Bedwas, Rhymney Valley (ST 1780 8931)

Bedwas, Rhymney Valley (ST 1780 8931)

The ‘Colliery Guardian’ dated the 21st of May 1909 reported that “Bedwas Colliery was commenced a few days ago…30/40 men having started work of levelling the sidings from the Brecon and Merthyr Railway and opening out foundations for the engine houses etc.”

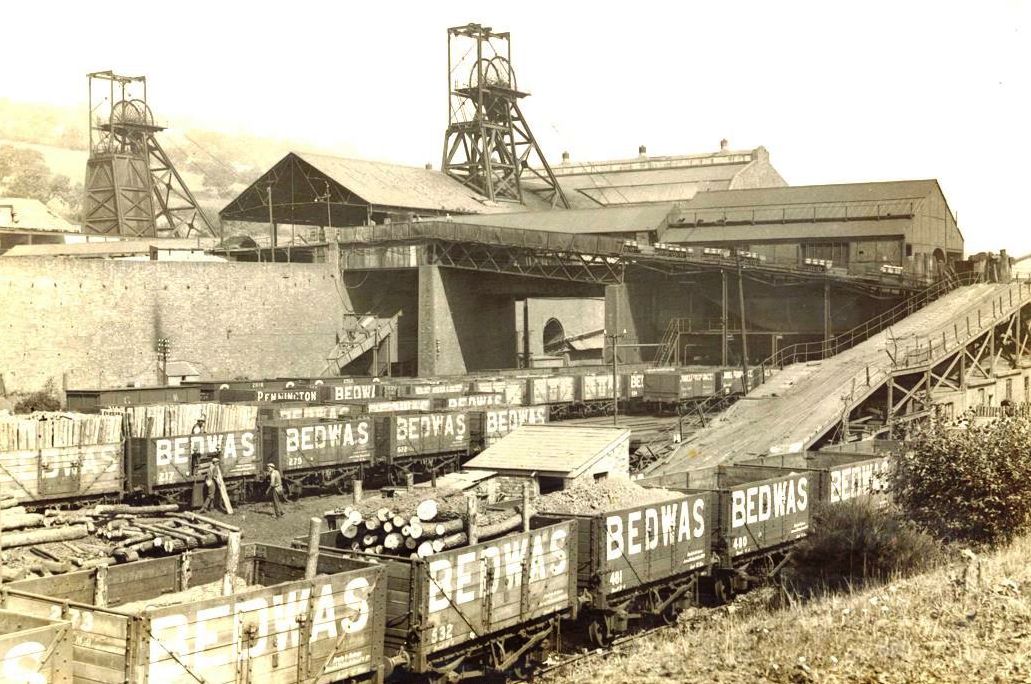

The Times 25th of May 1910 reported; ”On May 18, 1909, Mr. E. M. Hann, the manager of the collieries of the Powell-Duffryn Company, took in hand on behalf of a new company the sinking of a new colliery at Bedwas, near Caerphilly, on the southern boundary of the South Wales coalfield. Most of the permanent plant and machinery has now been installed in an exceptionally spacious and well-built engine house, and one shaft has been sunk to a depth of 110 yards, and another top a depth of 60 yards. It is expected that the colliery will give an output of 2,000 tons a day. The two main seams, which it is proposed to work, are the Four Feet and the Black Vein, which will be reached at a depth of about 660 and 700 yards respectively. The taking covers an area of 2,000 acres, and for surface purposes, about 36 acres will be absorbed. Both shafts will have a diameter of 21 feet from top to bottom. The pit-head gears, which reach a height of 70ft., are constructed of broad section H girders and channels…the distance between the centres of the two shafts is 60ft…The main building, in which all the winding and electrical machinery are housed, is 250ft. long, 68ft. wide, and 79ft. high from the basement.”

On the 17th of January 1912, the Times added; “At the new Bedwas Colliery one shaft has been sunk to a depth of 786 yards to a seam of coal 16 yards below the famous Black vein, and it is expected that the other shaft will reach the same depth in the course of the next two months. The colliery has an output capacity of 4,000 tons a day, and it is anticipated that the owners will begin to raise coal within the next six months.”

The two 21 feet diameter shafts, the North and South Pits, were not sunk until the permanent machinery was installed. The sinking of the North Pit started on the 4th of April 1910 and the sinking of the South Pit started on the 27th of May 1910 with the first coal being wound in 1912. The shafts were 2,561 feet deep and sunk to the Five-Feet/Gellideg (Old Coal) seam. The North Pit was the upcast ventilation shaft and had a single deck carriage and rope guides while the South Pit was the downcast ventilation shaft and had double-decked carriages and rigid guides. They were the deepest shafts in the Coalfield up to that time and remained the deepest ever to be sunk in the Rhymney Valley. They were also the only shafts in the Coalfield that cut through all the coal seams from the Mynyddislwyn seam to the Gellideg.

