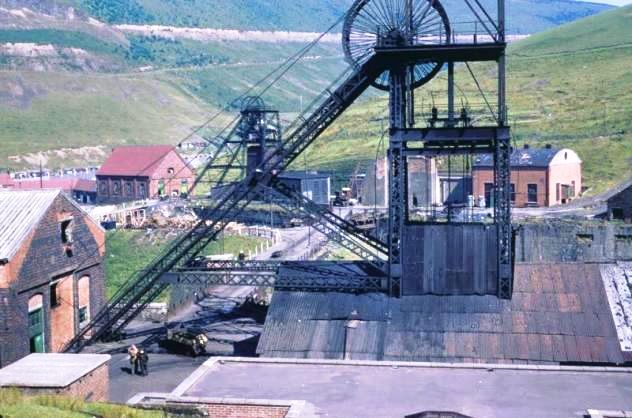

Avon Colliery

Abergwynfi, Afan Valley (SS 8948 9617)

This pit was sunk between 1877 and 1882 by Sir Daniel Gooch to work the Six-Feet seam, with the manager in 1878/84 being J.G. Morris, and in 1896 it was J.G. Morris.

The level worked in conjunction with the pits was abandoned in 1905. The decision to sink this pit came about upon the completion of the Bridgend to Blaengwynfi branch of the Great Western Railway, the chairman of the GWR, Sir Daniel Gooch decided to supply its locomotives with coal from their own mine.

The South Pit was sunk to a depth of 1,504 feet 4 inches, and the North Pit to a depth of 1,528 feet 2 inches, these pits were 75 feet apart and either side of the Glyncorrwg geological fault which had a throw upwards/downwards of 140 feet.

The HMI Report for 1881 included;

About five or six miles from Maesteg the Great Western Railway Company are sinking two shafts known as the Avon Colliery to win the steam coals. On the 6th of September eight men were employed in walling one of the shafts at a point sixteen or eighteen yards from the bottom, which distance was filled with water. The stage upon which they were working was suspended by two wire ropes, one of which broke causing the stage to tilt and precipitating seven of the men into the water below; three of them were rescued and four drowned. From my examination on the following day I was of opinion that sufficient care had not been exercised by the mechanical engineer in examining the rope that broke.

At the inquest, the jury returned a verdict of accidental death.

The local newspaper reported

A fatal accident occurred in the Avon Colliery, Abergwynfi, near Maesteg, on Monday afternoon about half-past-three. The colliery is situated between the Llynfi and Rhondda Valleys, the particular place being better known by the Cape. The colliery is the property of the Great Western Railway Company, and the first sod was only cut about two years ago by Sir Daniel Gooch. On Monday seven masons were engaged in the pit when the guide rope of the north shaft stage broke, and four men were precipitated into the water below and drowned. Three others were injured. Of the four that were drowned, two are Joseph Pulman and Thomas Lewis, of Mountain Ash. Dr. Davies and his assistant attended the injured men. The bodies of the four men drowned by this dreadful accident at Avon Colliery on Monday were recovered by about nine o’clock in the evening.

The persons drowned are:

- Joseph Pulman, mason, single, from Mountain Ash.

- Joseph Harris, sinker, married, Neath.

- William Shepherd, sinker, Neath.

- Thomas Lewis, single, mason, Mountain Ash.

The inquest was opened on Tuesday by Mr. Howell Cuthbertson, Neath, at the Gelli Hotel, Abergwynfi. Evidence was taken in recognition of the bodies, and an order was given for the burial of the same:

The Great Western Railway Company will defray all the expenses of the funerals. After taking formal evidence, the inquest was adjourned until Tuesday next. The four injured are recovering well, the fright being rather more than the injuries sustained. It is somewhat remarkable that it was not the proper turn of any of the men to work, with one exception. It is said that they exchanged turns with another gang, the escape of John Davies of Neath, is quite miraculous. He fell from the stage into about seven yards of water but managed to raise himself to the surface and grappled a rope suspended near him. In a few moments, he was raised in the cage to the pit top. This is the only accident to have occurred in the colliery since its commencement.

To provide coal for the sinking engines at this pit a level was driven into the hillside near the upcast winding engine house. The winding engine for the upcast ventilation shaft was originally the locomotive engine called ‘Alexander’. It remained in service until 1907. Ventilation was originally by a steam-driven 14.5 feet diameter Schiele type fan.

By 1896 geological difficulties had prevented the pit from reaching its targets and the owners asked for a reduction in the rates “on account of the colliery not being in full work” this was declined.

The pit was closed on the 12th of August 1903 until re-opened in March 1904 when they started looking for new coal seams to work, by April they had struck “a good seam four feet three inches thick” and it was all go again. The owners decided to improve the surface plant, replacing the boiler plant and building a chimney stack 175 feet high, they also introduced haulage engines underground to cut the number of horses used.

