CYNHEIDRE-PENTREMAWR. Llanelli, Carmarthenshire. 6th. April, 1971.

Cynheidre Colliery was in the West Wales Area of the National Coal Board and was five miles north of Llanelli on the western extremity of the coalfield. Cynheidre and Pentremawr Collieries were linked underground in 1966 and came under the same manager in 1970. The Pentremawr Colliery began production in 1875. The sinking of the shafts at the Cynheidre Colliery was started in 1954 and production began in 1960. At the time of the outburst, the combined colliery produce about 20,000 tons gross each week and employed 1,178 men underground and 422 on the surface.

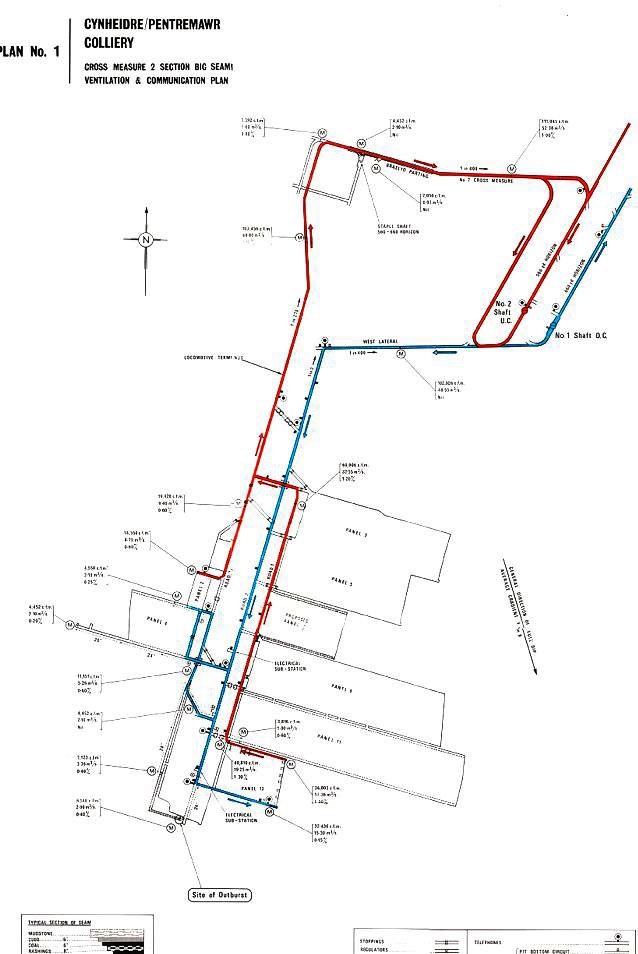

There were two downcast shafts, two upcast shafts and three intake drifts all within a radius of 1.5 miles. The No.1 downcast and the No.2 upcast shafts were 24 feet and 20 feet in diameter respectively and were both at Cynheidre. The No.3 upcast and No.4 downcast shafts each of 18 feet diameter were three miles to the north-east of Cynheidre, near Tumble. The No.2 upcast shaft was equipped with an electrically driven Davidson Sirocco fan extracting 370,000 cubic feet of air per minute at 8 inches water gauge.

Approved electric cap lamps were in general use and flame safety lamps were issued to officials and selected workmen as firedamp detectors. Methanometers were carried and used by the ventilation staff and certain senior officials. The colliery was divided into five main sections each of which had a separate ventilation circuit. The outburst occurred in the Cross Measure 2 Section of the mine.

The principle officials were the Area Director, Mr. D. Davies, the Deputy Director (Mining), Mr. R. Williams, chief Mining Engineer, Mr. G. Hodkin, deputy Chief Mining Engineer (Mining Services), Mr. C.J. Davies and the Deputy Chief Mining Engineer (Mining Planning and Surveying), Mr. T. Rosser. The colliery was managed by Mr. C.B. Jenkins with two deputy managers, Mr. W.J. Williams for the Cynheidre part and Mr. K.V. Jones for the Pentremawr. The undermanager in the Cross Measure 2 Section was Mr. P.K. Lewis. On the day of the disaster, Mr. W.J. Williams was in charge of the colliery while the manager was away on official business in the West Midlands. Mr. Jenkins was called as soon as the incident occurred and arrived at the colliery in the early morning.

