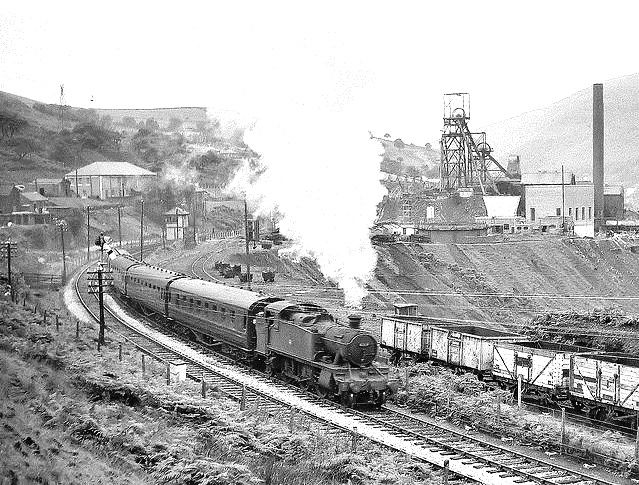

Croeserw (SS 8420 9575)

Croeserw (SS 8420 9575)

The sinking of the two shafts to this colliery started in June 1903. The No.1 shaft was sunk to the Gorllwyn seam to a depth of 525 yards (480m) and later deepened to just below the Six-Feet seam to a depth of 708 yards (647m) in 1921, and was the downcast ventilating shaft. The No.2 shaft was sunk to Lower-Nine-Feet seam and was used as the upcast ventilating shaft. The shafts were 45 yards apart and 20 feet in diameter. A cross measures drift was then driven down to prove the other coal seams. There were landings at the No.2 Rhondda Level and with No.2 Pit at a depth of 516 yards. There was a lodge room for water pumping purposes at 360 yards.

There were also two slants, or inclined levels, driven into the No.2 Rhondda sea of the Upper Coal Series.

The No.2 Pit was deepened by the contractors Cementation between September 1960 and February 1962 with the pit bottom constructed at a depth of 1,504 yards (1,375m).

The Bute seam was worked as the New seam at a thickness of 36 inches. The Lower Nine Feet seam was called the Seven Feet seam and had limited workings at a thickness of 48 inches. Attempts were made to work the Upper Nine Feet seam which had a thickness of between 30 inches to 48 inches. The Six Feet seam was worked and had a thickness of 77 inches of coal with dirt bands. The Four Feet seam also had dirt partings and was worked on a small scale at a thickness of 48 inches. Also worked on a small scale was the Lower Pentre seam which was called the Two and a Half in this area. It had a section of 29 inches.

This colliery’s coals were generally classed as type 201B Dry Steam Coals, usually non-caking and low volatile. They had a low ash content of around 5% to 9% and low sulphur content of between 0.6% and 1.5%. Their main uses were for steam raising in boilers of ships, locomotives, power stations etc.

The Duffryn Rhondda Colliery Company was registered on the 12th of January 1903 to take over the property and business of the Duffryn Rhondda Company. In 1913 it was still owned by the Duffryn Rhondda Colliery Company Limited, whose sales agents were Thomas and Davey of Cambrian Buildings, Cardiff. There then followed a confusing series of takeovers and amalgamations.

Along came the Imperial Navigation Coal Co. The Chairman and Managing Director were Sir D. R. Llewellyn, Bart., and the Directors were Lord Buckland, Mr. C. P. Hailey, Mr. W. P. Miles, Mr. J. B. Rees and Sir W. Carruthers. The capital was £155,000 Ordinary Shares. It acquired Duffryn Rhondda Colliery Co, Cynon Colliery Co, and subsequently was itself absorbed by North’s Navigation Collieries (1889) Limited.

On the 12th of January 1903, the Duffryn Rhondda Colliery Company took over from the Duffryn Rhondda Company as owners of the colliery. In the May of 1910, it was reported that the profits for 1909 were £7,992. 6/-, added to this was the previous year’s profit which made a total available to the company of £15,168, with the disposable balance being £10,047. The directors agreed to pay a dividend of 5% amounting to £5,842 and for the rest to go onto the following year’s accounts.

In April 1907 the local paper reported;

Duffryn Rhondda Colliery Company of Port Talbot have been carrying out developments on a most extensive scale, and at no distant date, it is hoped that this colliery will be one of the largest in West Wales. Situated in the Duffryn Valley, the colliery is well tapped by the Rhondda and Swansea Bay Railway, and the railway company, in anticipation of these developments, have constructed special sidings to this pit. The company, of which Colonel Wright is the chairman, have the services of some of the most capable gentlemen in South Wales, and especially so in Mr. Fred E. Jacob, M.E. Owmitvon. The Jacobs have been long associated with the Duffryn Colliery, and another brother, Mr. Percy Jacob, is managing director of Cynon Colliery, which is near to Duffryn. Mr. Fred E. Jacob told one of our representatives on Thursday that the operations at the colliery had been very successful, and a new pit had been sunk. The coal was of splendid quality. They had gone down to a depth of 530 yards. This was as far as they would go at present. Of course, the extensions had meant employment for a large number of men. They had some of the most modern plant, and everything was up-to-date. They were at present turning out 400 to 500 tons per week. By September 1907 the pit was producing between 400 and 500 tons of coal a day from the Two-Feet seam and was ready for full production. To allow this the Union and Management came to an agreement over a price list for cutting coal.

