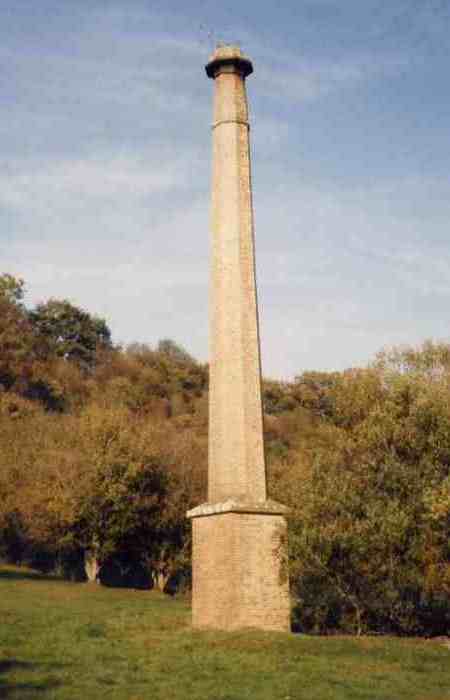

Chimney at East Van Mine

Copyright © Chris Andrews and licensed for reuse under this Creative Commons Licence

Two miles NNW of Llanidloes, the vein at Van runs WSW to ENE in Silurian and Ordovician grits, mudstones and shales. It was very wide, making it difficult to work. The first ore from Van was sold in 1866, but the vein had been worked to the west at Bryntail Mine from an early date. The 110 metres of ore-bearing ground at the adit increased to 365 metres at the 90 fathom level, but it was too poor to work by the 120 fathom level. Unlike most lead mines, Van was troubled by methane which caused small explosions and led to the use of safety lamps.

The Van Mining Company, floated in 1869, was headed by George Batters. He was a major shareholder in West Chiverton lead mine in Cornwall, and at Darren in Cardiganshire. The company secretary, W.J. Lavington was involved in mines in Cornwall, Wales and Yorkshire.

Until 1875 the Engine Shaft workings were drained using rods from the Mary Emma waterwheel on the dressing floor. The vein dipped steeply to the south, so a new vertical shaft, Seaham’s, was sunk well to the south of its outcrop in order to cut it at a depth of 120 fathoms. Crosscuts were driven from the shaft to the vein every 15 fathoms and stopes developed from them.

The ore was distributed throughout the vein, however, so stoping left vast voids which made the ground unstable. To stop this rock, mined from the vein walls, was used for support. Waste was also dropped down special chutes and used to backfill voids as was done at Frongoch. The annual output of lead ore went over 1000 tons in 1868 and averaged 4265 tons until 1884. Zinc blende was also produced.

A road was built to the nearest railway at Llandiloes, but carting large amounts over it caused problems and was expensive. In 1871, therefore, a standard gauge railway was built to link the mine to the main line at Caersws. It carried materials to the mine and took ore to be smelted.

At the western end of the mine, work began on sinking Edwards Shaft in 1869. It eventually reached the 150 fathom level. In 1870 Seaham’s Shaft was fitted with a steam winding engine and a single cage, which was counterbalanced by a weighted waggon running up and down an incline on the hillside. A compressed air plant was built in 1883 and machine drilling began. This cut the cost of driving levels and speeded up their advance.

Despite lead prices falling in the 1870s, the mine made profits. In 1884, however, it was selling dressed lead ore at a loss. The mine stood for much of that year, and the company was put into liquidation. It’s successor had the same name and many of the same directors. It began work in 1885 and was the first in the usual series of companies trying to emulate old successes.

Low lead prices forced the mine’s closure in December 1890, but pumping was maintained. Yet another reincarnation of the old Van Mining Company soon came on the scene, this time with a capital of £60,000. It failed to raise enough capital, however, and folded the following year.

Next came Edward Woods & Co. who, from 1892, treated dump material as well as working parts of the mine. It gave up in 1901 to be followed by Van Mines Ltd in 1902. It also worked the mine and made some very modest profits before closure in January 1908.

In November 1908 the Llanidloes Mining & Machinery Co. Ltd reopened the mine. Soon there was optimistic talk of the New Lode, which was giving off lots of methane and black water. This, was said to be like the time when the old vein was first cut into. The mine was short of labour, and when the company imposed new working conditions in order to comply with recent legislation, the men objected by going on strike in July 1909.

By 1916 the men were working pillars and development work stopped for a month. The end came before July, when the Welsh Van Mining Co. Ltd was registered and began working the mine. Electrification, begun by its predecessor, was expanded, and more compressed-air drills were installed. In 1922, faced with low prices and lacking funds, the company closed the mine. It was worked for barytes during the second World War, but only above water level.

- Chapman, N.A. The Van Mine (British Mining No.81, 2007)

- James, D.M.D. “Lode geometry in the Plynlimon and Van Domes, Central Wales, UK: the relative importance of strike swing and relay linkage”, British Mining No.80, pp.60-87 (2006)

- James, D.M.D. “The East Van Failure, Powys, Wales: A new look at the geology and the archival record”, British Mining No.86, pp.109-121 (2008)