All the seams worked at the colliery were of high-grade anthracite and they were in descending order, Big, Ddugaled, Stanllyd, Braslyd, Gwendraeth and Pumpquart but since 1966 only the Big Seam had been worked. The roof in this seam varied from massive sandstone to shale and the floor was a weak fireclay, in general, the workings were dry and throughout this part of the coalfield there is geological faulting and folding and there were areas where the coal was pulverised and powdery. Outbursts had been experienced in this part of the coalfield which ejected coal and firedamp. The amount of coal varied from a few tons to thousands of tons and the total quantity of firedamp bore a relationship to the tonnage of coal ejected.

An outburst usually lasted for a very short time and was usually preceded with a warning noise called “pouncing”. This noise was compared with that of a two-stroke motorcycle starting and accelerating. The firedamp was usually released with considerable violence and the coal ejected was invariably very finely powdered. Since the early years of the century, 192 incidents of this type had been recorded in the West Wales area and had occurred at nine mines in the Gwendraeth Valley. At the Ponthenry Colliery, a drift mine on the outcrop about two miles to the north-west of the Cynheidre Nos. 1 and 2 shafts there were a number of serious outbursts in the 1920s which caused loss of life and as a result of these accidents, a code of Special Regulations was established under Section 87 of the Coal Mines Act, 1911. This mine ceased production in 1930 because of the difficulties in dealing with these outbursts. The problem returned to other collieries in West Wales, periodically, over the next twelve to fifteen years.

An increasing number of incidents resulted in the formation in 1945 of the Joint Advisory Committee on Outbursts on which the Mining Inspectorate, the Management and the Trade Unions were represented. This Committed produced Codes of Practice which recommended precautions to prevent outbursts and to minimise the consequences if they occurred. The code recommended a shot firing procedure designed to induce an outburst where conditions were suspect which was only practice when there were no people on the return side of the workings. This technique was known as volley or induced shotfiring. In the Cynheidre part of the colliery, the first outburst of coal and gas occurred in October 1962 and since then there were 67 outbursts. In the Big Seam there were 37, 13 of which occurred spontaneously and the remainder were induced by shotfiring.

The Cross Measure 2 Section of the mine was developed from two main roadways driven from the 560 yards and 660 yards horizon laterals from the Nos.1 and 2 shafts respectively. When the Big Seam was reached a longwall face was opened out and advanced to the dip forming three roadways from which subsequent production faces were worked on both flanks. The development road was serviced by a centre intake, Road 2, with returns on the left side, Road 1 and on the right side, Road 3. In 1968 it ceased production because of geological difficulties and later the inbye portions of the roads became untravellable. Road 1 became closed inbye of Panel 11, Road 2 inbye of Panel 13 and Road 3 inbye of Panel 4. In the intervening period flank faces were worked and Panel 13 and Panel 2 were in production at the time of the outburst. In order to re-establish the ventilation in this forward development area two coal headings were started, one at the inbye end of the Road 2 and one re-opening Road 3. They were being driven by outside contractors.

Panel 13 was a longwall face 130 yards long, advancing slightly to the dip with a gradient on the face of 1 in 12 from the return to the intake. Coal was being produced on the day and the afternoon shifts using a 125 horsepower ranging drum shearer loader which extracted the top seven feet six inches of the seam. The mudstone roof was supported by six-legged powered supports. The main conveyor gate was supported by 14 feet by 11 feet arched girders and had a coal rib on the right-hand side and a five-yard pack to the other. The return supply gate was 12 feet by 9 feet supported by arched girders with a four-yard pack o the right-hand side and skirting the partially closed roadway which served Panel 11. Production commenced on 8th. February 1971 and the face was soon advancing at a regular rate giving an output of up to 12,000 tons per week.

