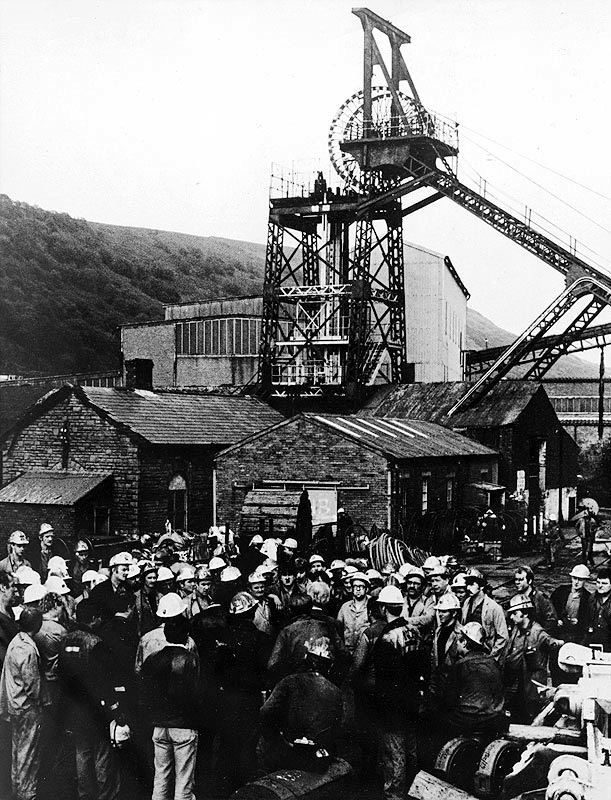

Roseheyworth Colliery 1984

In 1872 the South Wales Colliery Company leased land from Joseph and Crawshay Bailey for £60 per acre and sunk Roseheyworth Colliery. It was named after the wife of Major Lawrence Heyworth of Crosskeys and the London and South Wales Colliery Company.

The first coal was raised in 1873, one shaft was sunk to a depth of 758 feet, the downcast, with the upcast pit being the South Griffin No.3 Pit. This shaft was elliptical in shape 16 feet by 12 feet. The South Griffin No.2 Pit was used for pumping excess water up the shafts and was 16 feet in diameter. The South Griffin No.3 shaft was also 16 feet in diameter and was 243 yards deep to the Old Coal seam. The Four-Feet seam was found at a depth of 159.8 metres, the Nine-Feet seam at a depth of 2I1.1 metres and the Five-Feet/Gellideg seam at a depth of 252.5 metres. The Lower-Four-Feet seam had a section of up to 3.5 metres due to reverse faulting in parts of the mine but averaged out to 1.8 metres. The Upper-Nine-Feet seam had an average section of 1 metre, the Lower-Seven-Feet seam a section of 0.75 metres, and the Garw seam an average section of 0.77 metres.

On the 19th December 1876 an explosion killed 15 miners. The newspaper report of this can be found here.

On the 27th of June 1888 William Blackie died under a fall of roof at this colliery – he was only 12 years of age and one of the many to die that way in south Wales.

In 1888 the working colliery was leased to Lancaster, Spier & Co and later Lancaster’s Steam Coal Collieries Limited. This company was not a member of the Monmouthshire and South Wales Coal Owners Association. In 1888 it was managed by D. Lewis who was still manager in 1896. In 1908 the manager was T.J. Williams and in 1918 it was B.P. Thomas. In 1913, along with Cwmtillery, it employed 2,986 men producing coking, house, manufacturing and steam coals. At that time Lancaster’s advertised:

Lancaster’s Steam Coal Collieries Ltd London, Cardiff and Newport Proprietors and Shippers of- Russell’s New Black Vein Steam Coal Lancaster’s Navigation Steam Coal Russell’s Foundry and Furnace Coke. Elled House Coal Washed Nuts, Beans, Peas & Duff.

Used largely by the principal Railways in Great Britain, Ireland, France, Egypt, Italy and South America, also by the leading Steamship Companies, and at Foreign Depots for Bunkering purposes. Shipping Ports: Newport, Cardiff, Bristol, London, Southampton and Birkenhead

On Nationalisation in 1947, Roseheyworth Colliery was placed in the National Coal Board’s, South Western Division’s, No.6 (Monmouthshire) Area, and at that time employed 142 men on the surface and 607 men underground working the Upper and Lower Black Veins (Nine-Feet), the manager now being W.J. Harris. The Top Black Vein seam was worked by filling onto conveyors on the coalfaces but the Lower Black Vein was still worked on the old heading and stall system. The same seams were being worked in 1954 with manpower then being 143 men on the surface and 647 men underground. The manager was E.J. Edwards. In 1956 out of the total colliery manpower of 789 men, 336 of them worked at the coalfaces.

