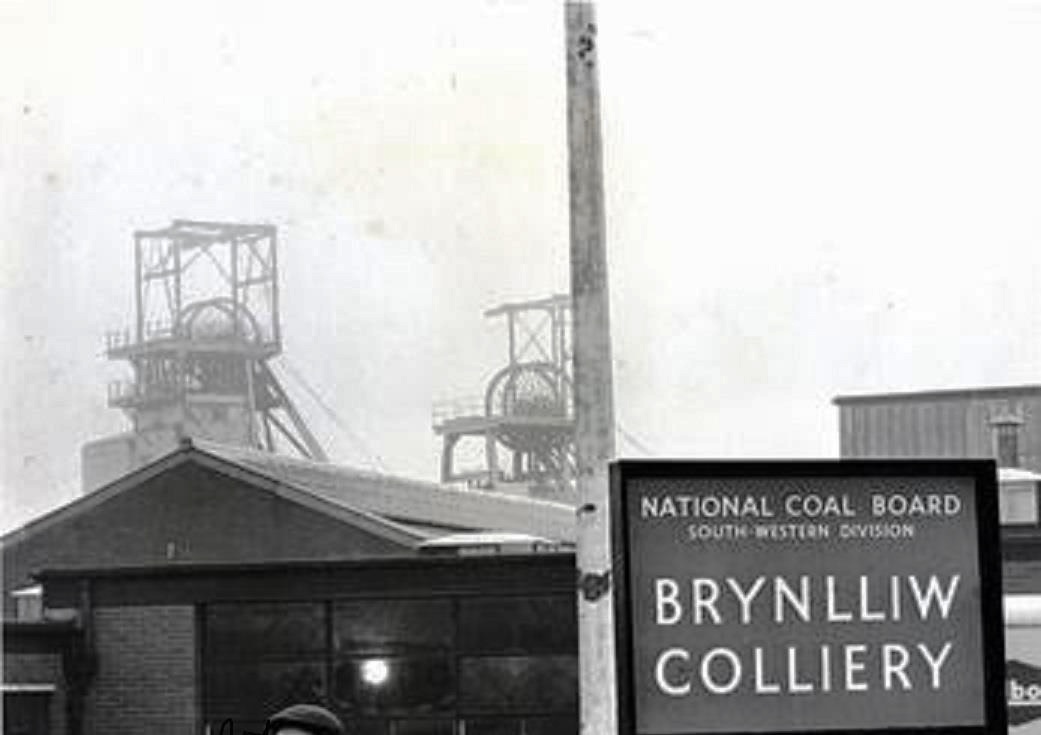

This mine was located between Gorseinon and Pontardulais approximately seven miles north-west of Swansea. It was sunk between 1903 and 1905 by Thomas Williams (Llangennech) Limited to the Swansea Four-Feet seam at a depth of 340 yards. The South Wales Miners Federation Lodge at this colliery was formed in June 1909.

In April 1910 the owners were granted an arrest warrant against the colliery manager, J.R. Watkins, who they claimed had falsified the books by entering wages for men who had not been working at that time or had not achieved the payments stated. Mr. Watkins was not to be found at that time.

The Four-Feet seam was found to be only 24” thick so in 1914 developments were made into the Swansea Five-Feet seam which averaged 34 inches. At this time it employed 281 men, with the manager being J. Beynon.

In June 1914 the men complained that their house coal was mainly made up of small coal which could not be burned. The owners ignored this complaint so the men issued a fortnight’s notice to go on strike along with the other pits of the company; Morlais, Talyclyn, Llangennech and Grovesend. Other issues were also brought into the dispute by both sides including the price list for the new Five-Feet seam workings and the employment of non-unionists at the mines. The mass meeting of the men was held at Haggars Bioscope Palace, Pontardulais.

The big boys of the South Wales Miners Federation were sent in on the 10th of September to talk to the men about a settlement, leaders such as James Winstone and Vernon Hartshorn, but they had little effect and the meeting was abandoned due to disorder. After twenty-two weeks on strike, it was in November 1914 that the men voted to return to work on roughly the same terms as before the strike.

Mr. Beynon was still the manager in 1916 when it employed 167 men. In 1918 it only employed 89 men underground and 46 men on the surface. The manager was still John Beynon who was still there in 1932 when this pit employed eight men.

