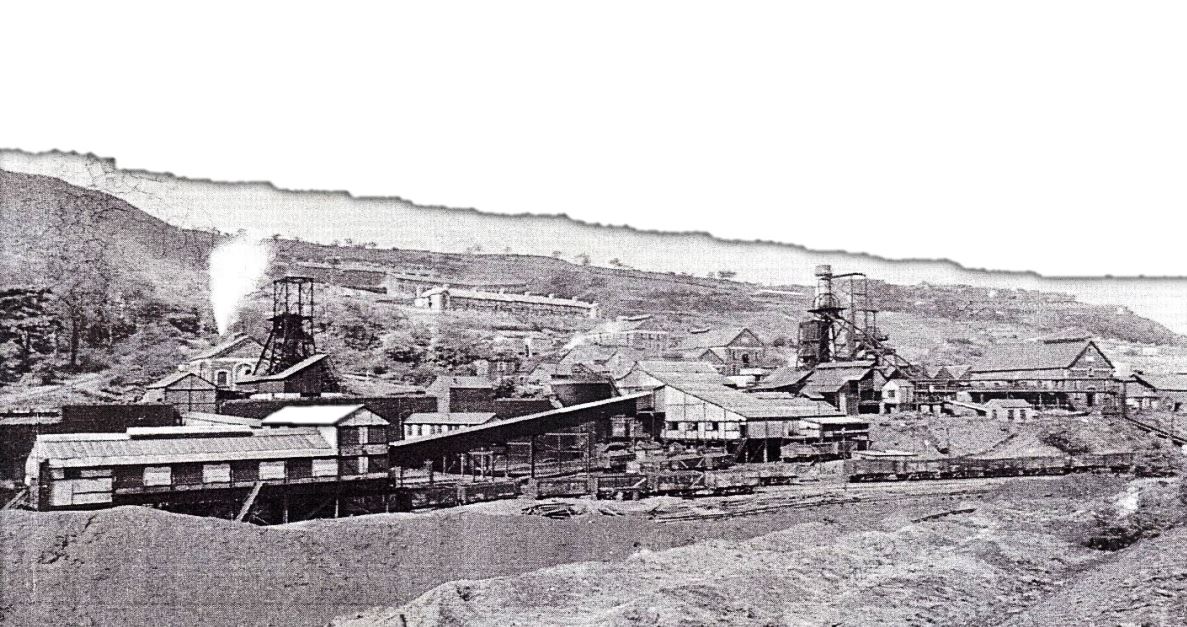

PENRHIWCEIBER (PENRIKYBER) COLLIERY

PENRHIWCEIBER (PENRIKYBER) COLLIERY

Penrhiwceiber, Cynon Valley (06129707)

By the 1870s the northern stretches of this valley had become saturated with collieries with Powell Duffryn dominating the Aberdare area, and John Nixon controlling the Mountain Ash area. To the south of Mountain Ash the area remained virgin, the seams were thought to be too deep and the geology was believed to have been too difficult for mining.

In 1872 a partnership of Messrs. William Cory, Yeo, and John Glassbrook leased the mineral rights in this area, formed the Penrikyber Navigation Coal Company Limited, and started to sink the Penrikyber Colliery roughly in the centre of the coal basin. They immediately encountered problems with excessive water during the sinking and it took six long years before the colliery was ready for production and a cost of £130,000. Three shafts were sunk; the Nos.1 and 2 Pits to the steam coal seams of the Lower and Middle Coal Measures to a depth of 527 yards, they measured 16 feet 6 inches in diameter. For the No.2 Pit, another steam engine was built by Thornwall & Warren and installed in 1901 and the wooden headgear was replaced by a steel one. The No.3 Pit was sunk to the No.3 Rhondda seam of the Upper Coal Measures to a depth of 183 yards. This seam was worked at a thickness of 34 inches although it was later found to actually be the No.1 Rhondda Rider seam. Steam was piped down the pit to supply two pumping engines on the pit bottom. Both engines had the capacity to raise 31,500 gallons of water per hour. It was bounded to the north by Nixon’s Navigation, to the south and east by the Ocean Coal Company and to the west by Ferndale’s.

