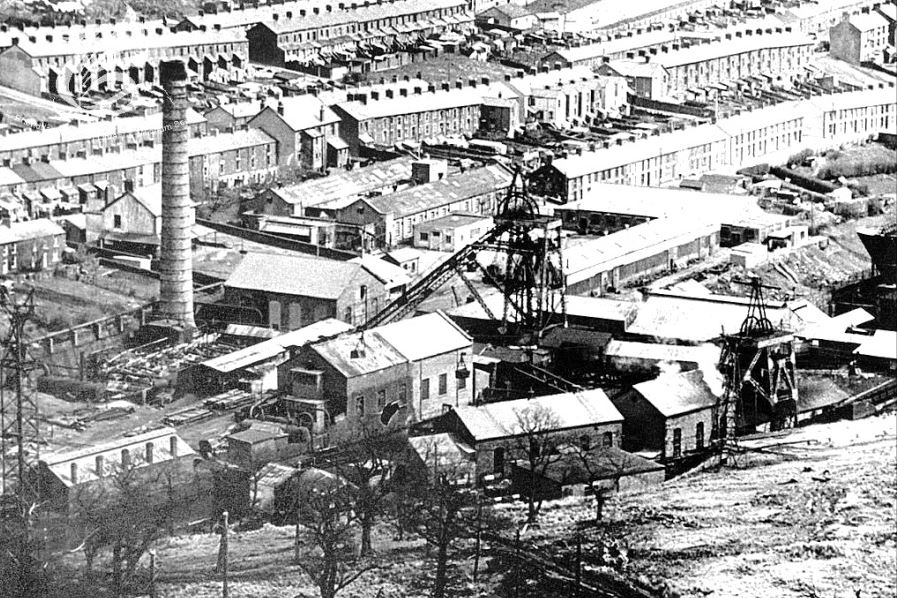

Near Treorchy, Rhondda Fawr Valley (951958)

Near Treorchy, Rhondda Fawr Valley (951958)

Between 1864 and 1866 a partnership consisting of David Davies, Edward Davies Thomas Webb, Morgan Joseph, John Osborne Riches, Abraham Howell and E Roberts negotiated the leases for the mineral rights of 8,000 acres beneath Cwm Parc and Maendy and commenced to sink the Maindy and Park Pits. In 1867 they formed the private limited company of David Davies and Co., which had a capital of £240,000 divided into shares of £100 each.

Their next venture was at the Dare Colliery where sinking was completed in April 1870 to a depth of219 yards. The Two-Feet-Nine seam was found at a depth of 82 yards, the Four-Feet at a depth of 102 yards, the Six-Feet at 132 yards, the Red Vein at 137 yards, the Nine-Feet at 167 yards and Brunts’ seam at a depth of 192 yards. The Three-Feet-Ten seam was 221 yards deep, and Phils’ seam 231 yards deep. This colliery was bounded by Park Colliery to the east, Pentre Colliery to the west, Maindy Colliery to the south and Tylecoch Colliery to the north.

Phils seam was really the Middle section of the Seven-Feet seam and was worked at a thickness of 48 inches. The Three-Feet-Ten seam was the Yard seam and had a section of top coal between 27 inches to 36 inches, a few inches of dirt, and a bottom coal of between 3 inches to 9 inches. Brunts seam was the Bute seam and was extensively worked at an average thickness of 50 inches. The Upper-Nine-Feet seam was called the Nine-Feet seam in this area and worked at a thickness of up to 78 inches. The Two-Feet-Nine seam was worked at a thickness of 63 inches.

These pits’ coals were generally classed as type 202 Coking Steam Coals, which were weak to medium caking, with an ash content of around 5% to 9%, plus a low sulphur content of around 0.6% to 1.5 %. The main uses were for foundry and blast furnace coke, steam raising and power stations.

Friday, July 14th 1876, the Western Mail reported that a delegation of Northumberland coal workers visited South Wales and described Dare Colliery as; the shaft at this pit is 200 yards deep, and the lower seam is worked. The present output is about 600 tons per day, which however, may be increased to 1,000 tons if necessary…the trams come up with an average of 30 cwt, of coal each, 15 per cent of which is slack.”