On the 16th February 1912, Daniel Morgan, Age: 21 and a collier, died under a fall of the roof at the coal face. A stone fell crop with the coal, killing him instantly. Three props were discharged with stone. Then on the 18th July 1913, Richard Edward Lewis, Age: 24: Trammer, was crushed by runaway trams. Just two of the fatalities at this mine.

The difficult geology encountered at this pit, coupled with the depression in the coal trade of 1925 brought about the closure of the colliery in 1925 with it being abandoned in 1927. The Company was associated with the Monmouthshire and South Wales Coal Owners Association.

On the Nationalisation of the nation’s coal mines in 1947, there were only three men employed at the surface of Brynlliw engaged in pumping operations. In 1954 the National Coal Board decided to carry out a major reconstruction programme at Brynlliw costing £4.8 million. Amongst other works they installed skip winding in the No.2 shaft, modernised the No.1 shaft for materials and manriding and deepened them both by 35 yards to the Six-Feet seam. New underground roadways for locomotive use were driven with the main trunk belt being 42 inches wide, 1,400 metres long and driven by a huge 400 h.p. motor. On the surface, a new coal preparation plant capable of washing 250 tons of coal an hour was constructed plus new pithead baths.

The No.1 pit was then 335 metres deep and had a diameter of 13 feet 6 inches, and the No.2 pit was 350 metres deep with the same diameter. The No.1 winding engine had an h.p. of 1,350 and the No.2 winding engine had an h.p. of 1,100 and could wind 48 men at a time. It was equipped with skip winding at 4 tons a wind giving an output maximum of 240 tons per hour.

At that time the colliery was in the South Western Division’s Area No.1, Group No.2 (Morlais) together with Garngoch No.3, Morlais and Mountain collieries. In 1961 this Group employed a total of 1,987 men and produced 435,477 tons of coal. In 1957 the NCB reported that there were 44 million tons of coal available to the colliery which was to be mined at a rate of 750,000 tons a year from the Swansea Four-Feet, Five-Feet, Six-Feet, Three-Feet and Two-Feet seams. The take for the colliery amounted to twelve square miles but was affected by six major geological faults which moved the coal seams between 46 to 306 metres.

The Three-Feet seam had reasonable conditions but was thin, the Six-Feet seam had poor roof conditions and the maximum length of coalface that could be opened was restricted to 109 metres. Production re-commenced in 1961 in the Six-Feet seam which varied tremendously in thickness from 36 to 85”, because of the nature of the seam the method of coalface working chosen was room and pillar.

At 11.30 am on the 10th of May 1963 on the S2 Plough Coalface, James Webber aged 50 years, Bryn Griffiths aged 54 years, Malcolm Thomas aged 26 and Antonio Era aged 39 years all died under the same fall of the roof with another three miners were injured.

In 1963 the NCB reported that; Brynlliw…The scheme for re-opening and reorganisation of Brynlliw was completed in 1962 and full output of 468,000 tons is expected to be achieved in 1964/65. The 1963 annual review raises the stage 2 estimates of overall productivity and profitability to 49.1 cwts and 39/2d per ton. respectively. The higher o.m.s was actually exceeded in 1962. Recent results have been adversely affected by poor roof conditions.

Present manpower is about 150 below the Divisions estimate of requirements and most of this increase will need to be obtained by inter-divisional or long-distance transfers for whom the division has been authorised to purchase up to 77 caravans as a temporary measure. I.D.T.s are now occupying 42 of these and the division will not be proceeding with the remaining 35. The full housing programme now planned should enable the colliery to obtain the extra men required and stabilise manpower in the long term.

The investment in this colliery started to pay off and in January of 1964, the colliery was attaining output per manshift figures of 50 hundredweights, one of the highest in the South Wales Coalfield. In 1968 the pit was working both the Three-Feet and Six-Feet seams by the longwall method of coal extraction, the classification of its coals had now changed from steam to anthracite. It produced over 300,000 tons of coal in that year.

In September 1973 the NCB at South Wales level informed the NUM that they wished to close this colliery with losses running at -£12.37 per ton of coal produced, however, the national NCB deferred closure and reprieved the pit in April 1975. By 1975 performances had been improved by shortening the coalfaces from 180 yards to 90 yards which facilitated better roof control. Output per manshift increased to 46.4 hundredweights which was better that the national average and twice that of the south Wales Area.

In 1976 Brynlliw had been connected under the River Loughor with Morlais Colliery by a 309 metre long roadway that dipped towards Brynlliw at a gradient of 1 in 3.5 and the two pits merged in 1977. All production was directed to the Brynlliw shafts with a 200 tonne bunker installed underground in the case of winding delays.