It was on the 6th of June 1910 that Edwin Hill, a collier, aged 36 years died under a fall of roof at the working face. While he was holing the roof gave way at a joint at the face and fell on top of him.

1912 was a particularly bad year for the men at this pit:

- April 12th, Richard Rees aged 32 years and an assistant rider died under a roof fall.

- September 2nd, John Edwards, a crane driver who was found dead on his crane.

- October 22nd, Albert Pullen, aged 27 years and a haulier, died when the bolts holding the pedestal caps of the haulage engine broke, allowing the drum to run free, and the journey wild. The trams ran into a group of hauliers at the bottom of the incline, killing the deceased and injuring another.

In 1908/9 the levels were managed by Arthur Richards and the Pits by W.H. Plummer. In 1913 by A.J. Price, and in 1918 the Levels by G. Lloyd and the Pits by E. J. Green. In 1913 it was still owned by the Duffryn Rhondda Colliery Company Limited, whose sales agents were Thomas and Davey of Cambrian Buildings, Cardiff. At that time the Slant employed 426 men, and the Nos. 1 & 2 Pits employed 692 men. However this company didn’t last very much longer and in February 1914 it was put up for auction at Cardiff but only received three bids; £40,000, £50,000 and £51,000 and was withdrawn. On the 25th of January 1914 the following report appeared in the newspapers:

On the 6th of March 1914, the Colliery Guardian reported that the receivers had laid off 1,000 men at this colliery. Work restarted on the 27th of March 1914. In March 1914, high-level talks between the South Wales Miners Federation’s William Jenkins, miner’s agent, and Daniel Rees the new agent for the new company, agreed to re-open the No.2 with repairers the following week with the aim to employ 300 men as soon as possible.

On top of this, it was reported that the new sinking would start at once.

This is a very good description of this type of work that was used at Duffryn Rhondda;

There are 110 working places, and as there is a distance of twelve yards between each of these, walking around the face is similar to walking by the side of a wall of coal 7 feet thick for an uninterrupted distance of three-quarters of a mile, meeting two men busy at work in each roadway. The coal worked by these men is first taken by horse haulage a short distance, to a point on the main road, technically called the ‘double parting’ which is over two and a half miles from the pit bottom. At this point, it is taken by main and tail rope haulage in journeys of 25 to 30 trams a distance of about half a mile, when it is attached in like manner to an endless rope haulage which conveys it nearly two miles to pit bottom. The regularity with which the full journeys arrive at pit bottom every twenty minutes indicates a high level of efficiency. This haulage level is laid with three lines of rail throughout its distance, having double roads at meeting places, and is absolutely straight.

By 1917 the colliery was in the hands of the Imperial Navigation Coal Company Limited who were members of the Monmouthshire and South Wales Coal Owners Association. It remained in their hands until 1929 when the Duffryn Rhondda (1929) Limited was formed under the chairmanship of Sir D.R. Llewellyn. This Company was based at Commercial Buildings, Port Talbot and used Gueret, Llewellyn and Merrett Limited as their sales agents. The other directors were; W.M. Llewellyn, H.H. Merrett, Sir John F Beale, J.H. Jolly and T.J. Callaghan. On the 29th of January 1930, the company was merged into Llewellyn’s Welsh Associated Collieries, which merged with Powell Duffryn in 1935 to form the Powell Duffryn Associated Collieries Limited. It remained with Powell Duffryn until Nationalisation in 1947.

In 1920 the pits were working the Seven-Feet seam at a depth of 800 yards and the New Seam at a depth of 811 yards. Both seams were inclined at around 20 degrees and rising towards the south. The No.1 Pit could raise two trams per wind in 60 seconds while winding in the No.2 Pit was from the Gorllwyn landing at a depth of 500 yards. It was equipped with single deck cages carrying two trams per wind in 50 seconds.

The No.2 Rhondda House Coal Slant used two electrically driven haulages to bring out the coal a distance of two miles. Ventilation was by a Walker type fan, 21 feet in diameter, capable of producing up to 300,000 cubic feet.

In 1930 it was managed by V.P. Leyshon and employed 388 men working underground in the Six-Feet seam and 79 men working at the surface of the mine. In 1935 the Nos. 1 & 2 Pits employed 165 men on the surface and 1,250 men underground, with the Slant employing only 5 men underground. The seams worked at that time were the Six-Feet, Seven-Feet, New and Four-Feet steam coal seams. The colliery had its own coal preparation plant (washery). The manager at that time was W. Bassett. In 1938 pithead baths were constructed at this colliery, they had the capacity to accommodate 1,496 men. In 1943/5 the manager of the Pits was L.N. John and they employed 669 men working underground in the Four-Feet, Six-Feet, Nine-Feet and Seven-Feet seams and 178 men working at the surface of the mine. The Levels only employed one man on pumping.

