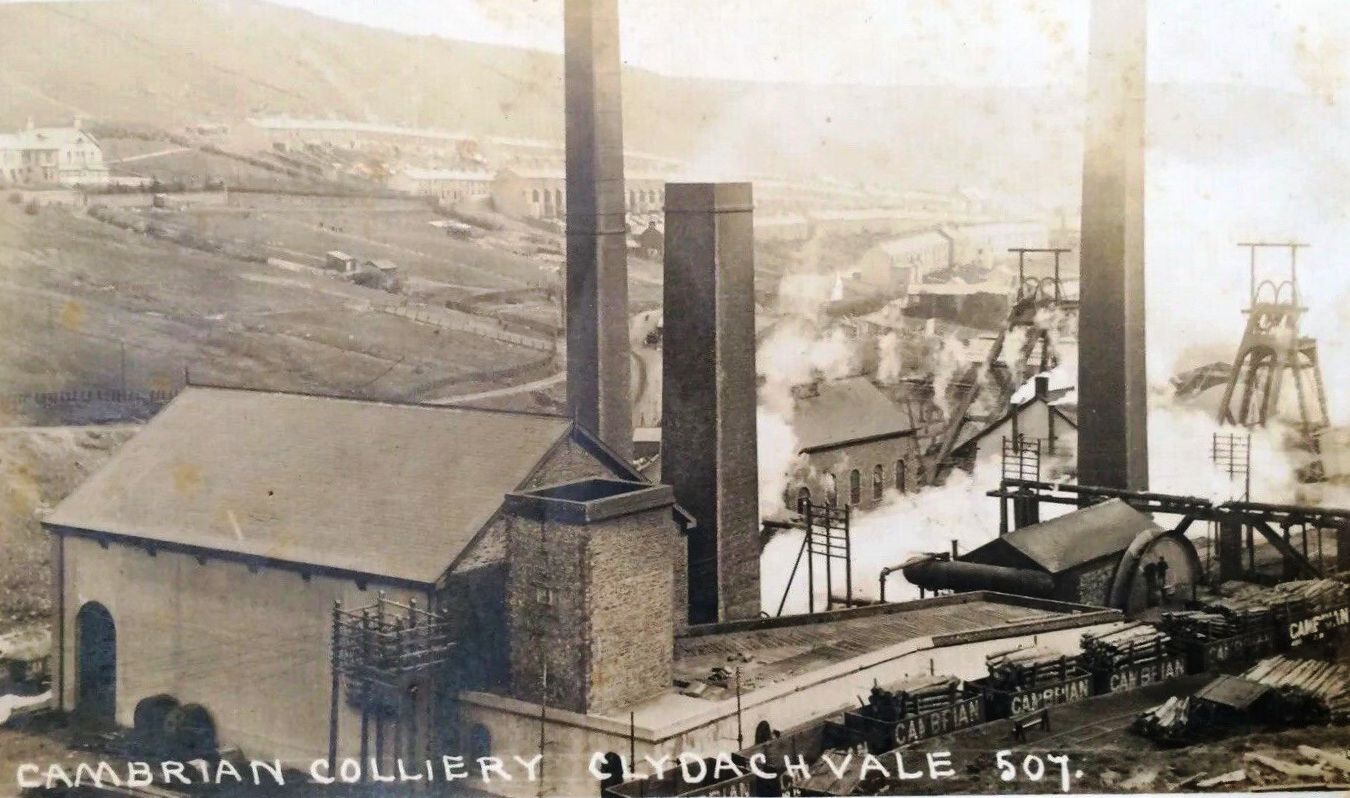

Cambrian Colliery c1912

Clydach Vale, (No.2: SS 9704 9272, No.3: SS 9693 9265, No.4: SS 9703 9270)

Planning for the colliery started in 1870 with a company formed in 1871 by Samuel Thomas and Osborne Riches. They commenced sinking the No.1 Pit in 1872 and struck the Six-Feet seam at a depth of 400 yards in 1874. It was a downcast ventilation shaft 16 feet in diameter.