In 1906 ownership changed to a subsidiary called the Great Western Colliery Company who placed the pit on a temporary maintenance basis.

Trouble erupted in the pit and village in November 1907 when the 600 colliers went out on strike over the price list for a new coal seam to be worked. The South Wales Miners Federation big boys were sent in to effect a settlement with emotions running so high that extra police were drafted into Abergwynfi. When information reached the village that some men intended to return to work the following Monday, the women agreed to hold a ‘white shirt’ parade to prevent them. Wisely no men turned up for work. This colliery was then officially closed in 1908, it remained idle for two years until in October 1910 rumours circulated that a group of ‘gentlemen ‘ from Cardiff Docks with extensive colliery concerns were interested in buying it, and running it as a separate concern. Whether this was the Ocean & Wilson’s Company I am not sure but the Ocean Coal Company purchased it in 1912, but it wasn’t until March 1915 that a Mr, Jones, who used to be a manager at Cwmdare was appointed manager at Avon with the colliery now in production. This company was a member of the Monmouthshire and South Wales Coal Owners Association.

The pit worked fairly regularly during the 1914 -1918 war, but from 1922 onward it was either closed or working slack time (on a rota system which often meant months between turns).

In 1918 this colliery was still managed by J. Jones (he was still the manager in 1923) and employed 322 men underground and 104 men on the surface, but from 1922 it hit bad times and was either closed or working sporadically. It closed altogether from 1924 to 1928 but the workmen and their union remained active.

After the general strike of 1926, Avon Colliery was reopened in March 1929 and by April was producing 2,600 tons of coal weekly. In 1930 Avon Colliery was managed by R. Hughes and employed 357 men working underground and 64 men working at the surface. It was managed by T. Thomas and employed 210 men underground and 50 men on the surface in 1934. It closed yet again in 1936, for three months.

When France fell to the Germans in 1940 the main market for Avon’s coal was cut off and the pit closed until re-opened in 1946. In 1943/5 the pit was managed by G. Williams and there were only 71 men working underground and 42 men at the surface. The pit was re-opened in 1946 and manpower rose to 351 men underground and 91 men on the surface in 1947, and again rose to a post nationalisation peak of 539 men underground and 130 men on the surface in 1954.

The colliery came under the control of the National Coal Board following Nationalisation in 1947 who placed it in the No.2 Area of the South Western Division and at that time it was working the Six-Feet and Two-Feet-Nine seams.

In 1953/54 extensive modernisation was carried out at this pit with the surface re-constructed, with a new tram circuit, pithead baths and medical centre (the baths and medical centre cost £67,000). In 1954 the winding engine for the downcast shaft was electrified and was then capable of raising 140 tons of coal every hour. The single-deck carriages that carried two trams were replaced by a double-deck system that could carry 30 cwts of coal on each deck, an improvement of 50%. It was the first winder in the United Kingdom to use dynamic braking.

The seams being worked at that time were the 54-inch thick Two-Feet-Nine seam and the 50-inch thick Six-Feet seam, both seams were machine cut and worked by the longwall system. The NCB in January 1956 gave it an estimated life of 40 years.

In 1955 out of a total of 662 men working at this colliery, 348 of them worked at the coalfaces. The manager at that time and in 1949 was A.G. Williams. In 1954/55 this colliery was one of 42 that caused concern to both the NUM and the NCB over the high levels of accidents.

In February 1955 the old steam winders were converted to 1,100 hp electric ones, they could haul 3 tonnes of coal or 5.5 tonnes of dirt, 1,575 feet in 76.3 seconds. It was the first winding engine in the United Kingdom to use dynamic braking.

In 1954 the “Coal News” had this to say about Avon Colliery:

Once known as the umbrella pit due to its intermittent working, Avon Colliery in South Wales has been producing its household and dry steam coals steadily since 1946 and throughout modernization and electrification. For nearly 40 years the people of Blaengwynfi village knew little real security. Their home pit –Avon Colliery –suffered long periods of idleness or intermittent working, opening and closing so often that it became known as the ‘Umbrella Pit’. Its last long period of idleness began on the day when France capitulated and that market was lost in Wales. Avon no longer deserves its old nickname. Re-opened in 1946, it has worked steadily ever since. Its dry-steam coals are in demand for modern grates. Newer mining techniques are helping to overcome difficult natural conditions. The pit-top has been modernized, the pit electrified. These changes, and the new housing estate at Cymmer to which many of the people of Blaengwynfi have moved, prove that the period of stagnation has ended.