Pit Bottom

The colliery was threatened with closure in 1947. With a manpower of 700, it could only achieve a pretty low annual output of 113,000 tons of coal. However, following consultations with the men it was agreed to install a new surface plant, including modernizing the coal preparation plant, simultaneous decking of the trams in the cages at the pit bottom, and electric haulages were to be installed instead of the inefficient compressed air ones, new tunnels were driven to improve the delivery of supplies and to get the coal out quicker, dust suppression methods were brought in and coal cutting was mechanised in the form of a Meco Moore coal cutter. These improvements started to pay off and in 1949 the pit raised 130,000 tons of coal with a manpower of 730 men and an output per manshift of 16.4 cwts.

The late 1950s was a time of re-organisation within the National Coal Board in South Wales, economic realities had caught up with the mining industry and in the Monmouthshire section of the Coalfield two major programmes were embarked upon; one concerned the Glyn Valley and the Hafodyrynys New Mine project, the other was a few miles up the road at Abertillery.

The Roseheyworth Colliery and the Cwmtillery Colliery were 2.5 miles apart by surface road but only 1,200 yards by underground roadway. They were merged and a new surface layout and washer was installed at Roseheyworth, a new drift was made to bring the output of both collieries to the surface at Roseheyworth. This drift was opened 100 yards to the north of the Roseheyworth downcast shaft and was driven on 14 feet arches, it was 1,070 yards long with a dip of 1 in 5 and designed to intersect all the workable coal seams down to the Garw seam. The drift was then continued for 670 yards at 1 in 22 into the Garw seam workings at Cwmtillery. It had a maximum capacity of 400 tonnes of coal per hour. This drift also acted as an additional ventilation intake and the shafts at South Griffin, which up to then aided the ventilation of Roseheyworth were abandoned. The collieries involved in the project (Roseheyworth and Cwmtillery) were renamed Abertillery New Mine.

In 1961 the colliery was in the No.6 (Monmouthshire) Area’s, Abertillery Group, along with Hafodyrynys, Glyntillery, Tirpentwys and Cwmtillery Collieries. The total manpower for the Group was 3,147 men, while the coal production for that year was 945,000 tons, making it one of the largest Groups in the South Wales Coalfield in terms of both production and manpower. The Group Manager was J.A. Moxham, and the Area Manager was Lister Walker. The scheme cost around £3 million invested to release an expected 12,000,000 tons of coal and extend the life of the New Mine by 25 years. and brought about strange arrangements, in 1979 the LB7 coalface in the

The Roseheyworth section of the mine was manned on one shift by Roseheyworth men and on the other shift by Cwmtillery men who travelled through different shafts. The official date for the merger was the 21st of November 1960.

In January 1967 the NCB spent £150,000 on a remote push-button control and TV scanners system to monitor the three miles of underground conveyors. This reduced the need for conveyor attendants by 44 men.

In 1969 A.E. Handley was the manager and the New Mine employed 1,162 men working underground in the Three-quarter, Big Vein, Meadow Vein and Garw seams with 194 men working at the surface of the mine. It was producing 15,000 tons of coal per week from eleven longwall coalfaces in three different seams eight of which were in the 29-inch thick Garw seam. Mr. Handley was still the manager in 1972 while in 1975 M.V. Edwards was the manager. Ray Young became the manager in 1976 and around this time the New Mine used 35 miles of underground road with 11 miles of them being equipped with conveyor belts and employed 1,036 men. There were 12 miles of haulage roads using 32 haulages.

The normal method of working this seam at that time was to undercut the coal and hand fill onto bottom-loading conveyor belts. They were usually double units of 100 yards on each side of the gate road. In May 1971 a trial was carried out by installing Gleithobel ploughs and hydraulic roof supports on one of the Garw seam coalfaces. This coalface, the G36, then produced 300 tons of coal a week more than the hand-filled ones and it was decided to equip all future faces with this equipment. There then followed a gradual reduction in manpower from 1,040/191 in 1970 to 881/155 in 1972. Later the output from Blaenserchan Colliery was brought through a 360 feet link-up underground roadway to Roseheyworth Colliery, and by 1967 the main trunk conveyor had reached a length of 3 miles.

Two of the shafts at Cwmtillery were filled in in the 1970s, the No.3 in 1970 and the No.2 in 1975, the No.1 was used as the upcast ventilation shaft for the New Mine. The Garw seam, at 30 inches high was being worked by a Gleithobel plough filling onto an armoured conveyor. The armoured face conveyor travelled at 145 feet per minute and the plough at 72 feet per minute so that the coal was rapidly taken away. Each cut was only two inches but on the 182 yard long face with a four-foot thick seam, over 450 tons could be produced each shift. Roof supports were hydraulically operated two-legged self-advancing ones.