It was in 1976 that the NCB in South Wales issued its plan for the future in which Brynlliw/Morlais was one of three groupings for the power station markets. The others were Blaenant and Taff Merthyr/Deep Navigation/Merthyr Vale. The schemes were intended to increase output and efficiency, provide coal preparation and blending facilities to ensure an 18% ash product, and install surface bunkering arrangements incorporating rapid loading facilities for M-G-R trains. It was estimated to cost £250,000 and give an estimated output of 290,000 tons with an output per manshift of 40.6 cwts.

In the mid 1970s production at the colliery was concentrated on the Swansea Three-Feet and Six-Feet seams at the Brynlliw end and in the Swansea Five-Feet seam at Morlais. At that time there were 13.5 miles of underground roadways and nearly four miles of conveyors. In 1979 the output per manshift at the coalface was 5.4 tonnes and overall for the colliery it was 1.5 tonnes. The TO9 coalface was the best performing coalface in the South Wales Coalfield in the under 90 centimetres thick group, with a daily tonnage of 333.

In 1981 workings were in the Five-Feet seam which had a section of 62”, the Six-Feet seam which had a section of 77”, and the Three-Feet seam which had a section of 29”. Coalface length varied between 90 metres and 192 metres, with the Five-Feet and Six-Feet seams being cut by ranging drum shearers, and the Three-Feet seam by Gleithobel plough. All coalface supports were the self-advancing types. The saleable yield of clean coal was 80% of total production. Coalface output per manshift was planned at 6.18 tonnes, and overall output per manshift at 1.43 tonnes. Manpower deployment was; coalface 193, development 55, others underground 367, surface 48. The manager at that time was R. Thomas. The coalfaces in the Six-Feet seam were prefixed with an “S” with the S8 expected to advance 1.3 metres per day on a single coaling shift and producing 400 tonnes a day. It was to close in September 1981 and be replaced by the S9 coalface which was expected to advance 2 metres per day on single shift coaling and produce 400 tonnes of coal per day. This face had a life of 660 metres. The S29 coalface was advancing at a rate of 1 metre per day producing 300 tonnes of coal and had a life of 650 metres in February 1981. The coalfaces in the Three-Feet seam were prefixed with a “T” with the T10 coalface advancing at a rate of 2 metres per day on double coaling shifts and giving an output of 400 tonnes. It was expected to close in October 1981 and be replaced by the T12 coalface which had a life expectancy of 1,150 metres. In April 1981 there was no productive coalface at Brynlliw when the S28 was stopped for three weeks to transfer the equipment to the S29. At the same time the S8 at the Morlais end was having problems with excess water at the coalface and atrocious working conditions. At meetings held on the 13th and 14th of April 1981, the men at the Morlais end accepted closure with 51 each going to Brynlliw and Cynheidre and the rest redundant. Brynlliw/Morlais.

The colliery was closed in September 1985.

Some Statistics:

- 1905: Manpower: 18

- 1907: Manpower: 62

- 1908: Manpower: 102

- 1909: Manpower: 102.

- 1910: Manpower: 169

- 1911: Manpower: 192.

- 1912: Manpower: 319

- 1913: Manpower: 281.

- 1916: Manpower: 167.

- 1919: Manpower: 167.

- 1920: Manpower: 16716

- 1922: Manpower: 79

- 1923: Manpower: 182

- 1924: Manpower: 172.

- 1925: Manpower: 190.

- 1926: Manpower: 53.

- 1927: Manpower: 8.

- 1928: Manpower: 53.

- 1929: Manpower: 10.

- 1934: Manpower: 3

- 1947: Manpower: 3 on pumping operations.

- 1954: Manpower: 15 on development.

- 1961: Manpower: 341. Output: 63,100 tons.

- 1962: Manpower: 507. Output: 183,022 tons.

- 1964: Manpower: 691.

- 1965: Manpower: 743.

- 1969: Manpower: 877.

- 1970: Manpower: 820.

- 1971: Manpower: 700.

- 1972: Manpower: 713.

- 1974: Manpower: 907. Output: 314,000 tons.

- 1979: Manpower: 864. Output: 273,000 tons.

- 1980: Manpower: 819. Output: 273,341 tons.

- 1981: Manpower: 714.