The steam winding engine for this pit was built by Messrs. Llewellyn & Cubitt of the Rhondda Engineering Works, Pentre, and had two horizontal cylinders 42 inches in diameter with a six-foot stroke. It had cylindrical drums of different sizes, one being 20 feet 6 inches in diameter and the other 15 feet 9 inches in diameter.

The larger drum worked the coal from the Coronation seam and the smaller drum worked the coal from the Six-Feet seam. The steel winding rope was 5½ inches in circumference. The cage was the double-deck type with room for one tram per deck, each tram carrying about 1.75 tons of coal. The putting off of the full trams, and putting on of the empty trams at the surface, and vice-versa at pit bottom was done simultaneously. The pit was built to raise 1,800 tons of coal per shift with the record being 2,450 tons of coal raised in nine hours. Following the success of this pit they extended the mineral lease and sunk two new shafts; The No.2 Pit in 1874/5 to the Lower-Nine-Feet (Red Vein) seam at a depth of 1,314 feet 9”. The steam winding engine was built by Messrs Llewellyn & Cubitt and it had two horizontal cylinders 40 inches in diameter with a six-feet stroke. The two parallel winding drums were cylindrical and were 20 feet in diameter, the winding rope was round and 5.25 inches in circumference. The cages were as the No.1 but with an average capacity of 1,600 tons of coal per day; with the record being 2,730 tons.

On the 9th of June 1891, The Times newspaper reported:

NEW COLLIERY WORKS.-On Saturday, in the presence of the leading merchants and mining engineers of South Wales, Mrs. Thomas formally started the new colliery works of the Cambrian Navigation Colliery Company, of which Mr. D. A. Thomas, M.P., is the managing partner. The works are situated in the centre of the celebrated Rhondda Valley, and comprise a shaft, said to be the largest in the United Kingdom, and a ventilating fan capable of producing half a million cubic feet of air per minute, the largest ever constructed up to the present time. It is estimated that 10,000 persons will be dependent on their subsistence upon the undertaking when it is fully developed.

The No.3 Pit was sunk between May 1889 and June 1891 to just below the Gellideg seam at a depth of 555 yards, it was the upcast ventilation shaft and had a diameter of 21 feet. It was 123 yards from the No.1 Pit. It was sunk and walled at a rate of 4.85 yards per week. The steam winding engine had cylinders of 36-inch diameter and six feet stroke, with a conical drum ranging from 19 feet in diameter down to 16 feet. It was made by Messrs. Thornewill & Warham of Burton on Trent. It had an average capacity of 800 tons of coal per shift.

A water-softening plant had been erected, of the Archbutt-Deeley type, capable of dealing with 18,000 gallons of water per hour.

Power for ventilating, winding, and for some of the haulages underground was provided by twenty Lancashire boilers 30 feet by 8 feet, with pressures varying from 60 to 120 lbs. per square inch, supplied by Messrs. Daniel Adamson and Co., and Messrs. Tinker, Shenton and Co.

The screening plant supplied by Messrs. Head, Wrightson and Co., of Thornaby-on-Tees, is capable of dealing with 5,000 tons per day; there are five large coal-picking bands, two small coal belts, and one stone belt running across the centre of the large coal-belts. Provision had been made in this plant for dealing with four classes of coal — large, small, duff, and nuts. The whole is electrically operated by motors of various horse-powers supplied by The British Westinghouse Co., Manchester, each belt is worked separately. The five large coal belts lead to different weighbridges, all the weighing being done from overhead.

The other surface plant, namely, sawmills, fitting shops, smithies, and chaff-cutting, are driven electrically with power supplied by the South Wales Electric-Power Distribution Co. The power is delivered at the transforming station at 3-phase alternating current, 25 cycles, 11,000 volts, and transformed for surface work to 440 volts, and for underground purposes at 2,200 volts. For underground purposes, a main cable, capable of taking 1,500 H.P., is laid from the distributing station to a sub-station situated in the Red Vein seam, the respective circuits for all the haulages being taken from this station.