Difficulty with excessive water was met in both shafts, within the North Pit a water feeder at 80 yards depth held up sinking for three days. Another three days sinking was lost due to a feeder at 250 yards depth, while sinking was further halted between the 11th of November and the 8th of December to make a lodge room and pumphouse at a depth of 321 yards where 800 gallons of water per hour was met. At the South Pit at a depth of 87 yards, a feeder stopped sinking between the 30th of June and the 8th of July while further feeders were hit at 102 yards, 200 yards and 296 yards. The Little Rock seam was struck on the 19th of June 1911 at a depth of 540 yards and the Big Rock seam on the 2nd of August at a depth of 602 yards. At the 670 yard level sinking was suspended and a roadway was driven from the South Pit to the North Pit. At 755 yards the Big Vein was struck, the Black Vein was struck on the 10th of February 1912. In all the average speed of sinking the pits was 8.33 yards per week. There were three pumping levels; at 330 yards, 600 yards and pit-bottom handling up to 720,000 gallons of water a day, all of it was used on the colliery premises for the boilers, washery and coking plants.

On the 15th of July 1911, William J. Thomas aged 43 years and Thomas Bagley aged 38 years, and both sinkers died when they fell down the pit.

In the main building around a third of the roof was made out of glass to make the inside as bright as they could, with an electrical overhead crane capable of lifting 26 tons on hand to move heavy machinery around. The steam winding engines were the double tandem combined types fitted with drop valve gear and Robey’s overwind protection. They were made by Robey and Company and both had two 31 inch diameter cylinders which had a 72-inch stroke, the drums were semi-conical in shape and ranged from 14 feet up to 22 feet in diameter. The headgears were 70 feet high to the centre of the sheaves. A double set of air compressors were installed capable of 5,000 cf at 60lbs pressure. The exhaust steam from the winding engines was used to power the electrical generator. A sirocco type fan was installed and gave up to 400,000 cubic feet of air per minute. The boilers used to raise the steam for the winders were situated directly behind the main building. There were 12 Lancashire type boilers measuring 30 feet by 8 foot 6 inches.

At the time of the sinking of Bedwas (1909) most of the best mineral leases had gone, the main virgin area left was near the southern outcrop, with the coal trade still booming sinking’s at Nantgarw and Bedwas went very deep to find the geology of the area very disturbed, with at some places the seams rising almost vertically. The first attempts at coal getting were on the west side of the pit in a 56-inch thick seam. The seam had been opened out to eight workplaces when an outburst of water at a rate of 10,000 gallons per hour caused it to be abandoned.

On the 27th of March 1912 at 11.30 am an explosion of methane gas killed three miners and injured another nine. Those that died were Thomas Wilts aged 24 years, Henry Wilts aged 22 years and John Edmunds aged 36 years, Those injured were:

- Sidney Barnes aged 31 years and a collier.

- Humphrey Davies aged 33 years and a collier.

- Joseph Jones aged 28 years and a timberman.

- J.M. Jordan aged 35 years and the manager.

- Thomas Price aged 45 years and a collier.

- Charles Richards aged 20 years and a collier.

- Alexander Saunders aged 20 years, engine driver.

- David Thomas aged 36 years and a shotsman.

- Tomas Williams aged 40 years and a fitter.

Also seriously injured in that year were;

- 12/4/1912, James Bailey aged 32 and a riveter overbalanced and fell 30 feet.

- 20/5/1912, Henry Dando aged 39 years was injured under a roof fall.

- 4/10/1912, James Nelmes aged 20 years and a collier was injured by a fall.

- 5/10/1912, F.E. Jones aged 25 years and a rider was injured when crushed by trams.

- 13/11/1912, Caleb Boyer aged 21 years, was badly injured when crushed by a tram.

- 18/12/1914, Thomas Evans aged 42 years and William Griffiths aged 41 years died under the same fall of the roof just two of the many who died in this pit.

The manager of the colliery in 1913 was J.W. Jordan, and in 1915/18/19 W. Thomas.

The industrial relations problem started as soon as the colliery was in full swing. On Wednesday, 23rd September 1915, almost 1,000 men came out on strike following a show of cards, they said they would not return until the surface craftsmen joined the South Wales Miners Federation (a ‘show of cards’ was normally carried out by union officials who demanded that the workmen show them their membership cards. This system caused bitter resentment with management and High Court cases followed which stopped the union men from entering the premises for that purpose. It also caused bitter resentment amongst the miners and violent confrontations ended with arrests, fines, and imprisonment.