The Road 2 Cross-cut Drivage, in which the outburst occurred, started from the far side of Road 2 and was being driven roughly parallel to the old face line leaving a pillar about eight yards wide. It had been advanced for about 16 yards in the seam and was supported by 12 feet by 10 feet arches, The coal was won by explosives fired in large rounds between shifts in accordance with the Outburst Code and was filled on to a conveyor by a compressed air powered shovel loader. The heading was worked on three shifts and advanced about 4 feet per shift. The depth of cover at this point was 680 yards. Until shortly before the incident the conditions on the face were considered normal and there was no visible geological disturbance and the coal itself appeared strong.

The total quantity of air entering the main intake lateral to the Cross Measure 2 Section of the mine was 102,926 cubic feet per minute and when last measured, 32,436 cubic feet per minute reached the face of Panel 13. In the shifts before the outburst work on the Road 2 Cross-cut Drivage proceeded as usual on the day shift of 5th. April. The loose coal got out by the previous shift was filled out, the four feet advanced and an arch girder was set. The coal was bored in preparation for shotfiring between the day and the afternoon shifts. The shotfirer, D. Lydon Davies, was killed but records showed that he fired a volley round of 12 shots containing 18 pounds of Group P5 explosives. In accordance with the Code of Practice, this operation was carried out with no men at all downwind in case the shock of the shots would cause an outburst but no outburst occurred.

When the afternoon shift of the 5th April arrived at the face of Road 2 Cross-cut Drivage, they found that the shotfiring had produced an unusually large amount of loose coal and the work of filling went on throughout the shift. Because of the quantity of the coal, the advance was not enough to permit an arch to be set. The coal had produced more dust than usual and much time was spent watering it with sprays to keep this down. The deputy in charge of the heading, Edgar John Evans, noted that the coal was falling off the face and sides, particularly on the left-hand side so that the face at roof level was six to seven feet in advance of the last arch by the end of the shift and there were signs that the roof was beginning to rise slightly. He made tests with flame safety lamps but found no increase in the percentage of firedamp during the shift, Neither the deputies or the workmen heard any “pouncing” and they attached no significance to the change in the conditions.

The workmen on the night shift of the 5-6th April, continued filling the loose coal which was still falling from the face and sides and eventually were able to set another arch. The deputy in charge, Glyn Howell Jones, confirmed that the coal was dusty and friable and when he left the heading at 5.15 a.m., the face at the roof level was about 9 feet ahead of the most recently set arch. By this time an abnormality was clearly visible with the roof rising away sharply about 1 in 3. The falling coal on the left-hand side had also produced a space of about 9 feet behind the arch at roof level. During the shift, the deputy did not detect any firedamp using a flame safety lamp. On reaching the surface at the end of the shift the deputy reported the conditions in Road 2 Cross-cut to P.K. Lewis, undermanager and W. Luther Davies, the day shift overman who was later killed in the accident and John Jones Rees, the oncoming deputy.

During the day shift of 6th April normal operations proceeded on Panel 12 and Panel 2 and Road 3 Development. In Road 2 Cross-cut Drivage two contractors workmen, A.G. Miller and H. Itzi, continued to fill loose coal at the face of the heading and to pack material behind the arches. In the course of the morning, the heading was inspected by P.K. Lewis, and John Jones Rees, W. Luther Davies, overman, D. Lyndon Davies, shotfirer, F. Knoedl, contractors engineer and J. Steinmann, contractors shift supervisor. When John Jones Rees arrived at the face of Road 2 Cross-cut Drivage at about 8.30 a.m., he found conditions much the same as the night shift deputy and reported to him. The coal was soft and dusty and still falling from the side and face. The ventilation conditions were normal and he did not hear any “pouncing”. He left the heading at about 9 a.m. to inspect other parts of his district, leaving the workmen to fill loose coal into bags and pack them behind the arches. He expected this work to occupy the whole shift and did not return before the outburst.