The closure of the combine caused much bitterness locally, as can be shown by this extract from Hansard which records parliamentary debates:

Brynlliw Colliery – HC Deb 20 July 1983 vol 46 cc542-6542

Motion made, and Question proposed, That this House do now adjourn.— [Mr. Sainsbury.] 3.28 am

Mr. Gareth Wardell (Gower)

I welcome this opportunity to inform the House about a vital matter that affects my constituents. On 14 June this year, the National Coal Board’s south Wales area director announced to the NCB his recommendation that Brynlliw colliery be closed. Brynlliw is a colliery that I know well. I feel a strong empathy with the men who work there. It is my firm belief that the recommendation by Mr. Philip Weekes is premature as a decision and insensitive to the full implications of closure. First, let us consider the potential of the colliery. On 21 March 1983 a joint investigation team was established which included representatives of management, unions and employees. It made an in-depth study of the mine, and the report was submitted for discussion on 3 May 1983. The conclusions in the report did not point to a bleak future. Indeed, the opposite was true. Fifteen positive recommendations were made, including the urgent need to develop the S31 coalface. Some of those recommendations have now been implemented, but the key question remains: how much investment has the National Coal Board made, apart from normal development? For example, what capital has been injected into a new haulage system for the main laterals in the 6 ft seam? The NCB cannot sustain the view that Brynlliw’s coal reserves are exhausted. Nevertheless, it is important to point out that the total workable coal reserves at Brynlliw amount to at least 4 million tonnes— 1–9 million tonnes in the 3 ft seam and 2–1 million tonnes in the 6 ft seam. Tapping those reserves does not require a major expenditure programme. In the 3 ft seam, two short headings of 1 ft each would lead directly into the seam. In the 6 ft seam, only headings are needed, as there is no area of barren ground to work through. There is also a ready market for Brynlliw coal at the Aberthaw B power station. Indeed, that market has already been supplied successfully. For example, 191,500 tonnes of Brynlliw coal were burned at Aberthaw in 1979. In 1981, the figure was 126,000 tonnes. The existence of that market was confirmed on 12 April 1983, at a meeting at the headquarters of the Central Electricity Generating Board in London. Sir Walter Marshall, the CEGB chairman, gave me his assurance that every tonne of Brynlliw coal could be burned at Aberthaw.

Thus, in view of the investigation team’s report, the known availability of reserves, and the assured market, I conclude that prematurity of recommendation is a reasonable charge that can be levelled at the NCB’s south Wales area director. Secondly, my case rests on the insensitivity of the south Wales area director to the full implications of closure. The NCB states that 638 men will be found other jobs. However, if 638 jobs are available in other collieries in the area—which would be good news indeed—why have they not been advertised to date? The truth is that 638 jobs are not available in the surrounding pits. Men in other pits will be retired early, as will some of the men at present employed at Brynlliw. The closure of Brynlliw will mean hundreds of lost job opportunities in a county that has experienced the fastest rise in long-term unemployment of any county in Wales. Yet, on 22 January 1981, the Secretary of State for Wales, in a Welsh affairs debate, said: However, I believe that the NCB will find opportunity for additional investment to strengthen the position of many pits in Wales and to increase job opportunities within them.” —[Official Report, 22 January 1981; Vol. 997, c.448.]

Those words now seem to have a very hollow ring to them. There are other implications, but I shall confine myself to the contribution of deep mined relative to opencast-mined coal in Wales. If Brynlliw colliery closes, the question of where the replacement capacity is to be found must be posed.

The Royal Commission on energy and the environment argued powerfully that opencast operations should not exceed 15 million tonnes per annum.

The Government eventually — I emphasise “eventually”—responded on 22 May this year to the Royal Commission’s report of July 1981. Page 25, paragraph 74, of the Government’s response shows a difference in attitude between the Royal Commission and the Government, because the Government do not accept that the ceiling of 15 million tonnes should in any way be sacrosant. I believe that opencast coal sites remain classic examples of the misallocation of resources whereby the people living near to them are not compensated fully for the ravaging of their environment and the intrusion into their lives of noise, dust and vibration. Often a whole generation has to endure the unintentional, negative side effects of such developments.

In the constituency of my hon. Friend the Member for Carmarthen (Dr. Thomas), the Department of Energy, in its folly, has said that the excavation area to be authorised at Glyn Teg should not approach a line nearer than 82 yards from the nearest occupied dwelling. What a concession!

If the Government give a free hand to the National Coal Board to substitute opencast for deep-mined coal without paying full compensation for loss of amenities to people living near those sites, they are engaged in a socially reprehensible policy.

