Nantymoel, Ogmore Valley (SS 9336 9207)

Nantymoel, Ogmore Valley (SS 9336 9207)

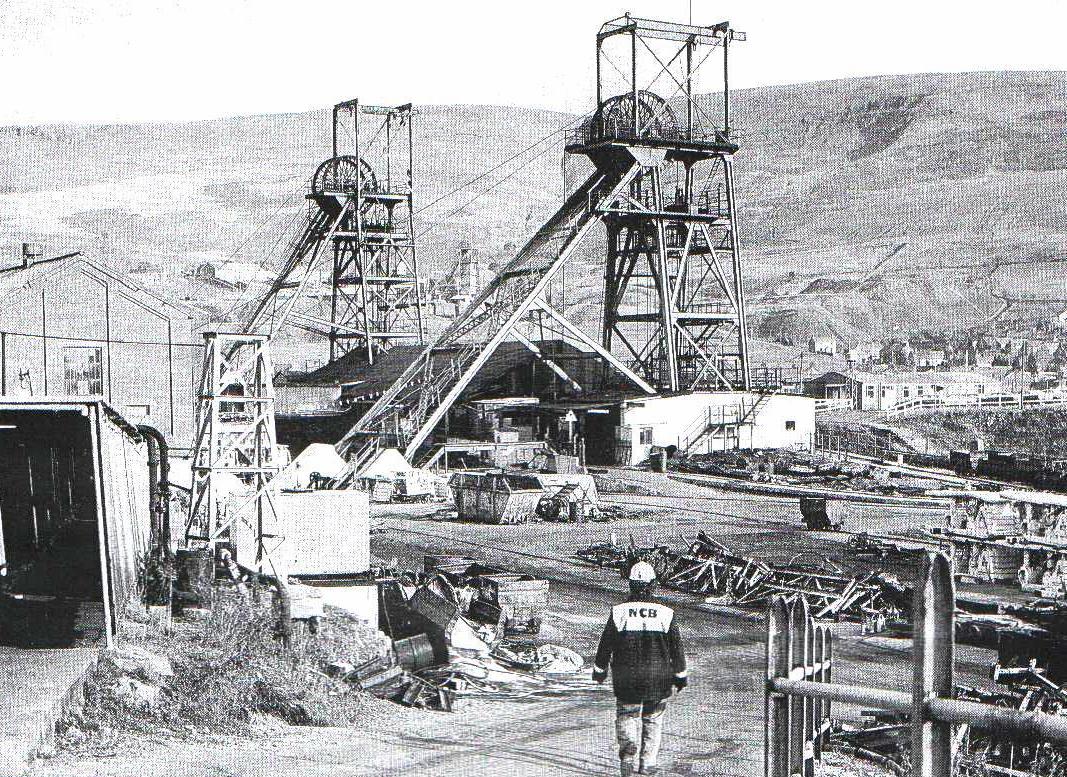

Wyndham Colliery was eight miles to the north of Bridgend and was sunk in 1865 by the Llynvi, Tondu and Ogmore Vale Iron and Coal Company, and was managed in 1878 by J. Jones.

The sinking of the two shafts to the Six-Feet seam was completed in 1868 but they were deepened in 1891 to just below the Bute seam to a depth of 1,076 feet 11 inches. The shaft diameters were 15 feet and 12 feet. Some of the seams worked at this colliery were; The Gellideg seam at a thickness of 48 inches. The Five-Feet seam had a thickness of coal 52 inches, dirt 9 inches, coal 11 inches, dirt 3 inches, coal 24 inches, dirt 3 inches, coal 6 inches. The Yard seam was worked as the Seven-Feet seam and had a thickness of around 61 inches. The Bute seam was extensively worked as the Yard seam and had a thickness of up to 66 inches. The Lower-Nine-Feet seam was also extensively worked as the Bute seam and had a thickness of 59 inches. The Caerau seam was extensively worked and called the Red Vein at this pit. It had a thickness of 71 inches. The Lower-Six-Feet seam was extensively worked at a thickness of between 66 inches to 84 inches. Also extensively worked was the Two-Feet-Nine seam which had a thickness of top coal, 48 inches to 60 inches, dirt band of between 6 inches to 42 inches, bottom coal of between 12 inches to 8 inches. There was also a Wyndham Level that worked the No.3 Rhondda seam at a thickness of 28 inches.

On October 30th 1882 dispute over a change in medical attendants went in the men’s favour. The men went out on strike without giving notice, so the company summonsed twenty of them and also issued notices to throw them out of their houses. In the end, the company and the men withdrew their threats and things went on as before.