The same conditions were observed by J. Steinmann who entered the drivage at about 8.30 a.m. and remained until about 9.30 a.m. P.K. Lewis, undermanager and W. Luther Davies, the overman, arrived at the drivage at about 10 a.m. According to Lewis, they found that the coal had fallen from the face for about 10 feet forward of the last arch at roof level and the roof curved upwards to a height of about 4 feet above the normal. Using a methanometer he found that the firedamp content near the face of the heading was normal at 0.20 percent. He told the workmen to get nine feet long, flat timbers and place them behind the arches to support the bags of coal dust. Lewis telephoned for the surveyor to record the disturbance of and spoke to D. Austin Thomas who was an expert on outbursts and asked him to make an inspection and give his opinion on the conditions. Neither of these men arrived before the outburst occurred. Lewis left the No.2 Cross-cut Drivage about 10.30 a.m. and summoned F. Knoedl and gave him instructions concerning the work to be done in the drivage. Knoedl had made three earlier visits to the drivage and after receiving the instructions from the undermanager, arrived at the face of the headings soon after 11 a.m. At that time, the workmen were cleaning up and using hand shovels in the final stages of preparing to set an arch on the instructions of the undermanager and the shovel loader was not in use. Shortly before leaving the place, Knoedl saw a workman’s flame safety lamp hanging near the face and noted that the flame was burning normally. When he left the drivage, two workmen, Miller and Itzi were near the face and A. Lydon Davies, a shotfirer had come in. He was near the drive-head of the conveyor serving the drivage and it was then 11.50 a.m. about 10 minutes before the outburst occurred.

At about 12 noon the outburst of coal and firedamp occurred at the face of the Road 2 Crossing-cut Drivage. All the people working there were killed. These were D. Lydon Davies, A.G. Miller and H. Itzi. The facts that their bodies were recovered some distance from the working face well clear of the outburst of coal, suggested that they had some warning and were trying to escape when they were overcome and asphyxiated.

Denzil Rees, a transfer point attendant on Road 2 at the junction with Panel 13 Main gate, was working about 20 feet inbye the auxiliary fan which ventilated the No.2 Cross-cut drivage when he heard a fizzing sound as if something was passing through the fan duct and saw a cloud of dust coming towards him from the fan. He saw the flame in his lamp rise and he extinguished it as he became aware of a sulphurous smell coming from the direction of the No.2 Cross-cut drivage. Rees and D. V. Callahan, supplies man, and Dewi D. Evans and R. Sandow, repairers, were working near Rees, realised that something serious was wrong and rushed outbye along the Road 2. They were joined by five electricians and four other workmen who were having a food break at the substation about 40 yards outbye of Panel 13 junctions. These 14 men managed, with some difficulty, to travel outbye and reach the fresh air intake. The firedamp from the outburst had backed up against the intake air current for 140 yards outbye of Panel 13 junction. One man in this group, Gordon M. Rowlands, an electrician, had the presence of mind to continue further 200 yards beyond Panel 11 gate junction to a substation where he switched off the power supply to Panel 13 and Road 2 Cross-cut Drivage.

Firedamp from the outburst was carried along Panel 13 main gate towards the face. About 40 yards along this road there were two repairers, F.R. Ould and Thomas Li. Rees and a shotfirer, David J. Thomas. They noticed a bad smell and saw a cloud of dust coming towards them. They realised that something was wrong and struggled outbye through the cloud of dust to Panel 13 gate junction where they all remembered climbing over travelling bridge across the main conveyor belt. After that they lost consciousness for a short period of time but came round and travelled out along Road 2 as far as Panel 11 gate junction, keeping as close to the floor as possible. Here, they met a group of men who had fresh air from the return side of Panel 13 as well as those who had gone before them from Road 2. V. Lewis, a beltman, who was working about halfway along Panel 13 main gate recalls seeing a cloud of dust before he became unconscious. When he came to some time later, he began to struggle out and remembered that there was a compressed air valve near the ripping gate and opened it to get fresh air. When he was sufficiently recovered he continued outbye.