Due to the difficult geology of the southern outcrop, and the 1921 lock-out, the financial problems of the Navigation Company were such that in 1921, a reconstituted subsidiary of Instones Limited was formed and called Bedwas Navigation Colliery Company (1921) Limited.

In 1934 the pit employed 1,550 men underground and 164 men on the surface, at that time the pit was working the Nine-Feet (Black Vein), Four-Feet (Big Vein), and No.2 Rhondda (Rock) seams producing steam and house coals. The manager in 1923/30 and was D.H. Walters. It was Fred Stacey in 1934 and in 1938 the manager was T. Ashurst. On the 18th of November, 1939 new pithead baths were opened, they had cost £32,470 to construct. The colliery also included a coal preparation plant (washery), coke and by-product plants.

In 1943 it employed 1,510 men working underground in the Black, Lower Black, Big Rock and Meadow Vein seams and 313 men working at the surface of the mine. In 1943/5/9 I.M. Richards was manager.

Along with the Nation’s other coal mines Bedwas was Nationalised in 1947 and came under the control of the National Coal Board’s South Western Division’s No.5 Area, Group No.4. Placing the colliery under the control of the ‘people’ did little to change the industrial relations problems at the pit, the Joint National Negotiating Bodies minutes for the meeting of the 15th of January 1949 show that both the NCB and the NUM condemned a strike at Bedwas where the safety men were withdrawn.

On the 10th of October 1952 at 6.30 pm in a district being opened, there was an explosion at this pit which killed a deputy, Mr. A. Griffiths and severely burned several others.

By 1954 it employed 1,316 men underground and 235 men on the surface working the Big Vein, Meadow Vein (Yard/Seven-Feet), Lower-Nine-Feet and Big Rock seams, the manager was now S. Evans. The coals were then classed as; coking, house, manufacturing and steam.

In 1955 out of a total of 1,506 men employed at this colliery, 630 of them were working at the coalfaces.

In 1956 the revised price list for the three feet thick Lower Black Vein seam was; one shilling and eleven pence per square yard of coal filled by hand and one shilling and eightpence per square yard for coal filled by a machine.

In January 1957 the NUM Lodge at Bedwas decided not to allow Hungarian refugees to work at the pit. A meeting had been unanimous in that decision. They voiced concern over a shortage of housing for local workers and it would be unjust if Hungarians came and ‘jumped the queue.’

In 1958/60 the NCB invested £4 million, and re-organised this colliery, investing in new winding engines of 2,850 h.p. with a capacity to wind forty men or six tonnes of coal per wind, a new pit bottom, electric locomotives underground and a new washery at the surface.

When compulsory retirement at age 65 years was implemented in 1959 there were 51 men over that age working at this pit. In 1961, 408 men were employed on the coalface, with total manpower for the colliery of 1,130 producing 315,051 tons of coal. In 1961 Bedwas Navigation Colliery was still in the No.4 Group of the No.5 Rhymney Area along with Llanbradach and Windsor collieries. Total manpower for this Group was 2,672, while total coal production for the year was 651,225 tons. The Group Manager at that time was N. Walters, and the Area Manager was G. Tomkins. In 1962 this colliery recorded a financial loss of £260,000. In 1969 to 1978 the manager was G. Pritchard. In 1980 it was W. Cecil. In January 1968 this colliery produced 10,000 tons of coal in a week for the first time in 30 years as part of its remarkable recovery. In July 1967 output per man shift was 18 cwts and the colliery was in danger of closing. By January 1968 the OMS was 35 cwts.

On the 17th of May 1974, there was intense heat coming out of the B33 District raising fears of an underground fire or explosion and the pit was evacuated for four days until the area was sealed off.

In 1978 the working area of this mine covered 5 square miles, the output per man shift was 7.5 tonnes on the coalface and 1.7 tonnes overall for the colliery. The NCB estimated coal reserves of 10 to 15 million tonnes.

In 1980 when the NUM Lodge at Britannia Colliery agreed to a manpower reduction at Britannia Colliery part of the agreement was that none of the men would be transferred to Bedwas Colliery, such were the conditions at Bedwas.

