Fochriw, near Rhymney (SO 1032 0516)

The original pit was sunk in 1853 to a depth of 390 yards to the Four-Feet seam at a cost of £83,000 by the Dowlais Iron Company to feed the Dowlais Iron Works. This pit was divided in two by brattice cloth to serve as both the upcast and downcast ventilation shafts. The practice of having only one shaft meant that in the event of an emergency there was only one means of escape, and if that shaft was damaged, there was no escape.

In May 1852 at the Middle Duffryn Pit near Aberdare, an explosion of methane gas killed fifty-five miners with another nine being killed when the staging in the shaft collapsed during their escape. This and other incidents were responsible for a law that made a second shaft compulsory to aid ventilation and provide escape alternatives. The law came into being in 1862 but the Dowlais Iron Company were already sinking the two new pits by then. The Fochriw website informs us that ‘The Star’ newspaper announced that the decision to sink the pits had been arrived at in January 1857 and by the October of that year the shafts were down forty yards and the permanent winding gear had been installed. Then some confusion with this newspaper when it reported in December 1859 that the pits were in operation and that they had ‘commenced’ five years previously, that is 1854. To confuse the sinkings a little more, the NCB records give the dates as:

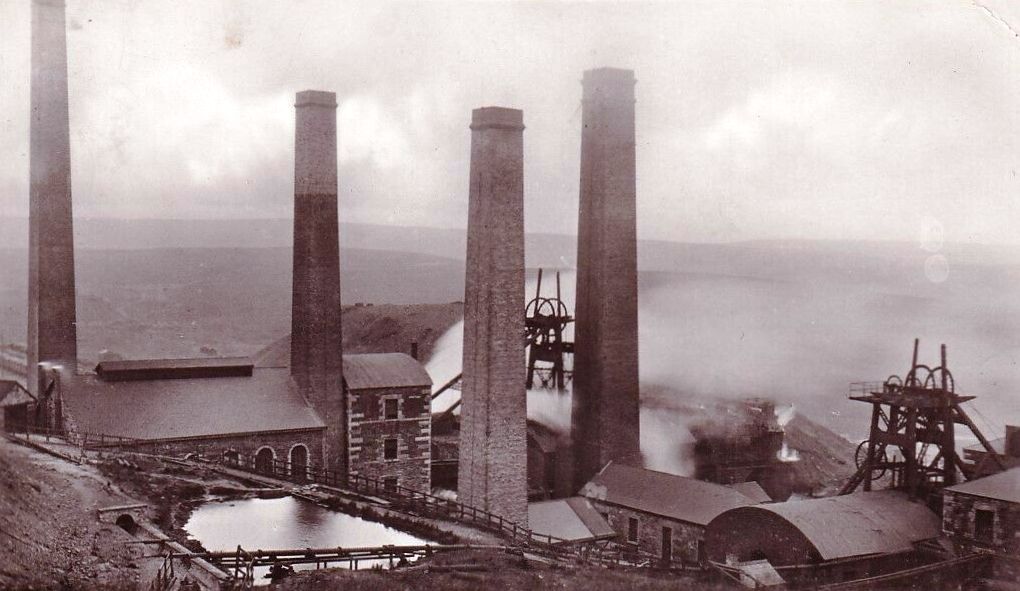

The company sank the No.1 (North) upcast ventilation Pit in 1863, which was sunk to a depth of 443 yards and the No.2 (South) downcast ventilation Pit which was completed in 1866 to 433 yards. Both shafts were elliptical in shape measuring 22 feet by 12 feet. The shafts were 44 yards apart.

Coal production was carried out through both the shafts but on the dayshift only, the nightshift was used for maintenance and roadway repairs. The downcast shaft was used to wind from the Rhas Las and Red Veins and the upcast shaft from the Upper-Four-Feet and Big Veins. The Rhas Las (Upper-Nine-Feet) was the main seam to be worked in the early days. It was worked on the old longwall system where the stalls were 11 yards apart and the whole of the seam was removed.

On the 8th of January 1870 the rope detached itself from the winding engine drum and along with the cages fell down the No.1 Shaft. Five men were killed; Absalom Andrews aged 22 years, a hitcher, as was S. Rees aged 47 years and H. Thomas aged 39 years. The others killed were M. Jones aged 48 years (overman) and D. Davies aged 47 years (labourer).

In October 1873 management was not averse to using the law for a little bit of blackmail. A dispute arose and the men refused to go to work. Management then summoned seventeen of the ‘ringleaders’ to court over breach of contract by walking out. When the day of the hearing arrived they withdrew the case as it had been ‘amicably settled’.

In the 1880’s it had a steam-driven Cornish high pressure condensing beam engine pumping engine which had cylinders 85 inches in diameter and with a 9 feet stroke. The winding engine for the No.2 Pit had a pair of vertical high-pressure engines with 36-inch cylinders with a 7 feet stroke. The carriages were double-decked. Ventilation for the No.2 Pit in 1881 was provided by a Schiele type fan which had a fifteen feet diameter.

In September 1909, Ernest Joyce, aged 34 years and a collier originally from Bristol was killed under a roof fall in the Red Vein. The men in the No.2 Pit requested half a shift off work to attend the funeral but this was refused. They then turned up for work as normal and then walked out for the whole shift.