The colliery manager in 1878 was R. Reynolds, in 1884 it was Thomas Davies, in 1893 it was William Jenkins and in 1896 it was Alfred Talus. The company continued with further sinkings and in 1887 changed its name to the Ocean Coal Company. It had a capital of £800,000 in 8,000 shares, almost half of them being owned by David Davies and his son, Edward. This company was a member of the Monmouthshire and South Wales Coal Owners Association. In 1908 this colliery was managed by Benjamin Rees in 1913 by W. Morgan and employed 1.012 men and in 1916/20 by M.L. Price. In 1923 the manager was J. Jones who was still there in 1930.

Dare Colliery was served by the Taff Vale Railway, and in 1898 had a sidings capacity for 300 full wagons, 385 empty wagons and 144 other wagons.

In 1930, a 15 foot diameter Waddle type ventilation fan was installed at this colliery.

On the 26th of February 1942 Charles Tuckett, Albert Holmes, John Wynne and J. Phillips died under a huge fall of the roof which also seriously injured three other miners.

On Nationalisation Dare Colliery was placed in the National Coal Board’s, South Western Division’s, No.3 (Rhondda) area and at that time was working the Nine-Feet, Three-Feet-Ten, and No.5 seams, employing 144 men on the surface and 965 men underground. The manager was now E.W. Pomeroy. He was still the manager in 1949. By 1954 it was in the No.3 Areas Group No.4 employing (with Park) 349 men on the surface and 1,887 men underground working the Two-Feet-Nine, Lower-Six-Feet, Upper-Nine-Feet, Lower-Nine-Feet, Bute, Yard, Upper-Seven-Feet, Five-Feet and Gellideg seams.

In 1955, the NCB decided to merge the Dare Colliery with its close neighbour, Park Colliery, the Dare Pit became Park No.3 Pit and Dare’s coal was brought up the Park No.2 Pit. For later information on this merger please see the Park Colliery page.

Some Statistics:

- 1870: Manpower: 678. Output: 177,357 tons.

- 1880: Manpower: 832. Output: 248,460 tons.

- 1889: Output: 214,840 tons.

- 1890: Manpower: 748. Output: 184,402 tons.

- 1894: Output: 324,767 tons.

- 1896: Manpower: 1,200.

- 1899: Manpower: 1,024.

- 1900: Manpower: 1,000

- 1901: Manpower: 955

- 1903: Manpower: 918.

- 1905: Manpower: 1,029

- 1907: Manpower: 1,021

- 1908: Manpower: 1,031.

- 1909: Manpower: 1,031

- 1910: Manpower: 1,064

- 1911: Manpower: 1,049

- 1912: Manpower: 1,165

- 1913: Manpower 1,215.

- 1915: Manpower: 1,165.

- 1916: Manpower: 1,165.

- 1919: Manpower: 1,165.

- 1920: Manpower: 2,124.

- 1923: Manpower: 1,214.

- 1924: Manpower: 1,257.

- 1925: Manpower: 1,214.

- 1926: Manpower: 1,250.

- 1927: Manpower: 1,197.

- 1928: Manpower: 1,286.

- 1929: Manpower: 1,250.

- 1930: Manpower: 1,281.

- 1931: Manpower: 1,280

- 1932: Manpower: 1,340.

- 1933: Manpower: 1,210.

- 1934: Manpower: 1,245.

- 1935: Manpower: 1,234.

- 1937: Manpower: 2,058.

- 1938: Manpower: 1,565.

- 1940: Manpower: 1,660.

- 1941: Manpower: 1,890.

- 1942: Manpower: 2,020.

- 1944: Manpower: 2,050.

- 1945: Manpower: 2,007.

- 1946: Manpower: 2,236.

- 1947: Manpower: 1,888.

- 1948: Manpower: 1,930. Output: 420,000 tons.

- 1949: Manpower: 2,000. Output: 500,000 tons.

- 1950: Manpower: 1,762.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page