The Western Mail reported on Thursday, February 11th 1886:

EXAMINATION BY WORKMEN OF PENRIKYBER COLLIERY

On Tuesday and Wednesday, the 26th and 27th of January, 1886, we started at the downcast shaft. We went on the main west return, then down the southwest dip to David Smith’s district. We examined the old works and new, every road and face, and found it all free from gas.

We went up through the straight dip to the branch, Edward Evans’s district. We examined this again, every road and face, and found it all perfectly free from gas.

From here we went up through the main east return to the upcast shaft, from there to the downcast shaft, and from there to the six-feet seam, John Evans’s district. We examined this again, like the former, and found it, like the others, perfectly free from gas.

From here we went through the hard heading, up the old east incline, and through all the old works up to the top of Noah Edwards’s heading, and down through it to old works, examining very carefully, and finding them all free from gas; and if any person doubts us, he is at perfect liberty to see for himself.

We went from here through the east return to the upcast shaft, and from there through the stables and the engine house by the downcast shaft; then up through No.1 north-west return, from there to No.1 north-west district, John Davies’ fireman. We examined this again, old works and new, and found it all free from gas, from here we went down Sidney Hillman’s old heading to Morgan Morgan’s district, No.2 north-west, we examined this very carefully again, roads and faces, and found it free from gas, except, a small blower in Phillip Noakes stall, in the clod in a hole about 2ft., square.

From here we went to Rees Davies’s district Main West, and as we began to examine this district, we found a small blower on John Ledwicks’s road, in a break at the top.

We also found another small blower in Edward Thomas’s stall, turning off John Evans’s heading, on top of the coal where the clod had fallen we went on searching more carefully if that could be, but after searching as carefully as we could through the other part of the district, we found it free from gas, with the exceptions named.

We went from here through the main west return, and up through No.2 north-west return, and then back to the upcast shaft. And we, as examiners, think that great credit is due to the officials of this colliery for keeping such large works in so good a condition.

Signed: William Davies, Jenkin Matthews, Examiners.

The Liverpool Mercury of Thursday, May 29th, 1890, reported:

The prospectus of the Penrikyber Navigation Colliery Company, Limited, has been issued, the capital being £350,000, in shares of £10 each. This company is formed for the purpose of acquiring, working, and developing the Penrikyber Navigation Colliery, situate in the Aberdare Valley, in the county of Glamorgan, together with the business carried on in connection therewith. The Penrikyber property is…adjoining that of Messrs. Nixon and Company, which firm has been working the celebrated four-feet seam for the last 20 years.

The seams at the Penrikyber Colliery are the same (says the prospectus) as those worked at Nixon’s Navigation Colliery, and the coal is known as being of the highest quality of steam coal in South Wales. The taking comprises of coal and other minerals underlying a total area of about 1650 acres, the whole of which is held on leases for long unexpired terms, and at favourable rents and royalties. The colliery is connected to the Taff Vale Railway by commodious sidings, upon which there are suitable screens, weigh-houses, &c., and in direct communication with the docks at Cardiff, Barry, Penarth and Newport.

In 1884 the manager was Llewellyn Llewellyn and in 1896 this colliery employed 1,252 men underground and 201 men on the surface with the manager being William James. In May 1908 this pit had a complete overhaul, with the No.2 Upcast shaft deepened to 670 yards and fitted with double deck cages each deck carrying two trams, enabling a lift of five and a half tons per wind. New screens were installed that consisted of two revolving tipplers, screening belts and separate conveyors for the rubbish. The No.1 shaft replaced its two deck cages with three deck cages, with electric lifts being installed on the pit bottom to enable loading and unloading to be at the same time on all decks. It was intended to wind only on the dayshift in this pit.

On the 30th of October 1909, a fire broke out about one hundred from the pit bottom causing all the men to be evacuated, most of the men at the coalface were affected by fumes and six were seriously affected. The local fire brigade put out the fire that evening. In 1908 the manager was E.L. Hann and in 1916/19 it was T. Phillips. It was served by the Taff Vale Railway with this colliery having a sidings capacity of, 475 full wagons, 406 empty wagons and 136 other types of wagon. In 1903 a Walker type ventilating fan was installed which was 28 feet in diameter.

