Coedely, Llantrisant (ST 0156 8613)

Coedely, Llantrisant (ST 0156 8613)

The Welsh Navigation Steam Coal Company Limited was a subsidiary company of David Davis and Sons Limited and was incorporated in 1906, with its headquarters at Cambrian Buildings, Cardiff. It employed 96 men underground and 135 men on the surface at Coedely in 1908, the manager was Griffith Jones.

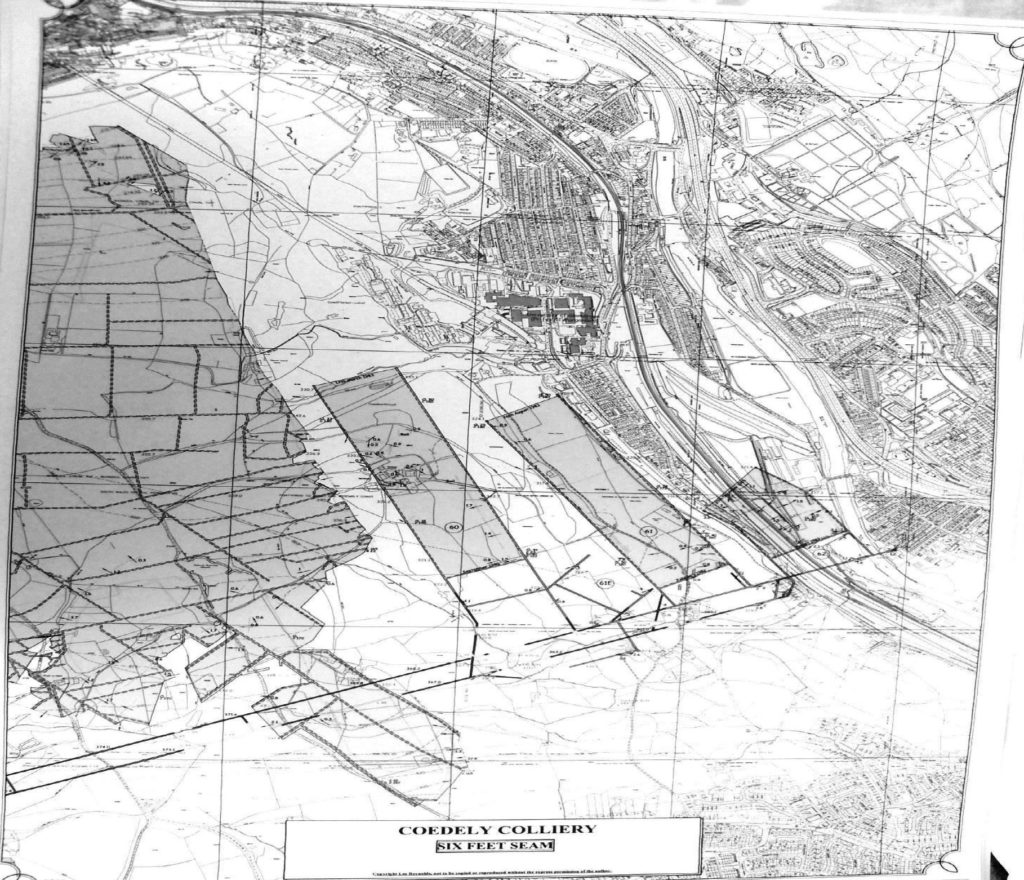

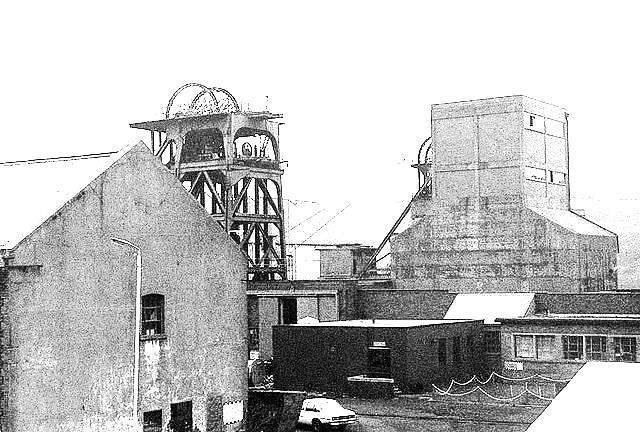

The No.1 Pit of this colliery was located 2,330 yards south of St. David’s Church, Tonyrefail at NGR 01568613 sheet ST08NW, 345 feet OD. It was 40 yards from the No.2 Pit and was sunk between 1901 and 1906 by the Welsh Navigation Steam Coal Company. It was closed by British Coal in 1985.