On the 19th of May 1893 the company placed the following advertisement in the Colliery Guardian:

For sinking their No.2 Clydach Vale pit to a further depth of 100 yards, more or less, 16 feet in diameter. For Messrs. Thomas, Riches and Company, Bute Docks, Cardiff.

On Monday, 29th of May 1893 the men were informed that notices were given that all work would stop at the end of the month unless the men filled out only clean coal, that they agreed to be fined or dismissed if they didn’t. That 4½ pence be taken off the price of each ton the men produced and that the nightshift work on Saturday and Sunday nights. Failure to agree to these proposals and the pit would be shut and the No.2 pit deepened to the Seven-Feet seam. The men asked for the notices to be withdrawn while negotiations took place but the manager refused to do so, although the men agreed to concessions. D.A. Thomas refused to meet them stating that the directors wanted to sink to the Seven-Feet seam. In December 1894 the company secured a contract for almost 800,000 tons of coal for the Royal Mail steamers out of Southampton. In 1901 there were four steam-driven haulage engines working in the Six-Feet seam with the steam supplied from the surface.

The No.4 Pit was sunk from 1912 to 1914 to the Yard seam which it encountered at a depth of 456 yards. It was 20 feet in diameter and was 26 yards from the No.2 Pit. The original ventilation fan was a 20 feet diameter steam-driven Schiele fan capable of producing 400,000 cubic feet of air per minute. This was later used as a reserve fan for a 35 foot Waddle type fan which also produced 400,000 cubic feet of air per minute.

Four steam-driven haulages (supplied from the surface) were installed in the Six-Feet seam workings. In the Red Vein by 1895, the main hauling engine was a 220-B.H.P. motor, working at 2,000 volts, 25 cycles per second, 180 revolutions per minute, geared 5 1/2 to 1, which deals with half the output of this seam (800 tons per day). All the underground motors were made by The London Electrical Co., supplied and erected by Messrs. D. Selby Bigge and Co., Newcastle-on-Tyne. The west side of the No. 2 Pit is still worked by steam engines. The two main hauling engines are fed by means of an endless-rope electrical engine, 150 H.P., 2,000 volts, 25 cycles per second, 170 revolutions per minute. The 6-foot seam was by then worked by a similar electrical engine to that described in the No. 2 Pit. The Coronation seam is worked by a 24-inch hauling engine, 6-foot drum, main and tail from the surface; there are also several other small steam and electrical engines working in the different parts of the collieries. The management of the collieries is under Mr. Leonard W. Llewelyn. The original system of coalface work was by the Barry or Nottingham systems in which levels were driven off the main heading every 60 yards. The coal was then hand filled into trams which horses would take to the main haulage road where journeys would be made up and taken by haulage rope to the pit bottoms.

The Gellideg seam was called the Lower-Five-Feet seam in this area and was extensively worked at a thickness of 66 inches. The Yard seam was called the Bute and worked at a thickness of 42 inches. The Lower-Nine-Feet seam had a thickness of 33 inches. The Upper-Nine-Feet seam was called the Six-Feet seam at this pit and was worked with a thickness of up to 74 inches interlaced with dirt partings. The Lower-Six-Feet seam was 83 inches in thickness but again had dirt partings. The Two-Feet-Nine seam was worked at a thickness of 66 inches. The Pentre seam was extensively worked at a thickness of 39 inches.

Based on the Nine-Feet seam this colliery’s coals were classed as types 203 and 204 Coking Steam Coals, type 203 was weak to medium caking, while 204 was medium to strong caking, both were low volatile coals with an ash content of around 5% to 9% and low sulphur content of between 0.6% to 1.5%. The main uses were for steam raising, foundry and blast furnace coke and coking blends.