In 1913 the colliery employed 1,944 men, with sales of Penrikyber’s coal being handled by the Cory Brothers and Company who advertised:

Cory’s Merthyr Steam Coal and Penrikyber Navigation Steam Coal

Cory Brothers & Co., Ltd., supply all the principal Lines of Steamers and are Contractors to the Governments of Great Britain, Germany, France, Italy, Greece, Austria, Brazil, &c..

Penrikyber coal was also on the Admiralty’s list for supply to the British Navy.

In 1915 the publication ‘South Wales Coal and Iron Companies’ from the Business Statistics Company stated that:

With the probability of an increased output, the installation of modern machinery for greater efficiency and economy, the opening out of the No.3 Rhondda seam, and the regularity with which the Colliery is kept working, there is every prospect that the results will prove even more satisfactory to all who are interested in the Company.

Penrikyber Colliery was valued at £337,211 with the profits for the Penrikyber Navigation Colliery Co, Ltd, from 1899 to 1914 being:

1899 – £22,938

1900 – £83,828

1901 – £46,260

1902 – £21,381

1903 – £10,334

1904 – £11,128

1905 – £13,587

1906 – £18,625

1907 – £52,570

1908 – £69,252

1909 – £33,780

1910 – £34,813

1911 – £48,758

1912 – £50,671

1913 – £51,785

1914 – £56,773

The board of directors was; John Glassbrook, Chairman, F.C. Yeo, Sir Clifford J. Cory, David M. Glassbrook and R.W. Cory. In 1930 the manager was still Thomas E Phillips. This Company was a member of the Monmouthshire and South Wales Coal Owners Association. In 1934 the directors of the company were; F. Cory Yeo, Sir Clifford J. Cory, D.M. Glassbrook, R.W. Cory and J.H.L. Glassbrook. The company secretary was Howell Howells.

In 1935 the pit was working the Four-Feet, Six-Feet, Nine-Feet, Seven-Feet, Yard and No.3 Rhondda seams. In 1938 the manager was R.V. Phillips and in 1945 it was T. Tipper.

In 1943 the Penrikyber Company was purchased by Powell Duffryn and immediately the workmen felt the realities of working for this giant combine. Except for the non-unionism disputes that swept the Coalfield there had been no major disputes at Penrikyber for 35 years, but then Powell Duffryn altered the system of paying the colliers from the tonnage system to the yardage system which forced 25 colliers to below the minimum wage. On the 20th of August 1943 the pit went out on strike, with three other pits in the Valley coming out with them. Powell Duffryn refused to budge so the Government’s Regional Coal Controller was brought in and ruled in the men’s favour. At that time the colliery employed 1,062 men working underground in the Four-Feet, Six-Feet, Seven-Feet and No.3 Rhondda seams and 237 men working at the surface of the mine. The manager was T. Tipper.

In October 1944 nine men were taken to court for not working diligently, they had been producing between four and five tons per shift, whereas the company claimed it should have been seven tons per shift. There were found guilty and ordered to pay the company £89. 12s 6d and costs of £8. 6s. 6d.

On Nationalisation in 1947, Penrikyber Colliery was placed in the National Coal Board’s, South Western Division’s, No.4 (Aberdare) Area, Group No.3, and at that time employed 246 men on the surface and 1,146 men underground working the Six-Feet, Nine-Feet, Gellideg and No.3 Rhondda seams. The colliery had its own coal preparation plant (washery). The manager was T. J. Davies who was still there in 1949.

Penrikyber had by now exhausted most of its reserves and began to exploit the coal left when the old Cwmcynon Colliery closed. The No.3 Pit was closed in December 1949, and by 1954 the colliery employed 120 men on the surface and 965 men underground working the Five-Feet, Nine-Feet and Gellideg seams. The manager was now G. Griffiths.