The Two-Feet-Nine seam was known as the Pentre at this pit and was extensively worked at a thickness of 54 inches. Also extensively worked was the No.3 Rhondda seam at a thickness of 30 inches. The No.2 Rhondda seam was worked at a thickness of 48 to 51 inches. Generally, the coals of this colliery were classed as type 301B Prime Coking Coals for use as foundry or blast furnace coke and were processed at the colliery’s own coking plant.

In 1910 a Walker type ventilating fan was installed at this colliery, it was 20 feet in diameter and 7 feet wide.

The Times, on Wednesday, April 2nd 1913, reported that:

The Coppee Company (Great Britain) (Limited) are building for the Welsh Navigation Steam Coal Company of Ferndale at the Coedely Colliery, Llantrisant, a 750 ton coal washery and 60 regenerative ovens, together with by product plant for tar, sulphate of ammonia, and crude and rectified benzol. The scheme includes a 1,000 ton coal storage bunker and an aerial ropeway 1,400 yards long, having a capacity of 60 tons an hour, complete with a 440 ton bunker, tippers, &c., for dealing with the refuse from the pit and washery and conveying fireclay to the company’s new brickworks.

In 1913 the pit employed 1,003 men, advertising their wares thus:

Welsh Navigation Steam Coal Company Ltd Proprietors – D. Davis & Sons Ltd.

Proprietors and Shippers of Coedely – No.2 Rhondda Coal. For Bunkering and Manufacturing. No.3 Rhondda Coal. High Class Smith’s and Coking Coal.

Bituminous Large Coal. Hard and Free from Small.

Shipping Ports: Cardiff Barry, Penarth, Port Talbot, Swansea and Newport

Registered Office: Cymric Buildings, West Bute Street, Cardiff London Office: 138, Leadenhall Street, E .C Paris Office: 22, Rue St. Agustin

In 1915 the Business Statistics Company published a book called the South Wales Coal and Iron Companies which reported that D. Davis & Sons Limited:

was formed in 1890 to purchase the Ferndale and Bodringallt Collieries, and in 1894 acquired the Tylorstown Collieries. The properties are known as the Ferndale and comprise nine winding pits, all situated in the Rhondda Valleys. The Company has acquired the entire Share Capital of the Welsh Navigation Steam Coal Co, Ltd (the Proprietors of the Coedely Collieries) for the sum of £314,850 and nine-tenths of the share capital of John Lancaster and Co, Ltd, a company owning collieries in Monmouthshire. The annual output of the Welsh Navigation Steam Coal Co, Ltd is about 400,000 tons, and of John Lancaster and Co, Ltd about 1,300,000 tons.

The book continued to state that the company had assets of £1,110,918 and had made a profit of £2,291,427 between 1889 and 1914. The board of directors at that time were; Frederick Lewis Davis, Chairman, David Hannah, Jules Vasse, Thomas Vivian-Rees, Harry Leonard Warner and John Bell White. In 1915/19 the manager was S. Davies.

In June 1930 the newspapers reported:

ENTOMBED FOR 16 HOURS GALLANT RESCUE OF TWO MEN IN PIT ALL-NIGHT TASK From Our Own Correspondent TONYPANDY, Monday. After a 16 hours’ ordeal facing slow death from suffocation. two officials at Coedely Colliery, Tonyrefail, entombed behind huge fall of roof, were rescued today exhausted but unharmed. They owe their lives to the heroic efforts of hundreds of workers, who tolled in relays under the crumbling roof to extricate their colleagues. The two men. Hubert Clarke, surveyor, of Collena-roud. Tonyrefail. and T. W. Rees, fireman, Pengarreg-11 road descended the mine early yesterday. When they did not return at 5 o’clock the banksmen descended and discovered fall had occurred. Within a few minutes of hearing the news, hundreds of men, many in their best clothes, volunteered for the hazardous work rutting way through rescue them. They toiled all night regardless of the peril threatening their own lives.