The colliery got off to a prosperous start with between 1890 and 1894 daily output averaging 700 tons, the record output for one shift in the No.2 Pit was 2,534 tons. In 1896 the No.1 Pit was managed by David Roberts and employed 1,170 men underground and 340 on the surface, the No.2 Pit was managed by Edward Hammond and employed 1,318 men underground. This Colliery was served by the Taff Vale Railway and in 1898 had a sidings capacity of; full wagons, 192, empty wagons, 261 in other sidings, and 389, making a grand total of 842 wagons.

Samuel Thomas died in 1879 and Thomas Riches in 1888. Following the death of Samuel, his sons became managing partners, and it was in 1895, that formed a public limited liability company called Cambrian Collieries Limited which had a share capital of £600,000. This company was a member of the Monmouthshire and South Wales Coal Owners Association.

On Friday, 1st January 1898, a fire broke out in the main winding engine house and destroyed the building and two engines at a cost of £8,000. The 500 men underground at the time were brought up the upcast shaft, but all 1,200 men were temporarily thrown out of work. On Saturday, 9thof April 1898, two thousand miners met on the mountainside to be informed by their leaders that the company had decided to hold back the wages that the men were owed due to them walking out without giving notice. They further told the men that the pit would remain closed until the owners decided otherwise. In July 1898, 4,000 men on double coaling shifts were producing 30,000 tons a week.

The Colliery Guardian of the 21st May 1909 reported that on the past Friday, Cambrian raised 5,348 tons of coal in a ten hour shift beating the previous record of 4,100 tons of coal.

In March 1910, a dam at the mouth of the old Blaenclydach level, Clydach Vale, collapsed and the water poured down the valley killing six people; Mrs. Elizabeth Williams, aged 34, and her infant child, of Adam Street, little Gertrude Rees aged four years, of Marion Street, Blodwen Davies, aged nine years, and the daughter of the under-manager of Cambrian, Enid Howell aged six years, of Wern Street, and the infant daughter of a Mr. T.H. Brimble. The deluge was caused by years of water building up in the old workings, followed by days of torrential rain. Several houses, particularly in Adam Street, and the School were damaged.

In 1906, one of the brothers, David Alfred Thomas (later Lord Rhondda) devised a plan to link the Cambrian, Glamorgan, Naval and Britannic Merthyr Companies together to form a combine which eventually could dominate the Coalfield and regulate wages, prices etc. This eventually led to the formation of the Cambrian Combine.

In 1916 the No.2 Pit was managed by T.L. Evans and the No.3 Pit I. Morgan. In 1918 the No.1 Pit was managed by J. Jones, the No.2 Pit by E. Morgan the No.3 Pit by T.W. Evans and the No.4 Pit by F. Athay. In 1923 the managers were; No.1/3, E. Morgan. No.2, T.W. Evans. No.4, F. Athay. In 1927/30 the overall manager was T. Johns. At that time it was working the Coronation, Red, Bute, and Two-Feet-Nine seams.

The intensive mining of the area was now rapidly exhausting the reserves at Cambrian and the first of the pits to close, the No.3 Pit was closed in 1936. In 1943/5 the manager was A.J. Higgs and the No.1 Pit employed 47 men working the Pentre seam, the No.2 Pit employed 402 men working the Two-Feet-Nine seam and 91 men on the surface while the No.4 Pit employed 657 men working the Yard and Bute seams and 169 men on the surface of the mine.

In 1955 the colliers at this colliery were receiving an average payment per shift of fifty-five shillings compared to the Rhondda colliery’s average of fifty-two shillings per shift. In 1955 out of a total colliery manpower of 2,003 men, 1,227 of them worked at the coalfaces, this figure dropped during the latter 1950s to 1,117 on the coalfaces in 1956 and 935 men in 1958. In 1956 the price list negotiated for the five feet thick ‘Dip Seven’ seam was three shillings and sixpence per square yard (one ton) of hand-cut coal. In 1957 the NUM Lodge at this colliery had 331 unemployed members –the highest number of any lodge in South Wales. In 1961 the Nos. 1 & 4 Collieries were still in the No.3 Rhondda Area’s, No.3 Group along with Gelli Colliery, the total manpower for the Group was 2,162 men, while total coal production for the year was 396,828 tons. The NUM Lodge Secretary in 1964 was Garfield Rogers.