In Panel 13 main gate there were about 25 men from about 40 yards outbye from the face to a point a few yards along the face. After a short period of warning smell, all these men lost consciousness. There was evidence that some of them had time to travel a few yards from the face into the gate but others appeared to have been overcome very quickly. Three of these men did not recover, W. Luther Davies, overman, I. Gareth Watkins, ripper and H. Garfield Roberts, measurer. The first to regain consciousness was Tom Lewis who was a few yards along the face. He saw several men unconscious around him and attempted to rouse them. Some of them came to and others did not. He went to the gate and telephoned direct to the surface First Aid Room and spoke to Noel Davies. This call was the first indication to the surface that there was something seriously wrong below ground. Soon after the call was made some of the men began to recover amongst them P. Lewis, the undermanager who realised that there had been an outburst. His first action was to speak on the district loudspeaker to warn everyone to get out to fresh air. He then telephoned the surface and spoke to W.J. Williams, the acting manager who put the emergency scheme into operation.

In Panel 13 main gate there were about 25 men from about 40 yards outbye from the face to a point a few yards along the face. After a short period of warning smell, all these men lost consciousness. There was evidence that some of them had time to travel a few yards from the face into the gate but others appeared to have been overcome very quickly. Three of these men did not recover, W. Luther Davies, overman, I. Gareth Watkins, ripper and H. Garfield Roberts, measurer. The first to regain consciousness was Tom Lewis who was a few yards along the face. He saw several men unconscious around him and attempted to rouse them. Some of them came to and others did not. He went to the gate and telephoned direct to the surface First Aid Room and spoke to Noel Davies. This call was the first indication to the surface that there was something seriously wrong below ground. Soon after the call was made some of the men began to recover amongst them P. Lewis, the undermanager who realised that there had been an outburst. His first action was to speak on the district loudspeaker to warn everyone to get out to fresh air. He then telephoned the surface and spoke to W.J. Williams, the acting manager who put the emergency scheme into operation.

There were 18 men at the return end of the face near the return gate roadhead. The overman, Illtyd Beynon, was on the face nearby when he noticed a smell. He immediately checked the conditions with his methanometer which showed 5 per cent firedamp. He quickly got the men together and told them to get out of the return gate into the main intake as fast as they could. After checking for lights on the face, Beynon followed the group out to the main intake at Panel 11 junction. On the way he collected two repairers working in the old Panel 11 main gate.

Two powered support operators, B. Griffiths and W.C. Davies were the only men between the groups at each end of the face. They were overtaken by a cloud of dust about one-third of the way along the face. They realised that something serious had happened and went up the face and out by the return gate. They managed to reach the outbye end of the gate with great difficulty and from there they were assimilated into the Road 2 main intake.

Two contractors workmen S. Parry and B. Barskyj who were working at the face of Road 3 drivage heard a rumbling noise and retreated with alarm about 40 yards. They then realised that the auxiliary fan ventilation the drivage had stopped, and they went outbye to the nearest connection with Road 2. They met J. Steinmann who was their supervisor who told them there had been an outburst and instructed the men to warn two back rippers in Road 3 and the men in Panel 2. The back rippers in turn, warned L.R. Jones, overman and D. Deasy, deputy at the transfer point of Panel 2 gate L.R. Jones the organised the withdrawal of all 16 men in Panel 2. Some of these men went to help in the rescue operations in Panel 13 gate.

Along the return airway from Panel 13 outbye to the locomotive terminus there were four engine houses for haulages handling supplies. Loudspeakers were installed near three of these haulage engines and seven men who were working there at the time of the outburst heard the warning given on the system and went through the cross heading which led to the main intake near the top of the 1 in 2 drift. They reached the intake air without suffering any adverse effects. At the fourth haulage engine house further inbye on Road 1, there was no loudspeaker and two supplies men, A. Mount and D.T. Jones and a haulage driver, C. Evans, did not realise that there was an emergency and remained there until their deputy sent them to the intake. The last people to be involved in the incident were the locomotive driver and a guard in the No.7 Cross Measure. They were travelling inbye from the pit bottom with an empty diesel locomotive when the engine began to loose power. The driver stopped the engine and noticed a dust cloud passing them. The guard said that the flame traps on the exhaust had been smoking. They felt that the air was warm and there was a smell of mildew but at this stage they were not alarmed and were concerned with the breakdown of the locomotive. They walked out a junction and reported by telephone to the locomotive fitter. The fitter and driver returned to the locomotive but could not find the problem. They managed to start the engine and nursed it back to the garage which was in fresh air and the engine started to run normally. They then left the mine. About half an hour later 7 per cent firedamp showed at the outbye end of that return main roadway.