In 1878 the manager was T. Bevan, and in 1896 the No.1 Pit employed 667 men underground and 99 men on the surface and the No.2 Pit 656 men underground and 99 men on the surface, the manager for both pits was Thomas Bevan.

On the 4th of June 1902, eight men lost their lives in an explosion, caused by the use of a naked light. The full report on this can be found here.

Ownership changed to Guest and Company in 1901, and then to Guest, Keen and Nettlefolds Limited in 1902 whose, sale agents were P.C. Cook, Dock Chambers, Cardiff. GKN was a member of the Monmouthshire and South Wales Coal Owners Association. The manager in 1908 and 1919 was John Bevan.

In 1910 The No.1 Pit was working the Two-Feet-Nine and Upper-Four-Feet seams producing 1,900 tons of coal per week while the No.2 Pit was working the Big, Red and Rhas Las seams and produced 3,900 tons of coal per week.

This colliery was served by the Brecon and Merthyr Railway and produced steam coals, employing 709 men in the No.1 Pit, and 1,250 men in the No.2 Pit in 1913. The manager was now John Bevan.

The coals of this colliery were generally classed as type 203 Coking Steam Coal, low volatile, weak to medium caking, with the ash content around 5%. It was used for foundry and blast furnace coke, and for steam raising. The Elled, Upper-Four-Feet, Lower-Six-Feet, Rhas Las, Red, Little and Lower Two-Feet seams were abandoned on closure in June 1924.

Just some of those that died at this mine;

- 24/2/1893, Morgan Edwards, aged 40, repairer, roof fall.

- 20/10/1893, David Jones, aged 47, repairer in No.1, roof fall.

- 10/4/1894, John Pearce, aged 31, collier in No.1, run over by trams.

- 13/4/1894, John Lewis, aged 15, engine boy in No.2, scalded.

- 13/4/1894, William East, aged 31, collier in No.1, roof fall.

- 25/1/1895, David Prosser, aged 14, collier boy in No.2, run over by trams.

- 5/3/1895, Griffith Hughes, aged 12, collier boy in No.1, roof fall.

- 14/11/1895, John Jones, aged 24, collier in No.2, roof fall.

- 30/6/1896, Edward Parson, aged 39, rider No.2, crushed by trams.

- 26/7/1897, David Price, aged 13, collier boy in No.2, roof fall.

- 8/1/1901, Elias Evans aged 19 years was killed in a haulage accident.

- 12/1/1901, James H. Jones aged 29, Thomas Lewis aged 17 years and three horses were all run over by trams and killed.

- 29/1/1901, William Davies aged 57 years was run over by trams.

- 30/1/1901, John Swancott aged 32 years was run over by trams.

- 27/2/1901, Daniel Lewis aged 38 years was run over by trams.

- 4/6/1902, eight men lost their lives in an explosion, caused by the use of a naked light.

- 9/1909, Ernest Joyce, aged 34 years and a collier, roof fall in the Red Vein.

- 14/2/1910, Soloman Williams, aged 53, collier, roof fall.

- 13/5/1911, D.G. Gwyther, aged 18, labourer, roof fall.

- 31/5/1911, Owen Jones, aged 59, repairer, roof fall.

- 28/11/1911, Charles Conway, aged 28, hitcher, shaft incident.

- 20/10/1912, Evan Evans, aged 31, repairer No.2, fell down the shaft.

- 19/2/1913, Edwin Morris, aged 39, hitcher in No.1, fell down the shaft.

- 3/4/1913, William Thomas, aged 50, repairer in No.1, roof fall.

- 19/4/1913, William Prosser, aged 49, collier, roof fall.

- 14/2/1914, James Morgan, aged 35, haulier in No.1, roof fall.

- 2/3/1914, Richard Prosser, aged 28, haulier, run over by trams.

Some Statistics:

- 1887: Output: 259,926 tons.

- 1889: Output: 335,988 tons

- 1893: Output: 285,640 tons.

- 1894: Output: 313,974 tons.

- 1895: Output: 314,614 tons.

- 1896: Manpower: 1,521. Output: 306,573 tons.

- 1899: Manpower: No.1: 717. No.2: 714.

- 1900: Manpower: No.1: 618. No.2: 783.

- 1901: Manpower: No.1: 655. No.2: 819.

- 1902: Manpower: 1,548

- 1903: Manpower: 1,571. Output: 342,372 tons.

- 1905: Manpower: No.1: 559. No.2 1,016.

- 1907: Manpower: 1,508.

- 1908: Manpower: 1,485.

- 1909: Manpower: 1,097. Output: 298,283 tons.

- 1910: Manpower 1,720.

- 1911: Manpower: 1,720.

- 1912: Manpower: 1,796.

- 1913: Manpower: 1,959. Output: 380,500 tons.

- 1914: Manpower: 1,964.

- 1915: Manpower: 2,000.

- 1916: Manpower: 1,850. No.1: 650. No.2: 1,200.

- 1917: Manpower: 1,790.

- 1918: Manpower: 1,780. Output: 304,690 tons.

- 1919: Manpower: 1,780. No.1: 560. No.2: 1,220.

- 1920: Manpower: 1,780.

- 1922: Manpower: 1,705.

- 1923: Manpower: 2,009.

- 1924: Manpower: 1,975.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page