Wheldale Colliery

Copyright © Derek Dye and licensed for reuse under this Creative Commons Licence

In 1868 two shafts, both 13 feet (4m) diameter, were sunk to the Beeston coal seam at a depth of 564 yards (515m); coal production started in 1870.

In 1899 the Wheldale coal company and Fryston coal company amalgamated. In 1919 Wheldale coal company amalgamated with Allerton Bywater colliery to form Airedale Collieries Ltd.

As there was no coal washing plant at Wheldale, a mineral line was laid in the 1930s to Fryston colliery, and coal that required washing was sent to there.

- A couple of years after nationalisation in 1947, Wheldale colliery benefited from some major improvements:

- An electricity supply was installed.

- The winders were fitted with electric motors.

- New double decked cages in the upcast shaft (men & materials)

- Two 6 ton skips in the downcast shaft (coal)

- Conveyor belting.

- Diesel locomotive haulage for men & materials, although pit ponies were still in use up until 1972.

Coal production at the colliery reached around 400,000 tons per year and was supplied to both Ferrybridge Power Station and Glasshoughton Coking plant.

In 1891 an underground fire on the engine plane caused the deaths of 5 colliers; the cause of the fire was unknown. The full report can be found here.

Coal seams intersected by the shafts

| Warren House | 600 ft | (183m) | |

| Haigh Moor | 846 ft | (258m) | |

| Flockton Thick | 1135 ft | (346m) | |

| Middleton Little | 1312 ft | (400m) | |

| Silkstone | 1430 ft | (436m) | |

| Beeston | 1692 ft | (516m) |

When Fryston colliery closed in 1985, a barrel washer had to be set up to clean coal at Wheldale, but this was short lived as Wheldale colliery itself closed in October 1987.

After closure the site was then cleared, but the shafts were not filled. Methane gas from the old workings is used to generate around 10MW of electricity, enough to power around 8000 homes.

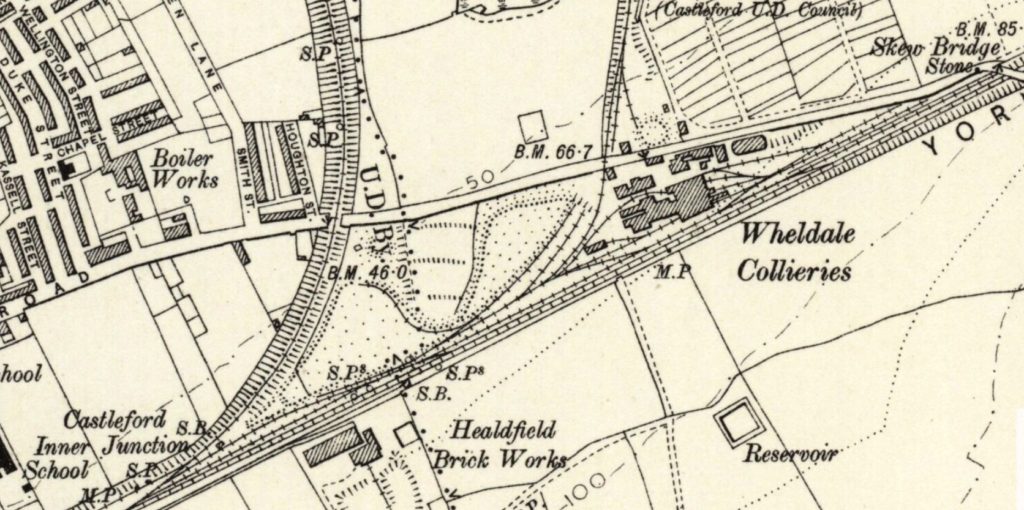

OS Map, Yorkshire CCXXXIV.NE 1905

Reproduced by permission of the National Library of Scotland