I have sought to show that the closure of Brynlliw colliery is unnecessary, and that, if catried through, it will inflict another serious blow to the prospect of more job opportunities in Wales, while imposing more opencast operations on the lives of many more people.

On 17 February 1981, the then Secretary of State for Energy said: The Government will view with sympathy the social problems brought about by redundancies.”—[Official Report,17 February 1981; Vol. 999, c. 142.]

The people of Gower and Wales know only too well that sympathy will not protect their living standards. I hope that the Minister will offer the miners of Brynlliw more than sentiment this evening. 3.38 am

The Under-Secretary of State for Energy (Mr. Giles Shaw)

I congratulate the hon. Member for Gower (Mr. Wardell) on raising this issue, which is of such importance to his constituents. We are well aware of his assiduity in looking after constituency matters and raising them in the House. I feel certain that what he has said tonight will form an important part of the discussions about Brynlliw colliery.

As the hon. Gentleman knows, the decision, if it is confirmed after appeal—and the appeal is pending—on the colliery’s future is taken in the context of what the National Coal Board views as the problems in o the area involved. It is an individual and a special matter, but the context in which the decisions are set is important. I remind the House that just over a week ago I brought before the House the draft Coal Industry (Borrowing Powers) Order 1983. It set out the facts fairly starkly on the National Coal Board’s current financial position. I make no apologies for referring to that matter again, because despite the increasing levels of productivity and the huge investment of the past 10 years, the industry’s finances continue to deteriorate.

In 1979–80 the board’s loss before payment of deficit grant was £159 million. In 1980–81 the figure was £207 million, in 1981–82, £428 million, and in 1982–83 the figure had risen to about £485 million. The signs are that the 1983–84 loss before deficit grant could be not far short of £600 million.

Those are the bare facts of the industry’s global problem. I accept that it is not the precise problem of the location to which we are referring, but that is the global argument.

The cause of those increasing losses is than the board is producing more coal than it can sell, a portion at very heavy losses. As the board itself has said, 10 million tonnes of its deep-mined capacity gives rise to a net loss on revenue account of about £400 million a year, both in direct operating losses and in further losses that arise in disposing of or stocking the surplus production.

That £400 million loss is not the fault of the managers and men involved. It arises largely from the geological conditions at the pits concerned. With more and more fine new capacity coming on stream, it no longer makes sense for men to scratch around at those pits, often in very poor working environments. As the report of the Select Committee on Energy pointed out last December, as the Monopolies and Mergers Commission stated in its report, and as the Government’s published objectives for the chairman of the board state, action to bring production into line with that demand which can be met profitably is now imperative. In this context I think that it will help then House if I describe in detail the actions which I understand the board has taken over Brynlliw colliery, which lies in the constituency of the hon. Gentleman, is 78 years old, and currently employs about 640 men. My purpose is to show that the board has taken every opportunity to keep Brynlliw going in the hope that the situation would improve. If, following the forthcoming appeal, the board concludes that there is really no hope left, that will not be 21in any way an arbitrary or lightly considered decision. It will follow from discussions that have spread over many years, as the hon. Gentleman made clear. The losses at Brynlliw are accelerating. In 1978–79 it was part of the Brynlliw—Morlais combined mine, which lost just under £10 per tonne of coal produced. The losses of the combined mine rose to nearly £16 per tonne in 1979–80, and over £27 per tonne in 1980–81. In May 1982 the Morlais section was closed, by local agreement with the unions, and in 1981–82 the losses fell to just under £20 per tonne. But even that modest improvement did not, unfortunately, last. In 1982–83 Brynlliw produced 122,000 tonnes of coal, only just over half the previous years’ total. Output per manshift was 0.92 tonnes, well down on the previous year and not much over one third of 545the national average of 2.44 tonnes. The financial loss was £6.8 million, nearly £56 per tonne of coal produced and over £10,000 for every man on the colliery books. The cumulative loss in the period 1979–80 to 1982–83 was no less than £22 million—money which could have been used more effectively in developing new capacity. Were operations to continue through 1983–84, the NCB would expect a further loss of at least £7 million.