On Nationalisation in 1947 Duffryn Rhondda Colliery was placed in the National Coal Board’s South Western Division’s No.2 (Maesteg) Area, Afan Group, and at that time the pits employed 170 men on the surface and 834 men underground working the Six-Feet and Two-Feet-Six seams. The slant had been closed with only one man employed there on pumping operations. The manager at that time was L.N. Jones. In 1954 the manager was G.H. Thomas, and in 1955 out of the total colliery manpower of 1,080 men, 501 of them worked at the coalfaces. The coalface figure rose to 534 men in 1956 and remained at this figure in 1958.

In 1956 the pit was working the Six-Feet seam which was 72 to 90 inches thick and machine cut. Each collier had a stent of six linear yards on a 48-hour turnover which yielded 22 tons of coal. The coal at the coalface was undercut by five feet and then got by compressed air picks and loaded by hand shovels onto a scraper chain conveyor.

The jib of an undercutter, at Duffryn Rhondda, would cut under the coal for five feet on the backshifts. The face would then ‘spragged’ wooden props wedged against it to prevent it from falling over until the colliers arrived and loaded it onto the conveyor. Next, a collier using a ‘blast’ compressed air pick.

In 1959 along with Glyncorrwg and Avon collieries the methane in the coal seam was extracted and piped to the Aberavon works of Port Talbot Gas and used to feed 45,000 homes.

In 1961 it was still in the No.2 Area’s, Afan Group along with Avon, Garth Tonmawr, and Glyncorrwg collieries. The total manpower for the Group was 2,468 men, while coal production for that year was 601,783 tons. The Group Manager was V.H. Evans and the Area Manager was W.B. Cleaver.

In June 1963 the winding engine for the downcast shaft was electrified at a cost of £133,000. The new engine was the same horsepower as the upcast shaft, 2,400, and could raise 180 tons of coal every hour from a depth of 2,700 feet.

In July 1966 the NCB informed the National Union of Mineworkers that attempts to install power loading coalface equipment at this colliery had failed due to the difficult conditions despite the efforts of management and men and this pit was then losing £4 on every ton of coal it produced. The NUM argued that it was one of the most modern collieries in the Coalfield and that it had almost unlimited reserves. Those arguments fell on deaf ears. The colliery continued to work the same seams with roughly the same manning until closure in November 1966.

Many years later Tower Colliery worked the coal reserves left behind by the closure of Duffryn Rhondda Colliery.

Some Statistics:

- 1899: Manpower: 143

- 1900: Manpower: 216

- 1901: Manpower: 233

- 1902: Manpower: 320

- 1903: Manpower: 309

- 1905: Manpower: 682

- 1907: Manpower: Pits: 360 levels: 366

- 1908: Manpower: Pits: 280. Levels: 429.

- 1909: Manpower: Pits: 429, Slant: 280.

- 1910: Manpower: 954.

- 1911: Manpower: Pits: 393, Slant: 355.

- 1912: Manpower: 1,042

- 1913/5: Manpower: Pits: 692. Levels: 426.

- 1916: Manpower: Pits: 692. Levels: 200.

- 1918: Manpower: Pits: 1,191. Levels: 190.

- 1920: Manpower: 200

- 1922: Manpower: 300

- 1923: Manpower: No.1 Pit: 750. No.2 Pit: 550, No.2 Slant: 290. Output: 360,000 tons

- 1924/5: Manpower: 300

- 1928: Manpower: 462

- 1930: Manpower: 467.

- 1931: Manpower: 1,125.

- 1932: Manpower: 1,270.

- 1933: Manpower: 1,370.

- 1934: Manpower: 1,420. Output: 360,000 tons.

- 1940: Manpower: 968.

- 1941: Manpower: 9.55

- 1942: Manpower: 645.

- 1944: Manpower: 782.

- 1945: Manpower: 839.

- 1947: Manpower: 1,004.

- 1948: Manpower: 1,015. Output: 260,000 tons.

- 1949: Manpower: 1,075. Output: 260,000 tons.

- 1950: Manpower: 1,031.

- 1953: Manpower: 1,093. Output: 272,000 tons.

- 1954: Manpower: 1,032. Output: 256,066 tons.

- 1955: Manpower: 1,080. Output: 254,010 tons.

- 1956: Manpower: 1,106. Output: 230,039 tons.

- 1957: Manpower: 1,139. Output: 243,666 tons.

- 1958: Manpower: 1,143. Output: 229,428 tons.

- 1960: Manpower: 1,059. Output: 216,035 tons.

- 1961: Manpower: 989. Output: 165,337 tons.

- 1964: Manpower: 1,012.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page