In 1957 the steam winders at Penrikyber Colliery were converted to electricity. This meant building new winding engine houses on the opposite side of the winding headgear to the old ones, and moving the iron supports from the one side to the other side of the headgear. The winding capacity was 48 men or 5 tonnes of materials per wind.

In 1955 out of a total colliery workforce of 1,089 men, 555 of them worked at this colliery’s coalfaces, in 1956 this coalface figure was 580 men, in 1957 there were 606 men working at the coalfaces and in 1958 there were 539 men working at the coalfaces.

In 1958 the colliery employed 60 contractors from the firm Cementation to work on new underground drivages. This project was completed in 1964 at a cost of £1 million and streamlined underground transport systems.

In 1964 out of an average weekly production of 7,000 tons, 4,800 tons was saleable coal. In 1969/75 the manager was R.M. Young while in 1976/80+ it was K. George.

The dramatic variations in the stance of the NUM Lodge can be illustrated by two disputes of the early 1970s; in the unofficial area strike of 1970 the Lodge became very unpopular in the Coalfield by urging a return to work, but in the 1972 National Strike went to the other extreme by stopping the safety men working at the colliery against the instructions of the Union.

In 1978 this colliery was working in an area of four square miles with three coalfaces giving an output per manshift of 4.4 tonnes at the coalface and 1.2 tonnes overall for the colliery. There was more than ten miles of roadways in use including three miles of high-speed conveyors taking the coal to the pit bottom. The main markets for its coal were the nearby Phurnacite Plant and blends for other markets.

This pit which was also linked to Deep Duffryn, Nixon’s Navigation and Cwmcynon had to have a dam built in 1980 between the No.2 shaft and the Navigation shaft in the Gellideg seam level to stop the flow of water from the Deep Duffryn old workings.

In 1981 the colliery worked the Seven-Feet seam at a section of between 133cm and 155cm and the Five-Feet/Gellideg seam at a section of 150cm. Coalface length varied from between 165 metres and 210 metres with coal cutting by ranging drum shearers and coalface roof supports of the self-advancing types. Expected output per manshift on the coalfaces was 5.03 tonnes, and overall for the colliery 1.35 tonnes. The saleable yield of coal was 70% of the total production. In the Seven-Feet seam the B41 coalface was 165 metres long and 1.33 metres thick and had a single shift advance of one metre, or 1,8 metres for double shift working. In February 1981 its life expectancy was 870 metres with a daily output of 494 tonnes. The B42 was the same length and thickness as the B42 and had a life expectancy of 850 metres. The B19 was 209 metres long and 1.4 metres thick and had a daily expected advance of 0.91 metres on a double shift which gave a daily tonnage of 914. This coalface was expected to close in July 1981 and its equipment transferred to the B20. This coalface was 201 metres long and 127 metres thick.

It was expected to advance 0.91 metres on single shift giving a daily output of 707 tonnes. It was expected to start in October 1981 and had a life of 700 metres. In the Five-Feet/Gellideg seam the D31 coalface was 167 metres long and 1.55 metres thick with a daily advance of one metre this gave a daily output of 265 tonnes. This face was closed in April 1981 and replaced by the D32 in July 1981. This face was 183 metres long and 1.5 metres thick. It advanced 1.8 metres on double shift. It had a life expectancy of 400 metres. The D33 was 200 metres long and 1.5 metres thick and advanced 1,8 metres on double shift. It had a life of 560 metres. Manpower deployment was; coalface 160, development 65, elsewhere below ground 249, surface 165. In 1983 this colliery was losing £20.50 on every tonne of coal that it produced.

Following the 1984/85 miner’s strike, the colliery only obtained 55% of the expected output after a month, and pressure by British Coal for closure started almost immediately with 123 men volunteering for redundancy. This caused an uproar with the NUM Lodge who claimed that the men were interviewed without the union’s knowledge and that with their departure the pit could not operate regularly. By June 1985, 50 men over the age of 57 years had been made redundant and 80 others were lined up for redundancy.

In 1986 British Coal stated that due to poor performances at Penrikyber Colliery they were allocating its reserves to Lady Windsor/Abercynon Colliery and Penrikyber would close. Despite the men’s initial decision to go through the Review Procedure for Colliery Closures, they reversed this decision halfway through the procedure and the pit closed.