The hon. Gentleman raised two questions about investment. The first was transportation on the new haulage systems in the 6ft seam. That is an extremely technical matter, but I am assured by the board that it has considered it carefully and discussed it with the unions. It was fully taken into account by the area director when he made his decision on the pit. It was not ignored in the board’s assessment. These losses, too, contribute to a deteriorating position within the board’s south Wales area as a whole. The operating loss in south Wales was £69 million in 1980–81 and £96 million in 1981–82—some 40 per cent. of the board’s total operating loss on deep-mined coal. I understand that the 1982–83 accounts of the board, to be published next week, will show the south Wales loss higher still, and a similar proportion of the national loss. Despite that position, the NCB has maintained new investment in south Wales at about £30 million per year. Earlier this year it sanctioned investment of £12 million in further development work at the profitable Betws anthracite mine only about 10 miles from Brynlliw. This will lead to more jobs, some of which could be filled by men from the Brynlliw colliery. The hon. Gentleman asked about the CEGB’s acceptance of coal from Brynlliw. While the CEGB claims that it could accept Brynlliw coal if prepared to the required quality specification, there is the recognised need to safeguard other Welsh collieries which could also meet CEGB specifications, at much lower costs. As the hon. Gentleman knows, Brynlliw is not the only CEGB source of coal for Aberforth. It could be produced from other Welsh mines at much less cost. The board must consider factors such as that in making its decisions. As the hon. Gentleman has so fairly set out, in view of that position it is not surprising that the history of the Brynlliw mine has led to a series of special meetings under the colliery review procedure. Under this procedure, introduced in 1973 by agreement between the board and the unions, each of the board’s 12 area directors reviews the performance of every colliery in his area at regular intervals. There was a reconvened meeting on Brynlliw/Morlais in May 1979 and in January 1981 at a general review meeting the position was noted as being extremely serious. On 13 February 1981 the area director told the unions that he proposed to close the combined pit, along with four others, as soon as possible.

Following the tripartite meeting in February 1981, at which my right hon. Friend the Member for Guildford (Mr. Howell), who was then Secretary of State for Energy, agreed to review the finances of the board, the proposal was withdrawn and discussions continued under the review procedure. As a result of those discussions, the Morlais section closed in May 1981. By December 1982 the operating results being obtained prompted the area director to ask for a further reconvened review meeting, which was held on 21 March 1983. This meeting decided to set up the joint investigation to which the hon. Gentleman referred and the results of that investigation were discussed at a review meeting on 3 May. At the end of that meeting the area director said that Brynlliw was one of the most serious problems facing the south Wales coalfield, although everyone involved had made every effort to improve results. He said that the area management would now make its own evaluation of the position and report back to a further reconvened meeting. That further meeting was held on 14 June.

The area director said that he had no alternative but to recommend closure. However, every man at Brynlliw who wished to transfer to another colliery would be offered a job. For those who did not wish to remain in the industry the terms financed by the Government under the redundant mineworkers payments scheme would be available. No one would become unemployed against his will. As the hon. Gentleman knows, the National Union of Mineworkers has appealed to the board at national level against that decision and I understand that the appeal will be heard on 16 August. If following the appeal, the board confirms that the colliery must close, I think that the account that I have given shows that this will not be an arbitrary or capricious decision. I would emphasise, though, that the decision is the board’s and not the Government’s.

I draw the hon. Gentleman’s attention to the presence of my hon. Friend the Minister of State, Welsh Office, on the Government Bench, despite the lateness of the hour, to show his Department’s concern about this important matter. It is, of course, for the board to manage the industry. In present circumstances, that must mean taking action to deal with loss-making pits that can never return to viability. The Board has said, however, that it aims to deal with the problem in a humane manner, with proper respect for men who have perhaps spent a lifetime in the industry. As Sir Norman Siddall said last week, cooperation and not confrontation is the way to proceed.

The hon. Gentleman said that he hoped I would offer more than sympathy. I must inform him that my contribution to the debate has sought to set out the facts against which a difficult decision has to be taken. Decisions will inevitably involve, I trust, sympathetic judgment, because that is the correct way for management to proceed, but I think that even the hon. Gentleman will recognise that sometimes decisions are inevitable in view of the facts that the board has to face.

That is a matter for the board, but I assure the hon. Gentleman that I personally will send to Norman Siddall, the chairman of the board, the official Report of today’s debate to emphasise the fact that the hon. Member for Gower has raised in detail the problem of Brynlliw and that I in my turn, as the Minister responsible at the Department of Energy, have put before the House the important considerations that ought to be taken into account before the decision is finally made. Question put and agreed to.

Adjourned accordingly at ten minutes to Four o’clock am.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page