VOICES About 10 o’clock they discovered the missing men were alive, and a little later heard them calling faintly for water. Working with renewed vigour they were able soon after to make an air passage the unfortunate men. and later passed stimulants through a small aperture. The work became increasingly dangerous. and eventually, only one man at a time was able to work his way through the tunnel. Just before o’clock the officials were extricated, dazed but uninjured. Anxious parents and friends kept vigil at the pithead throughout the night.

In 1935 this colliery operated 30 coke ovens, a coal preparation plant and a by-product works, but manpower had dropped from 1,201 in 1923 to 263 men on the surface and 570 men underground producing steam, house and manufacturing coals from the bituminous seams. The manager at that time was W. Griffiths. The chairman of the company at that time was David Hannah. In 1938 the manager was still W. Griffiths and he was still there in 1943 when the colliery employed 783 men working underground in the Pentre and No.3 Rhondda seams, and 198 men working at the surface of the mine. The problem of keeping miners in Coedely, and the coalfield’s during the war years was so severe that in 1944 the government was forced to direct labour into the collieries of the United Kingdom. For the South Wales Coalfield as a whole manpower/production fell from 128,774 men and 35,269,000 tons in 1939 to 107,624 men and 20,954,000 tons in 1946, all this at a time when coal was at a premium, so much so that in 1942, once again, the government took control of the nation’s coal

Along with the Nation’s other coal mines Coedely was Nationalised in 1947 and was placed in the National Coal Board’s South Western Divisions No.3 (Rhondda) Area which was based at Treorchy. At that time the pit was working the Pentre. Lower Pentre and No.2 Rhondda seams employ 166 men on the surface and 788 men underground producing coking and house coals. At that time the manager was W.M. Griffiths. He was still the manager in 1949.

By 1954 the colliery was working the Two-Feet-Nine, No.2 Rhondda and Lower-Four-Feet seams employing 132 men on the surface and 704 men underground being placed in the No.2 Group of Area No.3. The manager was J.H. Jones. Such was the demand for coke it was decided to invest £400,000 in constructing 70 new coke ovens at Coedely.

In the mid to latter 1950s, it was evident that Coedely Colliery was not yielding the results in production that would enable it to survive, see the table below.

THE ANNUAL OUTPUT PER MAN (in tons)

1955 – 192.75.

1956 – 170.41.

1957 – 209.25.

1958 – 213.49.

1961 – 198.64

In 1955 this colliery employed 416 men working at the coalfaces, in 1956 this figure had dropped to 384 men, further dropping to 333 men in 1958.

On the 6th of June 1956 their afternoon shift over, twenty men entered the cage at pit bottom, started to rise, and they were stuck in the shaft for two hours due to rain fusing an electrical circuit in the winding engine.

In 1958 Coedely merged with Cwm Colliery to create the largest colliery in the South Wales Coalfield. At that time Coedely was working the Gorllwyn seam and produced 66% of the Combines output, its workings were 6,000 yards from Cwm’s Shafts. It was planned to raise 5,500 tons of prime coking coal every day from a reserve estimated at 150 million tons. Manpower was planned at 3,000 men.

Five workable seams occurred within a vertical depth of 120 yards and it was anticipated to mine them all, working the top seams first and transferring the coal by spiral shutes to the bottom seam where double-ended diesel locomotives worked on roadways that were 16 feet wide and 13 feet high.

In all, there were 16 staple pits, the deepest 120 yards. The third northwest level was the link up to Coedely. Stations to load up to 2,000 tons daily will be at the bottom of each spiral chute, Six-ton capacity box type cars, the largest in the U.K. are hauled, twenty at a time, by diesel locomotives of 102 h.p. and fifteen tons in weight, with a top speed of 7 m.p.h. From the mine car, the coal goes to a rotary tippler and then an elevated conveyor takes it to two skips in the shaft of 12 tons capacity each. The shaft can wind 600 tons an hour. The skip winding plant is believed to be the largest in the world and is driven by a 3000 h.p. motor. The construction of the massive Coke Works was also started around this time and completed in 1958. In 1981 another £20,000,000 was invested in this work which then gave employment to 300 men and produced 325,000 tonnes of coke.