The Western Mail of Thursday 25th September 1890 reported:

On Tuesday night, while a number of men were riding in the trams to work at a remote district in the Wyndham Colliery, Ogmore Valley, the trams ran wild, and came in contact with a number of posts, which fell, instantly killing one man named Samuel Elstone, commonly known as ‘Sam Pippin’ and seriously injuring his nephew, Elias Pippin, who now lies in a critical condition. The deceased was removed to his late lodgings, pending the inquest, when his body will be removed to Bridgend, where his widow and children reside.

This company became bankrupt in 1888 was bought by a group of businessmen, headed by Colonel J.T. North, for £350,000. The new company acquired a capital of £450,000 and was eventually called North’s Navigation Collieries (1899) Limited. In 1893 it was managed by David Sims Rees and in 1896 it was managed by John Jones. Wyndham Colliery was sold to the Cory Brothers Limited in 1906, who by 1913 employed 1,395 men at Wyndham Colliery, the manager in 1908/1930 was D. Llewellyn Richards. This company advertised in 1913:

Cory Brothers & Co. Limited Colliery Proprietors and sole shippers of Cory’s Merthyr Steam Coal Cory Brothers & Co., Ltd., supply all the principal Lines of Steamers, and are Contractors to the Governments of Great Britain, Germany, France, Italy, Greece, Austria, Brazil, &c Offices and Agents – Head Office: Bute Docks, Cardiff. London: 3, Fenchurch Street. Glasgow: 125, Buchanan Street Liverpool: 22 Water Street. Paris: 48, Rue De La Victoire. Genoa: 2, Via Ponte Reale.

This company was a member of the Monmouthshire and South Wales Coal Owners Association.

On the 6th of June 1929, The Times reported that owing to influenza among pit horses the management are experiencing great difficulty in keeping the colliery going.

In January 1930 a novel way of making the men aware of the dangers of mining was installed. As the cage descended from the pit-top, a recording of the manager’s voice warned them of the various perils that they faced.

In 1935 Wyndham Colliery employed 163 men working on the surface and 1,267 men working underground. The manager was still DL. Richards.

In September 1937 a rat short-circuited the electrical supply to this pit closing down the ventilation fan for several hours. The men were getting ready to leave the pit when the power was restored.

In 1942 this colliery came under the control of the Powell Duffryn Steam Coal Company Limited who in 1943 replaced steam with electricity as the main means of power. It was in July 1942 that this colliery possessed the first miner’s canteen in South Wales that gave a full hot meal service. Meat, two vegetables, sweet and tea cost ten pence. In 1943/5 the manager was D. Ferguson and the No.1 Pit employed 380 men underground working the Yard and Two-Feet-Nine seams while the No.2 Pit worked the Nine-Feet, Yard, Two-Feet-Nine and “D” seams and employed 393 men working underground. There were 182 men employed at the surface of the mine.

In 1944 seven colliers from this colliery were fined between £5 and £11 for going on a ‘go slow’ despite the war effort.

On Nationalisation of the Nation’s coal mines in January 1947, Wyndham Colliery was placed in the National Coal Board’s, South Western Division No.2 Area, Ogmore Group and at that time employed 135 men working on the surface of the mine and 711 men working underground with the No.1 Pit working the Yard and Two-Feet-Nine seams, and the No.2 Pit the Nine-Feet, Two-Feet-Nine, Seven-Feet, Bute and ‘A’ and ‘D’ seams. The manager was T. Thomas or possibly E.G. Thomas who was the manager in 1949. The same seams are being worked in 1954 with the No.1 Pit employing 392 men working underground, and the No.2 Pit employing 395 men working underground with 138 men employed on the surface of the colliery. The manager was now D.E. Hughes. By 1955 the coal from the Two-Feet-Nine and Bute seams was being worked from the downcast shaft and the Lower-Nine-Feet, Seven-Feet and Gellideg seams were being worked from the upcast shaft. In 1955 out of the total colliery manpower of 884 men, 426 of them worked at the coalfaces. In 1958 these figures were 845/373 respectively.

In August 1950 a machine called the Samson Stripper was installed on a coalface in the Bute Seam at Wyndham. It was the first of its type in South Wales. The face was 300 yards in from pit-bottom and 70 yards long, with the seam being four feet thick. The Samson Stripper consisted of chisel-shaped wedge heads that would cut 25 inches of coal along the coal face, a vertical jack would secure the propulsion which was by hydraulics from a 20 h.p. motor that operated the ten-ton machine. It took 15 minutes to cut the face. Cutting was only done on the dayshift where five men were employed; two on the machine, two putting roof supports and a maintenance man. Packing of the roadways was done on afternoons and the advancing of the roadways by the night shift.

