Blaen-rhondda, Rhondda Fawr Valley (SS 9268 9894)

Blaen-rhondda, Rhondda Fawr Valley (SS 9268 9894)

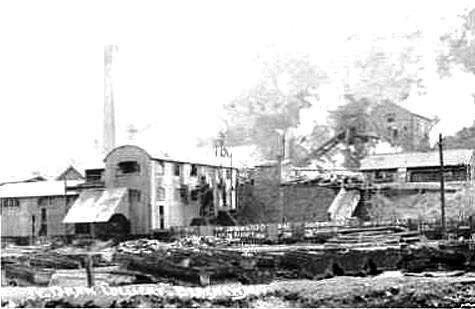

This pit was also called Dunraven Colliery after the company formed by the original owner, Thomas Joseph, the Dunraven United Collieries Company Limited and was situated one mile to the south of the Fernhill’s.

The Earls of Dunraven were Irish landowners who owned considerable tracts of land in South Wales, around 1910 they owned 23,751 acres of land in the South Wales Coalfield which earned them £23,954 in rent for that year.

It was flanked to the north by Fernhill Colliery, to the south by Bute Merthyr Colliery, to the west by Glenrhondda Colliery and to the east by Rhondda Merthyr Colliery.

Some of the seams worked at this colliery were; Lower-Seven-Feet, this seam only had limited workings at a thickness of 27 inches. It was locally called the Five-Feet Rider seam.

The Middle-Seven-Feet seam was known as the Lower-Seven-Feet seam and worked at a thickness of 27 inches.

The Yard seam was called the Seven-Feet seam and worked at a thickness of around 36 inches.

The Bute seam was extensively worked as the Yard seam and had an average thickness of 48 inches.

Also extensively worked was the Upper-Nine-Feet seam which had a thickness of between 66 inches to 78 inches.

This mine was put up for auction on the 9thof September 1858, and was described as;

All that valuable WORKING COLLIERY with all the plant and machinery and buildings thereon (except the cottages and gardens on Building ground sublet) together with the several farms held conjointly therewith, known as the DUNRAVEN COLLIERY… held under leases for the unexpired terms of 58 and 59 years respectively…comprising the whole of the minerals lying under the Hendrewen, Tydraw, Hendregeilin, and portions of Blaenrhondda and Ystradffernol Farms…containing an area of 995 acres…The Abergorchy Seam of Steam Coal is now being worked by two levels, adjoining to, and in connection with the Rhondda Branch of the Taff-Vale Railway. The present output exceeds 160 tons per day, which may at a very moderate outlay be increased to 300 tons per day.

On the 27th of September 1865, the Dunraven United Collieries Company (limited), issued its prospectus. It aimed to raise a capital of £200,000 in 8,000 shares. The directors were; Viscount Malden, Bryan Donkin, David Joseph, George Norton, James Thompson, William Bayliss, George Macdona, John Smith and D. Frazer Luckie. The managing director was Thomas Joseph, he also took £50,000 of the purchase money in share capital with a guaranteed 10% bonus for five years. The aim was to purchase and develop the Dunraven, New Brithdir and Blaenclydach collieries. The Dunraven, it claimed, comprised about 1.000 acres of the well-known Aberdare smokeless steam coal. It is held under leases, of which 50 years are unexpired. It continued to state that the current output was about 120 tons per day but a shaft that was being sunk had now struck the coal and should be completed within that year (it was sunk to a depth of 147 yards to the Two-Feet-Nine seam). The Graig and Abergorki seams were being worked by levels and supplied the locomotive market. In August 1882, Thomas Joseph, the owner, went bust with liabilities of £130,000 and assets of about £30,000. The South Yorkshire Building Society who held most of Joseph’s debts decided to carry on working the mine until a buyer was found.

The Birmingham DailyPost of Monday, 11thof October 1886, reported of a stormy meeting of the South Yorkshire Building Society in which the result was that they would continue working the Dunraven Colliery for a year unless a buyer is found. They themselves were in trouble after giving loans of £100,000 to the colliery company which has failed. The South Yorkshire Building Society put the colliery up for auction in April 1890 starting at £130,000 but received no offers.