The 900 h.p. surface fan was capable of producing 450,000 cubic feet of air every minute. While the shaft pumps pumped up the pit 120,000 gallons of water every day.

The Times newspaper of the 14th of March 1967 reported:

In spite of a stern letter from the National Coal Board and miners’ leaders that unless absenteeism falls their colliery will be closed, about 450 of the 1,500 men employed at the Cwm Colliery near Pontypridd, failed to report for work today. The men have been told that the £8m, showpiece pit, where lost production costs £10,000 a week, may close because of their absenteeism, which is high on the afternoon shift and especially on Monday mornings.

The men employed at the pit live over a wide area and many of them have been transferred from pits that have closed.

Mr. Bryn Williams, NUM lodge secretary, said today; ‘This absenteeism is very worrying. If the colliery is closed there will be disastrous consequences for the men, 400 of whom live in the Rhondda where the unemployment rate is already 9 per cent’

In 1969/70 the manager was T. Pugh, with, at that time, it was working the Six-Feet, Lower Nine-Feet, Bute and Yard seams while the Coedely section was working the Six-Feet and Yard seams. In 1971/80 the manager was B. Williams. In 1964 the NUM Lodge Secretary was B. Williams, and in 1977, 1978 and 1981 it was Luther Lodwig.

In October 1973 the NUM members took umbrage at the under-manager swearing at them and went on unofficial strike for three days.

In 1974 the market for coking coals in South Wales stood at 4.6 million tons a year, the NCB predicted that this figure would rise to between 5.5 and 6.5 million by 1980. To increase the output of coal from the coking coal pits the NCB made certain proposals including driving two 1,600 metre drifts from existing workings into an area east of the pit in which boreholes had proved a reserve of 9 million tons. One road would be for the trunk conveyor and the other a locomotive road for transporting men and materials. The cost was estimated at £2 million with a projected annual output of 550,000 tons and an output per manshift of 36.6 tons.

In 1978 there were six coalfaces in operation giving an output per manshift of 5.1 tonnes on the coalface and of 1.38 tonnes overall. The seams being worked were the Yard, Six-Feet and Five-Feet. At that time the colliery’s mineral take was around eight miles square with fifteen miles of roadways and six miles of conveyors in use. Further investment of £2.7 million was put into the combine to drive roadways into new reserves.

In 1981 Cwm/Coedely worked five coalfaces in the Five-Feet and Six-Feet seams. The Six-Feet seam had a section of between 1.35 metres and 1.82 metres, and the Five-Feet seam was with a section of between 1.48 metres and 1.6 metres. Coalface length varied from between 120 metres and 200 metres, with coal cutting by ranging drum shearers and coalface roof support by the self-advancing type. The expected output per manshift on the coalface was 6.64 tonnes, and overall 1.96 tonnes.

The saleable yield of coal was 70% of the total output. Manpower deployment was; development 232, coalfaces 329, others underground 387, on the surface of both mines, 218. The manager was still B. Williams.

The coalfaces in the Six-Feet seam were prefixed by a “6” or a “4” with the 630 coalface closing in July 1981 having advanced at an expected rate of 1.5 metres per day on a double shift basis. This face was replaced by the 631 coalface which was to advance at a rate of 1.24 metres on double shift producing 600 tonnes a day and having a life of 390 metres. The 60 coalface was expected to advance at a rate of 1.64 metres on a double shift basis producing 600 tonnes per day and closing in February 1982. It was to be replaced by the 61 coalface which was expected to advance at a rate of 1.43 metres on double shift also producing 600 tonnes a day with a life of 630 metres. The 481 coalface advanced at a rate of one metre per day on double shift giving a daily tonnage of 450; it was expected to close in September 1981. This one was to be replaced by the 482 coalface which had a life of 500 metres with a daily output of 350 tonnes. In the Five-Feet seam the coalfaces were prefixed by a “5” with the 504 advancing at a rate of one metre per day on a single shift producing 350 tons a day and closing in July 1981. It was to be replaced by the 505 coalface which was also expected to advance one metre per day. This coalface had a life of 600 metres.