Melville Banbury worked at Cambrian in the 1960s, this is his story as told to the Glo (National Mining Museum of Wales) Magazine:

I left school at 15 years and after attending Wattstown Training Centre, went to work in Cambrian Colliery…I worked on both hand-cut and machine cut faces. I wouldn’t go back for a thousand pounds a week to be honest because I saw so many accidents – life was cheap! In spite of everything, miners were fantastic to work with. We were like brothers and it made up for the awful working conditions…I had a very bad accident at Cambrian, it was 1st. March 1963 and I was working on developing a new coal face. We had bored the shot holes the day before and I wanted to blow the five holes on the left-hand side of the face first. The fireman wasn’t happy as he wanted to blow the lot down in one go but he gave in and charged up as I wanted. After he had charged up he found out that he didn’t have his shot firing battery with him so he went back in the roadway to look for it. While he did this we carried on working. There was a roof support which was stuck in the floor and we had a lot of trouble trying to get it out. So I had both arms around the post trying to work it loose and the next thing that I remember was feeling the sides of a hospital bed and wondering where I was.

I said where am I too, and I heard a rustle of feet coming towards me. I was in a ward on my own and had just come out of unconsciousness. I had a smashed face and I was blind, my wife later told me that I had been in hospital for a good couple of days. I had almost been given up for dead, in fact, the Rhondda Leader had actually reported that I had died. The two men that I was working with had also gone to hospital but I had been injured the worse as I was right up against the shot holes. There was a court case eventually. The shots man claimed that he had told us to take cover, he was trying to save his job blaming us but, after a day-long trial he was found guilty. I never again worked underground after that accident.

I had a lot of problems after the accident and went back and fore the hospital for seven years. The doctor told me not to work again, but I wanted to do something. I had a word with Reg Turner the lodge secretary and he asked if I would like to go as a handyman in the NCB Llanishen offices, down there they told me that part of the job was cleaning the bosses cars, but I said if they liked driving in those big cars they should clean them themselves. Then I was told to apply for an assistant gardeners job in Talygarn Miners Rehabilitation Centre near Pontyclun. I started in June 1970, I loved the job and my health improved a lot.

On the 26th of August 1966, the NUM members at this pit held a one day token strike over notices being issued that the pit would shut on September 24th. The men had refused to answer earlier letters from the NCB which asked them which colliery they wished to be transferred to against the advice of the South Wales Area of the NUM. The local lodge then urged the South Wales executive of their union to support their campaign to take industrial action to keep the pit open but this was rejected by the area executive council.

On the 21st of July 1966, the NUM took their case for keeping the pit open to the then Chairman of the National Coal Board, Lord Robens. The No.1 Pit was then working the Pentre seam and the No.4 Pit was working the Nine-Feet seam. It was reported that the Pentre seam was only 30 inches thick and only 70% of it was saleable, the only reserves left were 500,000 tons. To further develop the Nine-Feet seam the NUM requested funding to the extent of £170,000. The NCB decided that this was too risky with Robens stating that “£1 million has gone down the drain in the last four years.” It was further stated that the pit needed manpower of 842 to be viable and it only had 660 men. The colliery was closed by the National Coal Board on the 24th of September 1966 for economic reasons. It was working the Two-Feet-Nine seam on closure.

There were two major disasters at this pit, on the 10th March 1905, on the nightshift, the men were starting to go down the shafts when there was an explosion in the pit-bottom area that killed 33 miners and seriously injured another 11. On the 17th May 1965, another explosion killed 31 men. A combination of a faulty electrical switch and a defective ventilation door was deemed to have caused this explosion.