It was currently making £7,000 profit a month. It was in January 1891 when the defunct building 5ociety’s shareholders sold the pit, for £26,000 to F.R. Crawshay of Swansea, but alas, he became bankrupt in September 1893.It was again put up for auction in May 1894 but failed to make the reserve price of £10,000. The manager in 1878 was J. Beddows. In 1908 it was Joseph Ritson and in 1918 it was Thomas Williams. It was served by the Taff Vale Railway, and in 1897 it had a sidings capacity of; full wagons, 173 empty wagons and 44 other wagons.

By 1913 it was owned by the Cory Brothers and was now known as Tydraw, in that year it employed 806 men, and was managed by T. Williams (he was still the manager in 1919). With the company advertising:

Cory Brothers & Co.Colliery Proprietors And Sole Shippers of: Cory’s Merthyr Steam Coal. Cory Brothers & Co. Ltd., supply all the Principal Lines of Steamers and are Contractors to the Governments of Great Britain. Germany.France, Italy, Greece, Austria. Brazil. &c Offices and Agents:-Bute Docks. Cardiff. London. Liverpool Paris and Genoa

This Company was a member of the Monmouthshire and South Wales Coal Owners Association.

In 1934 this company was based at Cory’s Building, Cory’s Corner, Cardiff with Sir Clifford J Cory and the general manager, J, Johns the directors of the company. At that time it controlled seven pits producing 1,600,000 tons of coal annually.

In 1923 the manager wasW.T. Jones and 1930-5 Tydraw Colliery was managed by H. Thompson (he was the manager in 1927) and employed 115 men working on the surface of the mine and 740 men working underground. It remained in the hands of the Cory Brothers until Nationalisation. In 1938 it was still managed by H. Thompson but by 1945 the manager was D.S. Evans.

In 1943 it employed 375 men working underground in the Gorllwyn, Nine-Feet and Five-Feet seams and 108 men working at the surface of the mine. In 1944 water infusion in the Chambers District reduced airborne dust by 56%. This coalface was in the Five-Feet seam and was 42 inches thick. It was 100 yards long with a jigger type coalface conveyor and the coal was hand filled by twelve men who produced 60 to 70 tons of coal a shift. A jigger was a form of coal conveyor in which deep pans ‘jigged’ back and forwards shaking the loaded coal towards the end of the coalface.

In 1955 out of the total colliery manpower of 392 men, 203 of them worked at the coalfaces, in 1956 this coalface figure was 185 men, in 1957 the coalface figure was 162 men, while in 1958 there were 153 men working at the coalfaces of this mine. In 1956 the price list for the five feet thick Six-Feet seam was three shillings and nine pence per square yard of hand cut and filled clean coal.

On closure in January 1959 this colliery employed 55 men on the surface and 278 men underground. The reason for the closure was stated by the NCB as “economy”.

Dunraven pits and levels:

- 17/4/1867, William Thomas, aged 16, collier, roof fall.

- 19/4/1867, David Howells, aged 22, collier, roof fall.

- 15/5/1869, James Rees, aged 53, collier, roof fall.

- 28/5/1869, David Rees, aged 50, hitcher, shaft incident.

- 11/10/1869, D. Jones, aged 36, collier, roof fall.

- 3/4/1871, P. Jones, aged 55, hitcher, roof fall.

- 10/4/1872, William Harvard, aged 41, collier, roof fall.

- 16/8/1872, D. Jones, aged 15, collier, roof fall.

- 30/6/1873, Evan Llewellyn, aged 15, haulier, roof fall.

- 16/9/1874, G. House, aged 50, collier, run over by trams.

- 5/10/1875, J. Dawkins, labourer, run over by trams.

- 26/12/1876, J. Morgan, collier, roof fall.

- 19/5/1877, Thomas Hughes, aged 25, collier, scalded.

- 9/12/1877, E. Radford, aged 44, furnaceman, fell down the shaft.

- 22/1/1880, David Roberts, aged 13, collier boy, roof fall.

- 8/4/1881, Joseph Thomas, aged 15, collier boy, roof fall.

- 2/12/1882, Evan Edwards, aged 26, rider, run over by trams.

- 17/8/1883, W. Watkins, aged 22, haulier, run over by trams.