In 1983 Cwm/Coedely Colliery was losing £7.80 for every tonne of coal that it produced and employed 1,274 men. Meanwhile the NCB yesterday confirmed the closure the Coedely coke works in South Wales “as soon as possible” The decision could mean a confrontation today between board chairman Mr MacGregor, and miners’ president Mr Arthur Scarglll They are due to meet at a meeting of the board’s consultative council, in London.

Following the return to work after the 1984-85 miners strike, this colliery had a disappointing start, and by the end of April there were still adverse roof conditions affecting the 482 and 634 coalfaces, and the 62 coalface had yet to produce a single tonne of coal due to a roadway crush. The results from the other two coalfaces, the 505 and 506 were disappointing and total output only reached 64% of expected levels.

Following the strike attempts to develop the Six-Feet seam hit severe geological difficulties and during the first six months of 1986 the pit lost £7 million or a loss of £67 per ton produced.

Cwm Colliery, with the exception of anthracite, produced coals that covered the whole spectrum of the types of coals in the South Wales Coalfield; coking, gas, house, steam and manufacturing. The last coalfaces to have worked at this mine were the; 482, 485 and 484.

The No.3 Rhondda seam was abandoned in1945. The Upper-Four-Feet seam was abandoned in October 1958, the No.2 Rhondda seam was abandoned in December 1960, the Two-Feet-Nine seam in January 1964, the Lower-Four-Feet in February 1920, the Yard seam in March 1980, and finally on closure the Five-Feet, Upper-Nine-Feet, Six-Feet, Lower-Nine-Feet and Bute seams were abandoned.

The Coedely section of the mine was closed in April 1985 and the Cwm section on November 28th 1986.

Some Output and Manpower Statistics.

- 1907: Manpower: 188.

- 1908: Manpower: 231.

- 1909: Manpower: 235.

- 1910: Manpower: 694.

- 1911: Manpower: 470.

- 1912: Manpower: 1,253

- 1913: Manpower 1,003.

- 1915: Manpower: 1,429.

- 1916: Manpower: 1,275.

- 1918: Manpower: 1,450.

- 1919: Manpower: 1,309.

- 1921: Manpower 1,322.

- 1923: Manpower: 1,524.

- 1924: Manpower: 1,522.

- 1926: Manpower: 650.

- 1927: Manpower: 897.

- 1928: Manpower: 758.

- 1929: Manpower: 1,041.

- 1930: Manpower: 1,109. Output: 300,000 tons.

- 1933: Manpower: 781.

- 1934: Manpower: 833. Output: 250,000 tons.

- 1937: Manpower: 1,080. Output: 300,000 tons.

- 1938: Manpower: 1,106.

- 1940: Manpower: 1,080. Output: 300,000 tons.

- 1942: Manpower: 1,188.

- 1943: Manpower: 1,154.

- 1944: Manpower: 1,141.

- 1947: Manpower: 1,136.

- 1948: Manpower: 1,100. Output: 330,000 tons.

- 1949: Manpower: 760. Output: 298,000 tons.

- 1950: Manpower: 1,149.

- 1954: Manpower: 1,346. Output: 263,974 tons.

- 1955: Manpower: 1,303. Output: 256,187 tons.

- 1956: Manpower: 1,381. Output: 298,606 tons.

- 1957: Manpower: 1,466. Output: 298,871 tons.

- 1958: Manpower: 1,457. Output: 270,291 tons.

- 1960: Manpower: 1,470. Output: 324,794 tons.

- 1961: Manpower: 1,463. Output: 300,275 tons.

- 1962: Manpower: 1,703.

- 1969: Manpower: 2,134.

- 1970: Manpower: 1,926.

- 1971: Manpower: 1,854.

- 1972: Manpower: 1,783.

- 1974: Manpower: 1,580. Output: 515,000 tons.

- 1976: Manpower: 1,774.

- 1978: Manpower: 1,565. Output: 405,000 tons.

- 1979: Manpower: 1,358. Output: 473,000 tons.

- 1980: Manpower: 1,342. Output: 472,727 tons.

- 1981: Manpower: 1,166.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page