Some of the others who died at these pits:

- 16/04/1891, George Davis, Age: 19: Collier: Killed on the spot by the fall of a piece of roof.

- 16/05/1891, William Wheeler, Age: 17: Door boy: Caught by a journey on the engine plane as it was passing the door which he attended.

- 25/7/1891, David Rees Age: 30: Sinker: Fell down the sinking shaft.

- 1/11/1891, Lewis Roberts, Age: 30: Labourer: Crushed by cage descending upon him.

- 29/01/1892, John Parry, Age: 60: Rubbish tipper: Crushed between two trams.

- 22/02/1892, Isaac Griffiths, Age: 35: Collier: Fall of coal.

- 7/04/1892 William Evans, Age: 29: Assistant Hitcher: Struck by a piece of coal.

- 8/08/1892, John Rowlands, Age: 22, Evan Hughes, Age: 22: Sinkers: Fall of brickwork from arching in shaft.

- 23/03/1893, William Martin, Age: 38: Haulier: Found fatally injured between a tram and a pair of timbers.

- 15/6/1893, Samuel Williams, Age: 67: Road cleaner: Found dead having been run over by a journey.

- 20/10/1893, David Davies, Age: 28: Repairer: While repairing a small stone fell on his head, cutting it. He died from inflammation of the brain nine days afterwards.

- 25/10/1893, David Howells, Age: 40: Master haulier: Kicked by a horse in the stable while attempting to raise another horse which had fallen in front of the stall.

- 6/06/1893, William Evans, Age: 68: Road cleaner: Was knocked down by a horse and tram on a dip road. The horse had been left by the haulier in charge and was startled by some small stone.

- 19/01/1894, David Owen, Age: 60: Labourer: Crushed between two loaded trams. While in act of turning one tram on turntable, another tram ran against him.

- 22/05/1894, Edward Jones Age: 54: Doorkeeper: Run over by an empty journey.

- 30/05/1894, James Palmer, Age: 22: Trimmer: In attempting to jump from one waggon to another he fell under the waggon which passed over.

- 4/06/1894, Richard Griffith, Age: 50: Repairer: In attempting to cross a fall of roof which he had brought down by cutting out some timbers he struck against an old lag and brought a second fall upon him.

- 10/09/1894, Richard Cooper, Age: 28: Repairer: Fall of roof on road.

- 28/11/1894, Edward Rees, Age: 26: Sinker: While deceased and two others were fixing a stage in the shaft at the five feet seam he fell off the beam on which he was standing into the sump and was drowned. The water was only 9ft. deep and the top of it 4 ft. below the stage.

- 1/01/1895, Benjamin Jones Age: 24: Rider: While riding inbye on the last tram of the journey with a tram loaded with 9 feet of timber in front one of the props was jerked across the road and struck him.

- 13/01/1895, Elias Evans, Age: 42: Mason: Whilst standing on bowk at six feet landing he was alarmed by an icicle falling down shaft and in attempting to step off on to landing a distance of 1 foot 9 inches his foot slipped and he fell back into sump.

- 23/01/1895, John Radford, Age: 59: Assistant repairer: Fall of roof in a rubbish stall

- 26/6/1896, William Williams Age: 35: Collier: Fall of coal at face

- 25/07/1896, John Thomas, Age: 73: Fitter: While examining steam-pipes at six feet landing deceased fell off a beam into the shaft which is sunk 120 yards further.

- 20/08/1896, William Jones, Age: 35: Day overman: While deceased and the fireman were riding in last tram of a journey it was thrown over by some props which had fallen off a tram in front.

- 5/10/1896, John Jones Age: 30: Assistant ripper: Died on 13th Oct. from erysipelas from injury to head blow from a prop

- 22/03/1897, W.F. Pratt, Age: 30: Points man: A shackle opened and seven trams ran back over him. 25/08/1898, Thomas Hockey, Age: 40: Collier: Run over by journey while passing out.