In 1957/65 at a cost of £3 million Wyndham Colliery was merged with the neighbouring Western Colliery with the estimated reserves for the combine given as:

- Two-Feet-Nine seam 4.0 million tons

- Upper-Nine-Feet seam 8.6 million tons

- Lower-Nine-Feet seam 8.0 million tons

- Bute seam 3.2 million tons

- Yard seam 7.8 million tons

- Upper-Seven-Feet 9.3 million tons

- Lower-Seven-Feet 1.5 million tons

- Five-Feet seam 10.7 million tons

- Gellideg seam 8.7 million tons

- Total 62 million tons of coal

During the re-organisation, the Wyndham downcast shaft was deepened by 120 yards to a depth of 435 yards and the Western upcast shaft deepened to a depth of 476 yards. A 315 yards long roadway was driven to connect the pits, which was completed in 1962. Two new winders (600 h.p. and 1,700 h.p.) and headgear were installed at Western and a new winder was installed at Wyndham No.1 Pit. Western Colliery’s coal was taken by underground conveyors to a bunker 1,300 yards from the Wyndham pit bottom and from there shunted by one of three 65 h.p. diesel locomotives. The Wyndham shaft was easily capable of winding the target of 15,000 tons of coal per week. The cages were double deck and could wind 28 men or 3 tonnes of materials per wind. All supplies for the complex were taken down the Western side. The N21 coalface was started in 1965 and by 1968 it had travelled 1,840 yards. This face was hand filled with sixty men working the three shifts, the method of support was by eight feet Huwood serrated bars and Dowty props in conjunction with Wilde 50-100 powered supports.

The face conveyor was a panzer that was moved over after the coal had been filled. The width of coal taken was 30 inches per shift with double shift coaling. The length of the face was 160 yards with the colliers stents being 25 feet. The price list was 52 pence per square yard for a seven feet thick seam. In 1969/78 the manager was R. Walker and in 1979+ it was A.J. Reed. In 1971 the combine employed 1,188 men and produced 475,000 tons of coal, the largest output of any unit in the South Wales Coalfield. The pits were then working the Bute, Five-Feet and Gellideg seams.

Towards the end of the 1970s the area being worked was 16 square miles of the Bute and Gellideg seams to a depth of 2,000 feet. There were 8 miles of roadways, five miles of conveyors and one mile of locomotive plane. Output per man shift at the coalfaces (there were two workings) was 4.5 tonnes, and overall for the colliery the output per man shift was 1.2 tonnes.

In c1978 the NCB invested £1.7 million to open up another area of the Five-Feet seam. In 1981 the Wyndham/Western Colliery was working the Five-Feet seam at a thickness of between 1.45 and 1.52 metres, with coalface length varying from between 130 metres to 200 metres. The Lower-Six- Feet seam was also being worked and had a thickness of 1.5 metres and a coalface length of 200 metres. All coal cutting was done by ranging drum shearers and all coalface roof supports were the self-advancing types. Colliery output per day was expected to be 930 tonnes of coal with output per manshift at the coalface set at 4.91 tonnes and overall for the colliery at 1.51 tonnes. The saleable coal yield was 65% of the total production. The coalfaces in the Five-Feet seam were prefixed by the letter K, with the K3 advancing 1.2 metres per single coaling shift a day with an expected life of 1,000 metres in February 1981. This coalface was replaced by the K4 which had a life of 700 metres. The K51 was started in June 1981 and had a life of 700 metres with a daily advance of 1.1 metres.

Manpower deployment was:

- working on developing new coalfaces 108 men.

- working on existing coalfaces 174 men.

- working on other jobs underground, 200 men.

- working at the surface of the mine 105 men.

The manager was M. J. Goldsworthy.

In 1981 the NUM Lodge made a claim for extra clothing in the form of flannel suits for their men working near the bottom of the pit due to the cold in that area. A joint NUM/NCB investigating team agreed to give the suits to hitchers, shacklers, loco men and shaftsmen. Extra overalls were agreed for men on supplies, fitters, electricians, roadmen, greasers and bunker operators. All were in receipt of donkey jackets.

The NCB announced the closure because of hopeless mining conditions. The 537 miners were offered alternative jobs or redundancy and Wyndham/ Western Colliery was closed in January 1984.

Just some of the men who died at this pit:

- 2/3/1868, Robert Thomas, aged 29, labourer, roof fall.

- 13/4/1872, Jenkin Jenkins, aged 25, collier, roof fall.

- 3/2/1875, Thomas Williams, carpenter, explosion of gas.

- 29/1/1877, William Jones, aged 16, collier, roof fall.

- 25/4/1877, John Hart, collier, roof fall.

- 24/8/1877, Evan Jenkins, aged 38, labourer, shaft incident.

- 9/5/1879, John Lewis, aged 13 door boy, run over by trams.

- 2/8/1879, Robert Jones, aged 43, collier, roof fall.

- 30/6/1880, Richard Owen, aged 16, labourer, crushed by surface wagons.

- 19/5/1882, Richard Harding, aged 29, haulier, fell down shaft.