In the 1970s, as well as the Garw seam, coal was still being cut from the Three-Quarter and Black Vein seams in the New Mine, with ranging drum shearers used to cut the coal. The reserves in these seams were almost worked out. From the coalfaces, the coal was filled onto trunk conveyors which carried the coal, via the new drift tunnel all the way into the coal preparation plant at Roseheyworth then away to the markets. At the Roseheyworth end, the supplies were taken down the shaft for the Garw and Black Veins while the Cwmtillery shaft fed the Three-Quarter seam.

More investment was made at the pit in 1977 with the longest underground man-riding system in the South Wales Coalfield installed at Cwmtillery Colliery to transport men and materials a distance of 3,000 metres at a cost of £100,000. This manrider, which consisted of seven carriages, cut travelling time down to 25% over the previous and allowed extra time at the coalfaces.

More investment was made at the pit in 1977 with the longest underground man-riding system in the South Wales Coalfield installed at Cwmtillery Colliery to transport men and materials a distance of 3,000 metres at a cost of £100,000. This manrider, which consisted of seven carriages, cut travelling time down to 25% over the previous and allowed extra time at the coalfaces.

At a meeting of the South Wales Institute of Engineers on the 24thof October 1984 Mr. V.D. Savage, reflecting on Abertillery New Mine, stated that this new mine was an “immediate success with output peaking at 17,000 tonnes saleable per week for manpower of around 1,500 men.” He continued to state that; “For the next 14 years, the good performances of the complex resulted in healthy annual profits, however, with the decreasing reserves of coal … by 1976 output had fallen to less than 7,000 tonnes per week and the manpower of about a thousand was scattered throughout the overextended mine.”

In 1974 the NCB reported that another major investment programme was required to produce the projected output of coking coals for the 1980s and to ensure the continuity of supplies into the 1990s. In 1974 exploratory boring at Blaenserchan Colliery proved that the Garw seam was 2 feet 9 inches to 3 feet thick over a large area which previously was thought to be too thin to work. The total reserves proved in this seam were 3.5 million tons, which equals the remaining reserves of the seam at Abertillery. The scheme involved the development of those reserves –connecting the coal transport systems to that of Abertillery by driving 1,800 yards of underground roadways. It was estimated that for a cost of £1.1 million, the two pits would yield 480,000 tons of coal annually with an output per manshift of 35.8 cwts.

In 1981 the NCB intensified the pressure to close the Cwmtillery end of the colliery, stating that 5 years ago it had made a profit, 4 years ago it lost £600,000 and in 1980 it had a loss of £4.5 million. The NCB wanted to close the G47 coalface and transfer men to development work in the Roseheyworth side of the mine. At that time the New Mine was working the Elled seam with a coalface length of 165 metres, and a thickness of 95 cms. The Big Vein with a coalface length of 80 metres and a thickness of 1.7 metres. The Lower-Nine-Feet (Old Coal) seam with a coalface length of 160 metres and a thickness of 1.42 metres. The Garw seam had a coalface length of 200 metres and a thickness of 70 cm. The Cwmtillery section of the New Mine was closed on the 21st of November 1982 with only the ventilation fan retained to supply the Roseheyworth side with air.

The mood had changed since the advent of a Conservative Government headed by Margaret Thatcher in 1979, there was no more optimism, only gloom. As part of the preparation for the struggle ahead, in 1983 the NCB announced that this colliery was losing £25.80 per tonne of coal produced. The colliery manpower at that time was 448.

Following the 1984/5 Miners Strike, Roseheyworth Colliery regained 80% of normal production within a month but found that the National Coal Board’s market at Llanwern Steel Works had shrunk from 26,000 tonnes a week to just 15,000 tonnes a week due to foreign imports. Roseheyworth Colliery continued to supply 4,000 tonnes of coal each week to Llanwern Steel Works but rumours started to fly around that the now British Coal wanted to close the Mine. These rumours were denied by the Area Director in September of that year, and something like the football managers vote of confidence, a little later the mine closed. The Area Executive Council Meeting Minutes of the NUM of the 8 of October 1985 state that the men had agreed to the closure of the colliery. This colliery was closed on the 9th of October 1985 due to extremely poor results.

Generally, based on the Nine-Feet seam, this colliery produced 301A Prime Coking Coals for use as foundry and blast furnace cokes. They had a low ash content of around 5% to 9%, and a low sulphur content of around 0.6% to 1.5%.

Some Statistics:

- 1894: Output: 153,081 tons

- 1896: Manpower: 1,625 with Cwmtillery.

- 1899: Manpower: 1,589 with Cwmtillery.

- 1900: Manpower: 1,820 with Cwmtillery.

- 1901: Manpower: 1,865 with Cwmtillery.