- 24/11/1883, W.Thomas, aged 23, collier, roof fall.

- 28/12/1883, J. Williams, aged 41, collier, run over by trams.

- 25/7/1884, Henry Clarke, aged 37, hitcher, run over by trams.

- 7/1/1885, Thomas Davies, aged 49, labourer, run over by trams.

- 7/3/1885, David Hicks, aged 51, haulier, run over by trams.

- 28/11/1885, Sidney Davies, aged 27, hitcher, crushed by trams.

- 5/1/1887, William Buckland, aged 24, hitcher, crushed by the cage.

- 14/6/1887, Thomas Jones, aged 48, collier, roof fall.

- 6/10/1886, John Evans, aged 27, collier, roof fall.

- 10/10/1886, David Rees, aged 49, fireman, fell down the shaft.

- 26/1/1887, David Davies, aged 24, collier, roof fall.

- 31/5/1887, Ebenezer Evans, aged 68, collier, roof fall.

- 2/8/1887, Gower Morris, aged 18, rider, crushed by trams.

- 24/6/1888, John Williams, aged 27, engineman, roof fall.

- 30/6/1888, James Williams, aged 17, haulier, crushed by trams.

- 21/2/1890, Daniel Price, aged 20, engineman, machinery.

- 9/9/1889, W. R. Evans, aged 15, collier boy, roof fall.

- 26/3/1890, Thomas Walters, aged 62, smith, machinery.

- 6/8/1891, Thomas Bowen, aged 50, fireman, Frederick Smith, aged 39, ripper, fell down the shaft.

- 27/8/1891, William Saxon, aged 20, haulier, run over by trams.

- 2/9/1891, John S Thomas, aged 13, collier boy, roof fall.

- 22/1/1892, John Walters, aged 18, collier, roof fall.

- 17/10/1892, William Morgan, aged 74, labourer, roof fall.

- 1/12/1892, Samuel Samuel, aged 57, collier, roof fall.

- 23/2/1894, William Thomas, aged 24, collier, roof fall.

- 27/3/1895, David Price, aged 57, collier, roof fall.

- 22/12/1898, Thomas Pole, aged 60, collier, roof fall.

- 29/7/1899, Henry Dobbs, aged 41, collier, shotfiring incident.

- 15/4/1910, John Owen, aged 51, collier, roof fall.

Some Statistics:

- 1899: Manpower: 201.

- 1900: Manpower: 201.

- 1901: Manpower: 188.

- 1902: Manpower: 201.

- 1903: Manpower: 408.

- 1907: Manpower: 662.

- 1908: Manpower: 730.

- 1909: Manpower: 730.

- 1910: Manpower: 747.

- 1911: Manpower: 777.

- 1912: Manpower: 799.

- 1913: Manpower: 806.

- 1915: Manpower: 930.

- 1918: Manpower: 814.

- 1920: Manpower: 969.

- 1923: Manpower: 1,048.

- 1924: Manpower: 1,127.

- 1925: Manpower: 1,120.

- 1926: Manpower: 1,000.

- 1927: Manpower: 871.

- 1928: Manpower: 815.

- 1929: Manpower: 786.

- 1930: Manpower: 870.

- 1931: Manpower: 870.

- 1933: Manpower: 980.

- 1934: Manpower: 969.

- 1935: Manpower: 855.

- 1936: Manpower: 855.

- 1937: Manpower: 800.

- 1938: Manpower: 558.

- 1940: Manpower: 600.

- 1941: Manpower: 500.

- 1942: Manpower: 380.

- 1944: Manpower: 438.

- 1945: Manpower: 483.

- 1947: Manpower: 383.

- 1948: Manpower: 450. Output: 100,000 tons.

- 1949: Manpower: 520. Output: 158,000 tons.

- 1950: Manpower: 477.

- 1953: Manpower: 447. Output: 136,100 tons.

- 1954: Manpower: 383. Output: 92,000 tons.

- 1955: Manpower: 392. Output: 78,143 tons.

- 1956: Manpower: 387. Output: 63,993 tons.

- 1957: Manpower: 379. Output: 74,656 tons.

- 1958: Manpower: 358. Output: 52,766 tons.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page