Surface modernization started in 1953 when the single deck carriages at the coal drawing shaft, holding two small trams, were replaced by double-deckers carrying one large (30 cwt) tram per deck. This increased the shaft’s capacity by 50%. A modern tram circuit was installed, the new pithead baths were opened, a boom to many men without baths in their homes. With the baths came a medical centre and a full-time nursing sister to Avon Colliery. In the next year, there was a new electric winding engine in the coal winding (downcast) pit. Months before the changeover (planned for the annual holidays) an annexe was built on the existing winding engine house to take the new motor, low tension switchboard, rectifier and contactor. The roof of the engine house was removed, the side walls built higher, girders with runner blocks installed for dismantling the old engine and erecting the new, and a new roof put on. The foundation for the motor was so constructed that it would finally be joined to the foundation of the new winder when that had been constructed. In holiday week, despite many difficulties, the changeover was made to time and the was re-opened for the first shift after the holidays. The new winder can make about 47 winds (some 140 tons) an hour. It is the first AC winder in this country to use the new GEC system of dynamic braking and speed control. Steam-driven fans, compressors and underground haulages have been replaced by electrically driven equipment. A submersible pump is to be put in the upcast shaft.

In 1959 compulsory retirement at 65 was introduced with this pit having 16 men over that age. In that year it was working the 60 inches thick Six-Feet seam from which the methane gas was extracted and along with the gas from Glyncorrwg and Duffryn Rhondda collieries piped to the Aberavon gas works and used to service 45,000 homes.

It was in the early hours of Wednesday the 13th of October 1957 when men working down the pit heard a loud bang. It had been caused by an explosion near pit bottom, when they investigated they found a man badly burned, he was sent to hospital where it was reported that he was in a critical condition. George Davies was nearby, he says:

There was just one deafening bang, I was in the cloud of dust and pulled my cap down over my face. It was a frightening experience but I suppose that I can count myself as a lucky man. In another five minutes, I would probably been in the same place as where the explosion occurred.

The National Union of Mineworkers Lodge at Avon Colliery failed to rally enough support from their colleagues at the other pits in south Wales to strike over its closure which was carried out on September 26th 1969 due to the poor quality of its coal. It was working the Four-Feet seam on closure.

Just a few of the early fatalities at this mine:

- 19/08/1887, John James, Age: 55: Repairer: Fall of the roof at the entrance to the stall

- 1/09/1887, John Morgan, Age: 14, Collier: Fall of clod.

- 25/03/1890, Thomas Davies, Age: 52: Collier: Fall of roof, clift,

- 9/05/1892, Edward Hughes, Age: 21: Haulier: In jumping off shafts he fell and was run over by trams.

- 29/07/1892, Isaac Jenkins, Age: 45: Collier: Fall of the roof at face 10/11/1892, David Simeon, Age: 21: Shoeing smith: Fall of the roof at the face which was fairly well timbered.

- 30/04/1894, David S. Phillips, Age: 13: Door boy: Crushed between a tram and pair of timbers.

- 14/12/1894, William Bowen, Age: 4: Coal tipper: Crushed by a waggon

- 24/12/1929, Joseph Lewis, Age: 54: Day labourer: run over by trams.

Some Statistics:

- 1896: Manpower: 559.

- 1899: Manpower: 600.

- 1900: Manpower: 653.

- 1901: Manpower: 694.

- 1902: Manpower: 746: Level: 74.

- 1903: Manpower: South Pit: 224, Level: 88.

- 1905: Manpower: 386. Level: 75.

- 1907: Manpower: 621.

- 1909: Manpower: 907.

- 1910: Manpower 30.

- 1911: Manpower: 31.

- 1912: Manpower: 25

- 1918: Manpower: 426.

- 1919: Manpower: 445.

- 1920: Manpower: 445.

- 1922: Manpower: 445.

- 1923: Manpower: 599.

- 1924: Manpower: 674.

- 1925: Manpower: 672

- 1926: Manpower: ??

- 1927: Manpower: 53.

- 1928: Manpower: 44.

- 1929: Manpower: 45.

- 1930: Manpower: 421.

- 1931/2: Manpower: 480.

- 1933: Manpower: 276.

- 1934: Manpower: 260.

- 1937: Manpower: 415.

- 1938: Manpower: 229.

- 1940: Manpower: 440.

- 1941/2: Manpower: 520.

- 1944: Manpower: 70.

- 1945: Manpower: 113.

- 1947: Manpower: 442.

- 1948: Manpower: 452. Output: 90,000 tons.

- 1949: Manpower: 671. Output: 90,000 tons.

- 1950: Manpower: 669.

- 1953: Manpower: 694. Output: 196,000 tons.

- 1954: Manpower: 669. Output: 172,845 tons.

- 1955: Manpower: 662. Output: 157,677 tons

- 1956: Manpower: 638. Output: 150,466 tons.

- 1957: Manpower: 634. Output: 151,686 tons.

- 1958: Manpower: 634. Output: 141,691 tons.

- 1960: Manpower: 533. Output: 116,722 tons.

- 1964: Manpower: 527.

- 1969: Manpower: 448.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page