The men involved in the outburst made their own escape as best they could. After, those who were physically fit helped those who needed assistance. The group of 18 men at the return end of Panel 3 led by the deputy Illtyd Beynon were soon on fresh air and he used the loudspeaker system to broadcast a message instructing all the men to get out of the return airways. He tested for gas using his methanometer and found none and then went down Road 2 towards Panel 13 main age where he found 5 per cent of firedamp. He returned to the junction and telephoned the acting manager at the surface and reported to him. Beynon made a second attempt to go down Road 2 and found 4.5 percent firedamp but when he saw the lamps of F.R. Ould, D.J. Thomas and T.L. Rees coming towards him he realised that the air was breathable. With six men, he went inbye down Road 2 as far as the junction with Panel 13 main gate where he found 5 per cent and again reported by telephone to the acting manager who told him that P.K. Lewis, the undermanager, was at the inbye end of Panel 13 main gate with a large number of men who were in various stages of regaining consciousness.

When Leslie Davies, the first survivor from the inbye end of Panel 13 main gate, reached Road 2, Beynon decided to lead his group of volunteer’s rescuers to the Panel 13 face. On their way, they met survivors coming out and face what assistance they could to get the men to the fresh air in Road 2. Near the face Beynon met Lewis who had recovered and was supervising the rescue operations. He had crawled out into the main gate and helped the men as they recovered consciousness. As soon as everyone appeared fit enough he sent them outbye telling them to keep as close to the floor as possible.

Soon after Beynon and his group arrives, L.R. Jones, overman, and D. Deasy, a deputy came up from Panel 2 which had not been affected directly by the outburst. They were followed by first aid men from the surface carrying oxygen apparatus. It took about an hour to evacuate all the survivors from this area but despite long efforts with oxygen apparatus W. Luther Davies, H. Garfield Roberts and I. Gareth Watkins did not respond. The assisting workmen began to feel the effects of the gas and the undermanager decided that all should withdraw into fresh air.

While the evacuation from the Panel 13 main gate was going on, another group including F. Knoedl, J. Steinmann. G.M. Rowlands and Oscar Evans arrived at the outbye end of the gate and saw light not far away down the lower past of Road 2. They held their breath and kept as close to the ground as possible and working rapidly, they were able to bring out A. Miller and Lyndon Davies to e junction where they attempted to revive them but without success. They tried to go further down to recover H. Itzi but were prevented from doing so became of high concentrations of firedamp.

The acting manager had called the Loughor Rescue Station which was 10 miles away at 12.26 p.m. and the first team arrived at the colliery at 12.50 p.m. and went underground soon afterwards. They made a fresh air base in Road 2 at the junction with old Panel 11 gate. Soon after 2 p.m. another team arrived at the fresh air base and exploration of the affected air was started by men wearing breathing apparatus. By 2.15 p.m. The last of the survivors had been evacuated and all the men in the mine were accounted for. The rescue teams recovered the bodies from Panel 13 main gate and by 3.40 p.m. Five of the bodies had been brought out into Road 2 and the fresh air base moved outbye of Panel 13 main gate junction. Soon afterwards the body of H. Itzi was brought out. The rescue teams then made inspections down Road 2 through the whole of the Panel 13 district and finally through the return from panel 13 to the upcast shaft.

Those killed:

- Douglas Lydon Davies aged 54 years, shotfirer,

- William Luther Davies aged 56 years, overman,

- Henryk Itzi aged 45 years, contractor’s workman,

- Albert George Miller aged 35 years, contractor’s workman,

- Henry Garfield Roberts aged 61 years, measurer,

- Ieuan Gareth Watkins aged 43 years, ripper.