- 15/09/1898, Joseph Radford, Age: 35: Hitcher: He pushed an empty tram forward into the open shaft at the Red Coal landing and fell after it to the bottom.

- 19/11/1898, William Griffiths Age: 13: Assistant haulier: Crushed between an empty tram and a cog at the mouth of a stall a full tram in passing having caught the empty.

- 25/11/1898, John Llewellyn, Age: 21: Timberman: Killed by a large fall on a road while it was being repaired and before some new timbers had been properly secured.

- 16/5/1899, Daniel Morgan, Age: 40 Collier: Fall of side at face.

- 17/05/1899, R. Griffiths, Age: 15: Assistant haulier: Fall of roof at on road cliff 12ft. x 4ft. thick while walking out of main return two pairs of timber broke and a fall occurred.

- 22/06/1899, Bertie Mills, Age: 14: Assistant haulier: Fall of roof at face.

- 14/09/1899, Morgan Morgan, Age: 53: Collier: Fall of side at face.

- 27/09/1910, John Powell, Age: 23: Collier: Fall of roof at working face.

- 5/01/1912, William L. Evans, Age: 23: Screen fitter: He was caught in machinery.

- 12/02/1912, Albert Bevan, Age: 19: Collier: Fall of roof at working face.

- 16/04/1912, John West, Age: 27: Barry shifter: In trying to stop a runaway horse, he was run over.

- 1/05/1912, Eleazor Fowler, Age: 57: Wagon repairer: He was killed by being crushed, or run over, whilst repairing wagons on a colliery siding road.

- 24/06/1912, Benjamin Wilson, Age: 26: Rider: Noticing that some of the trams of his empty journey were off the rails, he fell underneath as he attempted to get out of the tram he was riding.

- 15/07/1912, William Jones Age: 22: Clipper: He was injured by being overtaken by a horse and full tram on a heading road. He died on 21st July 1912.

- 27/07/1912, Thomas Minham, Age: 27: Collier: Fall of the side at the working face.

- 21/4/1913, W.R. Davies Age: 36: Master haulier: Struck on the leg by sheaves. Died 9th July.

- 28/5/1913, David Davies Age: 46: Repairer: Fall of the roof on haulage road.

- 14/08/1913, Stanley Jones Age: 21: Haulier: As he was bringing out a loaded train from the face, he lost his light; as he was walking in front of his horse he jumped to the side of the road and was crushed between the tram and a narrow place of the heading.

- 15/08/1913, George Salter, Age: 54: Shifter: When repairing the road on a double parting three trams were let down on him killing him.

- 4/11/1913, Samuel Baker, Age: 31: Night repairer: Fall of the roof.

- 30/12/1913, Thomas Thomas Age: 67: Shifter: Fall of the roof in the rubbish road.

- 14/01/1914, Cornelius Jones Age: 34: Repairer: He was crushed against the side by an empty journey which ran wild owing to the breakage of the hauling rope. He died on January 18th.

- 3/7/1914, Lewis Williams, Age: 30: Repairer, John Davies Age: 42: Assistant repairer: Fall of roof and side.

- 24/7/1914, Robert Williams Age: 25: Rope changer: He was caught and fatally injured by a runaway journey of trams owing to a shackle pin rising. He died the same day.

- 30/09/1914, John Lewis, Age: 30: Haulier: Fall of the roof in stall road.

- 1/2/1928, Lawrence Davies Age: 44: Collier: Fall of stone. Died 3rd.

- 14/03/1928, Charles Thomas, Age: 32: Haulier: Crushed between tram and side.

- 20/3/1928, Walter James Griffiths Age: 14: Labourer: Unloading timber when he fell over the wagon. Died 21st.

- 28/9/1929, Alfred Williams Age: 60: Collier: Fall of coal. Died 30th.

- 10/10/1929, John Evans, Age: 58: Pulleyman: Caught between empty trams.