- 26/9/1884, William Staple, aged 36, jobber, roof fall.

- 22/1/1885, Henry Harris, aged 28, rider, run over by trams.

- 5/5/1885, Hopkin Evans, aged 20, haulier, roof fall.

- 12/6/1885, W.E. Richards, aged 54, collier, roof fall.

- 17/12/1885, James Martin, aged 33, haulier, roof fall.

- 14/4/1886, John Williams, aged 39, repairer, roof fall.

- 11/8/1887, John Snow, aged 25, repairer, roof fall.

- 31/8/1887, John Ham, aged 52, labourer, roof fall.

- 26/1/1888, Israel Jones, aged 18, haulier, roof fall.

- 29/8/1888, William Williams, aged 28, haulier, crushed by trams.

- 14/1/1892, Fred Bowden, aged 18, brakes man, crushed by surface wagons.

- 9/4/1892, John Richards, aged 44, engineer, fell down the shaft.

- 29/7/1893, John Lewis, aged 38, collier, roof fall

- 28/10/1893, Henry Boundy, aged 21, brakes man, crushed by surface wagon.

- 19/4/1895, William Male, aged 30, brakes man, run over by surface wagons.

- 25/7/1895, William Turner, aged 48, collier, roof fall.

- 23/11/1895, John Bridges, aged 31, collier, run over by trams.

- 10/1/1898, William Evans, aged 32, rider, run over by trams.

- 15/10/1910, William Edwards, aged 53, fitter, run over by trams.

- 13/9/1911, John Gough, aged 30, repairer, roof fall.

- 20/7/1913, Thomas Pryce, aged 32, collier, roof fall.

- 11/9/1914, William Williams, aged 69, cleaner, run over by trams.

- 24/3/1926, W. Popples, aged 66, shackler, run over by trams.

- 10/2/1928, Hugh Samuel, aged 41, collier, roof fall.

- 19/2/1929, Norman Fisher, aged 38, repairer, run over by trams.

- 19/6/1929, O. Jenkins, aged 26, haulier, roof fall.

- 25/10/1930, Abel Williams, aged 56, collier, roof fall.

Some Statistics:

- 1889: Output: 179,606 tons.

- 1899: Manpower: 877.

- 1900: Manpower: 1,008.

- 1901: Manpower: 1,035.

- 1902: Manpower: 1,071.

- 1905: Manpower: 1,246.

- 1907: Manpower: 1,103.

- 1908: Manpower: No.1 Pit: 556. No.2 Pit: 554. Surface: 169.

- 1909: Manpower: 1,279.

- 1910: Manpower: 1,345.

- 1911: Manpower: 1,250.

- 1912: Manpower: 1,280.

- 1913: Manpower: 1,395.

- 1915/6: Manpower: 1,326.

- 1918: Manpower: 1,332.

- 1919: Manpower: 1,326.

- 1920: Manpower: 1,631.

- 1922: Manpower: 1,228.

- 1923: Manpower: No.1 Pit: 691. No.2 Pit: 560. Surface: 194.

- 1925: Manpower: 1,362.

- 1927: Manpower: 1,424.

- 1928: Manpower: 1,366.

- 1929: Manpower: 1,363.

- 1930: Manpower: 1,442.

- 1931: Manpower: 1,492.

- 1933: Manpower: 1,406.

- 1935: Manpower: 1,430.

- 1937: Manpower: 1,195.

- 1938: Manpower: 1,166.

- 1940: Manpower: 1,150.

- 1942: Manpower: 950.

- 1944: Manpower: 973.

- 1945: Manpower: No.1 Pit: 380 No.2 Pit: 395. Surface: 182.

- 1947: Manpower: 925.

- 1948: Manpower: 906. Output: 230,000 tons.

- 1949: Manpower: 850. Output: 230,000 tons

- 1950: Manpower: 846.

- 1953: Manpower: 912 Output: 285,000 tons.

- 1954: Manpower: 846. Output: 243,974 tons.

- 1955: Manpower: 884. Output: 229,425 tons.

- 1956: Manpower: 878. Output: 208,830 tons.

- 1957: Manpower: 891. Output: 207,513 tons.

- 1958: Manpower: 845. Output: 200,376 tons.

- 1960: Manpower: 900. Output: 199,534 tons.

- 1961: Manpower: 848. Output: 199,615 tons.

- 1964: Manpower: 879.

- 1969: Manpower: 1,263.

- 1971: Manpower: 1,188. Output: 475,000 tons.

- 1972: Manpower: 1,186.

- 1974: Manpower: 1,112.

- 1975: Manpower: 1,069.

- 1976: Manpower: 1,186.

- 1978: Manpower: 1,095. Output: 250,000 tons.

- 1979: Manpower: 914. Output: 144,000 tons.

- 1981: Manpower: 670.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page