This colliery’s coals were generally classed as type 201B Dry Steam Coal, low volatile, usually non-caking with a low ash and sulphur content to the west of the shafts and 202 low volume coking steam coals, to the east of the shafts. They were used for steam-raising in boilers for ships, locomotives, power stations etc.

Some of the early fatalities at the colliery:

- 19/3/1875, Thomas Hicks, aged 29, sinker, fell down shaft.

- 2/5/1875, John Evans, aged 38, sinker, fell down pit.

- 5/10/1876, D. Evans, aged 28, sinker, fell down shaft.

- 30/10/1880, Morris Williams, aged 21, haulier, run over by trams.

- 1/9/1881, John Evans, aged 30, collier, fall of roof.

- 9/6/1882, John Jenkins, aged 13, door boy, run over by trams.

- 13/2/1883, Roger Evans, aged 29, haulier, fall of roof.

- 2/3/1883, John Jones, aged 30, shackler, struck by haulage rope.

- 9/5/1883, Robert Williams, aged 18, shackler, run over by trams.

- 10/2/1887, James Palmer, aged 14, collier, fall of roof.

- 3/3/1887, David Thomas, aged 23, collier, fall of roof.

- 27/7/1887, William Davis, aged 18, door boy, run over by trams.

- 10/9/1887, Llewellyn Harris, aged 15, door boy, crushed by trams.

- 18/10/1887, Morgan Davies, aged 28, ripper, run over by trams.

- 21/2/1888, David Harries, aged 16, collier, fall of roof.

- 12/6/1888, William Jones, aged 24, labourer, fall of roof.

- 30/6/1888, David Price, aged 33, rider, run over by trams.

- 12/10/1888, David Thomas, aged 12, door boy, run over by trams.

- 13/11/1888, John Evans, aged 43, collier, fall of roof.

- 2/3/1889, Dennis Hennesy, aged 24, rider, crushed by trams.

- 13/5/1889, John E. Howells, aged 13, door boy, crushed by trams.

- 14/8/1889, Evan Davies, aged 19, collier, fall of roof.

- 16/8/1889, Samuel Jenkins, aged 39, pitman, fall of roof.

- 4/11/1889, David Jones, aged 21, labourer, fall of roof.

- 30/8/1890, Henry Bryant, aged 30, ripper, run over by tram.

- 4/10/1890, Felix Bush, aged 19, collier, fall of roof.

- 24/11/1891, Edgar Street, aged 20, collier, fall of roof.

- 1/4/1892, Walter Mould, aged 29, labourer, fall of roof.

- 7/7/1892, Samuel Jehu, aged 21, collier, fall of roof.

- 18/2/1893, William Miles, aged 28, haulier, crushed by trams.

- 28/11/1893, David Lloyd, aged 52, repairer, fall of roof.

- 9/2/1895, Robert R. Jones, aged 22, rider, run over by trams.

- 4/4/1895, Richard Thomas, aged 37, ripper, fall of roof.

- 17/4/1895, David Davies, aged 55, fireman, crushed by trams.

- 31/7/1895, Charles Stidder, aged 29, ripper, fall of roof.

- 21/9/1895, George Harris, aged 18, rider, run over by trams.

- 8/1/1897, Charles Allen, aged 25, collier boy, fall of roof.

- 10/3/1897, David Jones, aged 45, hard heading man, shotfiring incident.

- 18/10/1899, Charles Field, aged 13, collier boy, fall of roof.

- 3/5/1910, William Reynolds, aged 36, platelayer, run over by trams.

- 20/11/1911, Charles Jones, aged 31, haulier, fall of roof.

- 23/8/1912, John Hughes, aged 48, ripper, crushed by trams.

- 7/11/1912, Edward Evans, aged 39, shifter, crushed by trams.

- 20/11/1912, Thomas Jones. Aged 69, Ashman, fell down a lift.

- 16/12/1912, Francis Hamer, aged 29, haulier, kicked by a horse.