Those who were injured:

- James Edward Alderton aged 28 years, powered support operator.

- Illtyd Benyon aged 34 years, overman.

- Daniel Vivian Callahan aged 40 years, supplies man.

- Leslie Davies aged 55 years, ripper.

- Morley Rhys Davies aged 55 years, ripper.

- Thomas Howell Davies aged 53 years, supplies man.

- Wiliam Aled Davies aged 33 years, assistant fitter.

- William Cliff Davies aged 54 years, powered support operator.

- William George Davies aged 56 years, beltman.

- Vivian Denning aged 35 years, powered support operator.

- Cyril Evans aged 52 years, haulage driver.

- Derwyn Morris Evans aged 55 years, stableman.

- Dewi Daniel Evans aged 41 years, repairer.

- Eifion Morris Evans aged 21 years, electrician.

- John Thomas Evans aged 54 years, shotfirer.

- Kenneth John Evans aged 45 years, stableman.

- Alun James Gibbeard aged 39 years, locomotive fitter.

- Brinley Griffiths aged 48 years, powered support operator.

- Ramsey Gordon Hughes aged 53 years, transfer point attendant.

- Thomas William Hurley, aged 45 years, powered support operator.

- Dewi John aged 50 years, repairer.

- David Bryan Jones aged 32 years, supplies man.

- David Gwilym Jones aged 34 years, shearer operator.

- David Kenneth Jones aged 41 years, powered support operator.

- David Thomas Jones aged 58 years, supplies man.

- Dennis John Jones aged 39 years, ripper.

- Emrys Jones aged 43 years, deputy.

- Robert Jones aged 36 years, deputy.

- Sidney Jones aged 42 years, stablemen.

- Thomas Daniel Jones aged 44 years, stableman.

- Verdun Jones aged 54 years, general worker.

- Fritz Knoedl aged 40 years, contractor’s engineer.

- Ieuan Marvin Lewis aged 35 years, ripper.

- Phillip Kenneth Lewis aged 33 years, undermanager.

- Tom Lewis aged 46 years, powered support maintenance man.

- Vincent Lewis aged 54 years, beltman.

- Bertie Irfon Miles aged 49 years, ripper.

- Haydn George Mills aged 36 years, fitter.

- Robert Phillip Morgan aged 29 years, stableman.

- Anthony Mount aged 55 years, supplies man.

- John Edward Natrass aged 42 years, stableman.

- Elvet Gwyn Nicholas aged 58 years, repairer.

- Frederick Raymond Ould aged 34 years, repairer.

- David Arthur James Rees aged 23 years, supplies man.

- Denzil Rees aged 63 years, transfer point attendant.

- John Jones Rees aged 50 years, deputy.

- Thomas Llewellyn Rees aged 45 years, repairer.

- William George Rees aged 34 years, ripper.

- Gordon Morlais Rowlands aged 29 years, electrician.

- Edwin Vincent Russ aged 43 years, salvage man.

- Robert Sandow aged 25 years, repairer.

- Bernard Sheen aged 24 years, electrician.

- Joseph Steinmann aged 41 years, contractor’s supervisor.

- Myrddin Stephens aged 40 years, holeborer.

- Leonard Eric Summers aged 26 years, supplies man.

- David John Thomas aged 48 years, shotfirer.

- Donald Thomas aged 29 years, deputy electrical engineer.

- Glyndwr Thomas aged 46 years, lubricator.

- Gwynfor Thomas aged 52 years, stableman.

- Richard David Thomas aged 32 years, face electrician.

- William John Thomas aged 50 years, salvage man.

- William Samuel Thomas aged 62 years, face transfer point attendant.

- Walter Haydn Walters aged 61 years, repairer.

- Raymond Watts aged 46 years, supplies man.

- Kenneth John Wilcox aged 43 years, holeborer.

- Keith Wyn Williams aged 17 years, apprentice electrician.

- Naughton Williams aged 39 years, ripper.

- William Byron Williams aged 36 years, stableman.

- George Hanry Woods aged 27 years, ripper.