- 1902: Manpower: 1,970 with Cwmtillery.

- 1903: Manpower: 1,917 with Cwmtillery.

- 1905: Manpower: 2,066 with Cwmtillery.

- 1908: Manpower: 2,654 with Cwmtillery.

- 1909: Manpower: 2,664 with Cwmtillery.

- 1910: Manpower: 2,671 with Cwmtillery.

- 1911: Manpower: 2,727 with Cwmtillery.

- 1912: Manpower: 2,890 with Cwmtillery.

- 1913: Manpower 2,986 with Cwmtillery.

- 1918: Manpower: 2,760 with Cwmtillery.

- 1920: Manpower: 2,605 with Cwmtillery.

- 1923: Manpower: 1,081.

- 1924: Manpower: 1,152.

- 1927: Manpower: 952.

- 1928: Manpower: 748.

- 1930: Manpower: 750.

- 1933: Manpower: 114.

- 1934: Manpower: 330.

- 1935: Manpower: 615. Output: 200,000 tons.

- 1938: Manpower: 804.

- 1940: Manpower: 780.

- 1945: Manpower: 754.

- 1947: Manpower: 749.

- 1948: Manpower: 677. Output: 155,000 tons.

- 1949: Manpower: 737. Output: 130,000 tons.

- 1950: Manpower: 739.

- 1954: Manpower: Output189,000 tons.

- 1955: Manpower: 818. Output: 191,625 tons.

- 1956: Manpower: 789. Output: 159,501 tons.

- 1957: Manpower: 695. Output: 160,466 tons.

- 1958: Manpower: 654. Output: 89,518 tons.

- 1960: Manpower: 642. Output: 129,000 tons.

- 1962: Manpower: 414.

- 1974: Manpower: 1,086.

- 1978: Manpower: 1,073. Output: 270,631 tons.

- 1979: Manpower: 896. Output: 204,000 tons.

- 1981: Manpower: 768.

- 1984: Manpower: 448.

THE COAL SEAMS AT ROSEHEYWORTH

FOUR-FEET: A composite seam consisting of the Upper and Lower Four-Feet seams and generally called the Big Vein. It has been extensively worked.. At Abertillery New Mine it was 3.5 metres thick due to abnormal geology. The gap between the Lower-Four-Feet seam and the Upper-Six-Feet seam was 15.2 metres at Abertillery New Mine.

SIX-FEET: This seam consists of two close-lying coals. It has been extensively worked. The Upper-Six-Feet (or Three-Quarter in the Ebbw Valley’s), At Abertillery New Mine the section was coal 0.13 metres, dirt 0.13 metres, coal 0.45 metres.

RED VEIN: This seam is absent throughout the area.

NINE-FEET SEAM: The Upper-Nine-Feet is the thinner of the two leaves and is absent altogether in some parts. In the Ebbw Valley’s it was called the Top or Upper Black at Abertillery New Mine. The Lower-Nine-Feet was one of the thickest seams in the area and was extensively worked throughout the Valley. It was called the Bydelog or Black Vein and averaged 1.2 metres in thickness although it was subject to washouts in the Ebbw Fach Valley. The gap between the Lower-Nine-Feet seam and the Bute seam is generally between 7 metres and 12 metres.

BUTE SEAM: was too thin to work.

AMMAN RIDER: This seam is of poor quality and has not been worked. Its average thickness is 0.3 metres to 0.4 metres. The gap between the Amman Rider seam and the Yard seam is between 3 metres and 5 metres in this area.

YARD/SEVEN-FEET: This composite seam is also called the Meadow Vein. The Yard seam part consisted of two leaves of coal near the northern outcrop totalling 1.2 metres, and was known in this area as the Upper Meadow Vein, it shows 0.8 metres in thickness in this area.. Between the Yard and the Upper-Seven-Feet seam there is a gap of 7 metres at its northern outcrop but this gap reduces to only a few centimetres by time you reach the south of Abertillery. The Upper-Seven-Feet seam at Abertillery New Mine is 0.75 metres in thickness. The gap between the Lower-Seven-Feet seam and the Five-Feet/Gellideg seam was generally between 6 metres and 13 metres.

FIVE-FEET/GELLIDEG: This seam was usually called the Old Coal seam and was extensively mined. Consisting of three coals; the Gellideg, the Lower Five-Feet and the Upper-Five-Feet. The section averaged; coal 0.63 metres, clod 0.2 metres, coal 0.1 metres, dirt 0.6 metres, coal 07. Metres, dirt 0.4 metres, coal 0.7 metres. The gap between the Gellideg seam and the Garw seam varies in thickness widely from between 11 metres and 40 metres. GARW SEAM: It has been deep mined in the Abertillery area at Abertillery New Mine it showed a thickness of 0.7 metres.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page