- 5/3/1913, Dennis Buckley, aged 32, timberman, fall of roof.

- 2/4/1913, Frank Thorne, aged 22, shifter, fall of roof.

- 31/5/1913, James Jones, aged 14, collier boy, fall of roof.

- 11/7/1913, Ivor Griffiths, aged 26, collier, crushed by a post.

- 2/2/1914, Bennett G. Barber, aged 52, Ashman, broke his neck.

- 19/2/1914, Frederick Coombes, aged 47, roadman, run over by trams.

- 7/4/1914, William Sadler, aged 24, shifter, fall of roof.

- 8/5/1914, Cleveland Jones, aged 25, cutterman, fall of roof.

- 10/12/1914, Evan Howells, aged 38, collier, fall of roof.

- 5/1/1925, Alfred Collins, aged 37, collier, crushed by tram.

- 24/6/1927, Edward C. Phillips, aged 28, collier, fall of roof.

- 19/7/1927, Walter Lock, aged 34, collier, fall of roof.

- 1/9/1928, John Duncan, aged 56, foreman smith, fell down pit.

Some Statistics:

- 1887: Output: 397,753 tons.

- 1889: Output: 349,006 tons

- 1894: Output: 370,494 tons

- 1896: Manpower: 1,453.

- 1899: Manpower: 1,175

- 1900: Manpower: 1,325

- 1901: Manpower: 1,552

- 1902: Manpower: 1,552

- 1903: Manpower: 1,586

- 1905: Manpower: 1,777

- 1907: Manpower: 1,668

- 1909: Manpower: 1,787

- 1910: Manpower: 1,732

- 1911: Manpower: 1,837

- 1912: Manpower: 1,945

- 1913: Manpower: 1,944.

- 1915: Manpower: 1,995.

- 1916: Manpower: 1,689.

- 1919: Manpower: 1,580.

- 1920: Manpower: 1,580

- 1922: Manpower: 1,980

- 1923: Manpower: 1,983. Output: 450,000 tons.

- 1924: Manpower: 1,980

- 1925: Manpower: 2,175

- 1926: Manpower: 2,307

- 1927: Manpower: 2,080.

- 1928: Manpower: 2,147

- 1929: Manpower: 2,242

- 1930: Manpower: 1,868. Output: 550,000 tons.

- 1932: Manpower: 1,800

- 1933: Manpower: 1,750. Output: 550,000 tons.

- 1934: Manpower: 1,570

- 1936: Manpower: 1,450. Output: 350,000 tons.

- 1937: Manpower: 1,524

- 1938: Manpower: 1,556

- 1940: Manpower: 1,430. Output: 400,000 tons.

- 1944: Manpower: 1,195.

- 1945: Manpower: 1,296

- 1947: Manpower: 1,392. Output: 158,100 tons.

- 1948: Manpower: 1,369. Output: 270,000 tons.

- 1949: Manpower: 1,403. Output: 350,000 tons.

- 1950: Manpower: 946. Output: 253,400 tons.

- 1952: Manpower: 966. Output: 311,500 tons.

- 1953: Manpower: 1,056. Output: 340,100 tons.

- 1954: Manpower: 1,056. Output: 336,200 tons.

- 1955: Manpower: 1,089. Output: 293,481 tons.

- 1956: Manpower: 1,144. Output: 283,651 tons.

- 1957: Manpower: 1,194. Output: 285,665 tons.

- 1958: Manpower: 1,140. Output: 241,459 tons.

- 1961: Manpower: 1,090. Output: 203,542 tons.

- 1962: Manpower: 1,057.

- 1969: Manpower: 939.

- 1970: Manpower: 911.

- 1971: Manpower: 855.

- 1972: Manpower: 855.

- 1974: Manpower: 820 Output: 250,000 tons

- 1978: Manpower: 804. Output: 176,324 tons.

- 1979: Manpower: 754. Output: 217,000 tons.

- 1980: Manpower: 743. Output: 217,055 tons.

- 1981: Manpower: 606.

- 1982: Manpower: 669.

- 1984: Manpower: 649.

- 1985: Manpower: 661.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page