The Inquiry into the causes of and the circumstances attending the outburst of coal and firedamp which occurred at the Cynheidre-Pentremawr Colliery, Carmarthenshire on 6th April 1971 by J.S. Marshall, B.Eng (Mining), C. Eng. F.I.M.E., H.M. Divisional Inspector of Mines and Quarries. The proceedings were held on 4th. June when Mr. J.E.G. Roberts, H.M. Coroner for the Three Commons District of Carmarthenshire sat with a jury of eight persons. In accordance of the medical evidence the men died from asphyxia following an outburst of methane gas from the Road 2 Cross-cut Drivage in the Cross Measure 2 Section of Workings in the Big Seam. The report was presented to The Right Honourable John Davies, M.B.E., M.P., Secretary of State for Trade and Industry on the 10th. September 1971.

The first task after the disaster and the bodies had been recovered was to clear the gas out of the mine, This was done and it was found that about 35 yards of the roadway was full of the outburst material. The outburst of coal was so powdery that it was necessary to fill it into sacks to transport it outbye on the conveyor. During the clearing, a stone seven feet by four feet by two feet was found. This had apparently cone from the roof at the face of the heading about 30 yards away. More stones were found as the work went on. Soon after filling was commenced it was noticed that the dust was hot.

When the recovery operations reached the inbye end of the Cross-cut Drivage it exposed a roll in the roof of the seam which rose steeply and flattened out after a vertical displacement of about 12 feet. The last steel arch support erected at the face had been buckled against its neighbour by the force of the outburst. As work went on material continued to slide down from the roof and a cavity 20 feet by 12 feet was formed. This cavity became further enlarged as the disturbed strata in the roof began to peel off. This was altering the character of the site and filling out was suspended on 19th April 1971.

The mouth of a narrow cavity running over the top of the seam could be seen at the to left-hand corner of this large cavity and because this appeared to be a typical outburst feature, further attempts were made to secure the cavity to permit closer inspection. This work proved too hazardous and was finally abandoned on 6th May 1971 and the heading was abandoned and sealed off.

The inquiry came to the conclusion that a spontaneous outburst of coal and firedamp occurred on the geologically disturbed ground at the face of the No.2 Cross-cut Drivage. 400 tons of coal were ejected along with very large volumes of firedamp and went on to recommend that:

- where narrow headings in coal are driven every endeavour should be made to arrange the general layout and coursing of the ventilation so that in the event of an outburst in the heading, the gas would pass directly to the main return.

- advance boring, sampling and determination if the desorption ratio of the coal should be adopted in all coal headings.

- having regard to the fact that, in this case, all six persons died from a shortage of oxygen, careful consideration should be given to the provision of breathing aids to sustain life of persons caught in the gas from an outburst. This might include the use of compressed airlines with frequent breathing points similar to those which are used in the Silkstone Seam at certain mines in Yorkshire. Consideration should be given to the development of specially designed breathing apparatus to be carried by the individual.

- Loudspeaker communications should be installed throughout the workings of each main ventilation section. Any such communications system should have an independent power supply so that it will remain in operation if the colliery mains electricity supply had to be switched off. When satisfactory automatic firedamp alarms are developed they should be coupled to the system.

The Inspector concluded the report by recording that the Joint Advisory Committee on Outbursts of Coal and Firedamp had been enlarged to include additional members with the special scientific and engineering expertise and the inquiry recommended that the Committee should carry out a thorough review of inducer shotfiring techniques for use in both headings and longwall faces and the Code of Precautions should be revised as necessary. All times whilst working, and that it is not placed within two feet of the swing of the pick or other gear with which he may be working.

REFERENCES

The report of the causes and the circumstances attending the outburst coal and firedamp which occurred at the Cynheidre-Pentremawr Colliery, Carmarthenshire, on the 6th April 1971 by J.S. Marshall, B.Eng. (Mining), C. Eng., F.I.M.E., H.M. Divisional Inspector of Mines and Quarries.

Information supplied by Ian Winstanley and the Coal Mining History Resource Centre.

Thanks also to Phil Cullen for providing a missing block of names.

Return to previous page