- 4/12/1929, Albert Biddle, Railway guard: Caught between buffers and wagon.

- 19/11/1930, A. Barlthorp, Age: 17: Assistant collier: Crushed by tram.

Some Statistics:

- 1899: Manpower: No.1: 1,015. No.2: 1,262. No.3: 390.

- 1900: Manpower: No.1: 928. No.2: 1,294. No.3: 372. Surface: 438.

- 1901: Manpower: No.1: 783. No.2: 1,357. No.3: 310. Surface: 36.

- 1902: Manpower: 3,052.

- 1903: Manpower: 3,335.

- 1905: Manpower: 3,168.

- 1907: Manpower: 3,758.

- 1908: Manpower: 4,054.

- 1909: Manpower: No.1: 701. No.2: 1,498. No.3: 1,855.

- 1910: Manpower: No.1: 710. No.2: 1,498. No.3: 1,855.

- 1911: Manpower: No.1: 724. No.2: 1,528. No.3: 1,860.

- 1912: Manpower: No.1: 731. No.2: 1,613. No.3: 1,961.

- 1913/5: Manpower: No.1: 500. No.2: 1,613. No.3: 2,000.

- 1916: Manpower: No.2 1,613. No.3: 2,000. Output: 986,000 tons.

- 1918: Manpower: No.1/3: 2,141. No.2/4: 1,238. Surface: 654.

- 1920: Manpower: No.1: 400. No.2: 1,200. Nos. 3/4: 1,900.

- 1922: Manpower: No.1: 400. No.2: 1,200. Nos. 3/4:1,900.

- 1923: Manpower: No.1: 1,392. No.2: 1,678. No.3: 1,147. No.4: 681. Output: 1,000,000 tons.

- 1924: Manpower: No.1: 1,812. No.2: 1,119. No.4: 815.

- 1925: Manpower: 3,900.

- 1927: Manpower: No.1: 600. No.2: 498. No.3 & 4: 900.

- 1928: Manpower: 2,049.

- 1929: Manpower: 1,950.

- 1930: Manpower: 1,749. Output: 600,000 tons.

- 1931: Manpower: 1,950.

- 1932: Manpower: 1,500.

- 1933: Manpower: 2,274.

- 1934: Manpower: 2,170. Output: 550,000 tons.

- 1937: Manpower: 1,631.

- 1938: Manpower: No.1: 402. No.2: 1,364.

- 1940: Manpower: 1,424.

- 1941: Manpower: 1,463.

- 1942: Manpower: 1,493.

- 1944: Manpower: 1,486.

- 1945: Manpower: 1,336.

- 1947: Manpower: No.1: 169. No.2: 503. No.4: 1,067.

- 1948: Manpower: 1,780. Output: 425,000 tons.

- 1949: Manpower: 1,810. Output: 572,000 tons.

- 1950: Manpower: 1,823.

- 1953: Manpower: Output: 502,500 tons.

- 1954: Manpower: 1,996. Output: 441,066 tons

- 1955: Manpower: 2,003. Output: 430,035 tons.

- 1956: Manpower: 2,006. Output: 391,256 tons.

- 1957: Manpower: 1,951. Output: 408,570 tons.

- 1958: Manpower: 1,829. Output: 361,838 tons.

- 1959: Manpower: 1,729. Output: 318,696 tons.

- 1960: Manpower: 1,557. Output: 307,368 tons.

- 1961: Manpower: 1,549. Output: 315,687 tons.

- 1962: Manpower: 1,600. Output: 313,365 tons.

- 1963: Manpower: 1,474. Output: 272,325 tons.

- 1964: Manpower: 1,051. Output: 250,531 tons.

- 1965: Manpower: 778. Output: 190,079 tons.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

The plans below have been provided by Lee Reynolds and used here with his permission.

All seams composite plan

2 foot 9 Seam

5 foot Seam

Lower 9 foot & Bute Seams

Upper 9 foot Seam

Bute Seam

Red Vein

Yard Seam