In 1981 the pit was working the both the Meadow Vein and Six-Feet seams on the longwall method of coal extraction with coalface length varying from between 139 and 190 metres. Coal cutting was by ranging drum shearers and coalface roof supports were the self-advancing type. Output per man shift on the coalface was 5.41 tonnes and overall 1.4 tonnes. The saleable yield from the coal raised was 60%. Manpower distribution was; coalface 157, development 110, other underground 203, surface 154. The Yard/Seven-Feet seam coalfaces were prefixed by the letter “M” with the M30 coalface advancing on average 1.2 metres per day on single shift coaling giving a daily coal output of 300 tons. This face was expected to close in December 1981. It was to be replaced by the M46 coalface which was to advance at a rate of 1.8 metres a day on a single shift producing 550 tonnes of coal per day. It had a life of 1,000 metres. The M45 coalface was advanced 2 metres per day on double shift producing 400 tonnes of coal until December 1981 when it would drop to single shift working and advance 1.2 metres per day giving 250 tonnes of coal. The Six-Feet seam coalfaces were prefixed by the letter “B” with the B101 advancing 0.8 metres per shift on a single shift due to a geological fault in the tail end. It produced 200 tonnes of coal a day and was expected to close in November 1981 and be replaced by the B102 coalface which was expected to advance 1.3 metres a day on double coaling shifts producing 400 tonnes of coal a day. Its life was expected to be 350 yards.

Following the return to work after the year-long miners’ strike, in March 1985, severe geological conditions had meant the loss of the only two coalfaces at this pit and it would be at least nine months before any coal can be raised. On March 23rd 1985 more than 300 men at Bedwas Colliery rejected the advice of the lodge committee and voted for the closure of the pit. Only 45 men of the 365 men at the meeting voted to continue to fight the closure. Out of a total manpower of 429, 174 underground and 73 surface workers accepted voluntary redundancy, the rest were transferred to other pits. NACODS weren’t very happy with the closure and took it to the High Court claiming that the review procedure hadn’t been carried out. The High Court rejected the application. The NUM Lodge Secretary on closure was C. Harris. This Colliery was closed by the National Coal Board on the 31st of August 1985 with the NCB claiming that it had not recovered from mining problems created by the strike.

Some Statistics:

- 1909: Manpower: 1,177.

- 1911: Manpower: 1,385.

- 1912: Manpower: 508.

- 1913: Manpower: 500.

- 1915/6: Manpower: 1,800.

- 1918: Manpower: 1,263.

- 1919: Manpower: 1,800.

- 1920: Manpower: 1,800.

- 1923: Manpower: 2,565. Output: 500,000 tons.

- 1924: Manpower: 2,652.

- 1927: Manpower: 2,741.

- 1928: Manpower: 2,361.

- 1930: Manpower: 2,550 Output: 650,000 tons.

- 1932: Manpower: 2,500.

- 1933: Manpower: 1,647.

- 1934: Manpower: 1,714. Output: 500,000 tons.

- 1936: Manpower: 1,624.

- 1938: Manpower: 2,040.

- 1939: Manpower: 1,850. Output: 675,000 tons.

- 1940: Manpower: 1,890. Output: 700,000 tons.

- 1943: Manpower: 1,823.

- 1944: Manpower: 1,550. Output: 400,000 tons.

- 1945: Manpower: 1,823.

- 1947: Manpower: 1,775.

- 1948: Manpower: 1,777. Output: 436,948 tons.

- 1949: Manpower: 1,874. Output: 436,948 tons.

- 1950: Manpower: 1,709.

- 1953: Manpower: 1,513. Output: 453,000 tons.

- 1954: Manpower: 1,551. Output: 431,000 tons.

- 1955: Manpower: 1,506. Output: 428,830 tons.

- 1956: Manpower: 1,562. Output: 403,720 tons.

- 1957: Manpower: 1,558. Output: 402,629 tons.

- 1958: Manpower: 1,494. Output: 348,103 tons.

- 1960: Manpower: 1,183. Output: 345,041 tons.

- 1961: Manpower: 1,130. Output: 315,051 tons.

- 1962: Manpower: 1,151.

- 1964: Manpower: 1,182.

- 1967: Manpower: 1,217. Output: 363,718 tons.

- 1968: Manpower: 1,117. Output: 357,696 tons.

- 1969: Manpower: 947. Output: 268,456 tons.

- 1970: Manpower: 877. Output: 234,831 tons.

- 1971: Manpower: 819. Output: 226,449 tons.

- 1972: Manpower: 738. Output: 259,152 tons.

- 1973: Manpower: 629. Output: 174,429 tons.

- 1974: Manpower: 647. Output: 247,738 tons.

- 1975: Manpower: 667. Output: 220,543 tons.

- 1976: Manpower: 693. Output: 237,265 tons.

- 1977: Manpower: 705. Output: 197,162 tons.

- 1978: Manpower: 694. Output: 132,699 tons.

- 1979: Manpower: 703. Output: 140,055 tons.

- 1980: Manpower: 694. Output: 140,056 tons.

- 1981: Manpower: 624

- 1985: Manpower: 615.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page