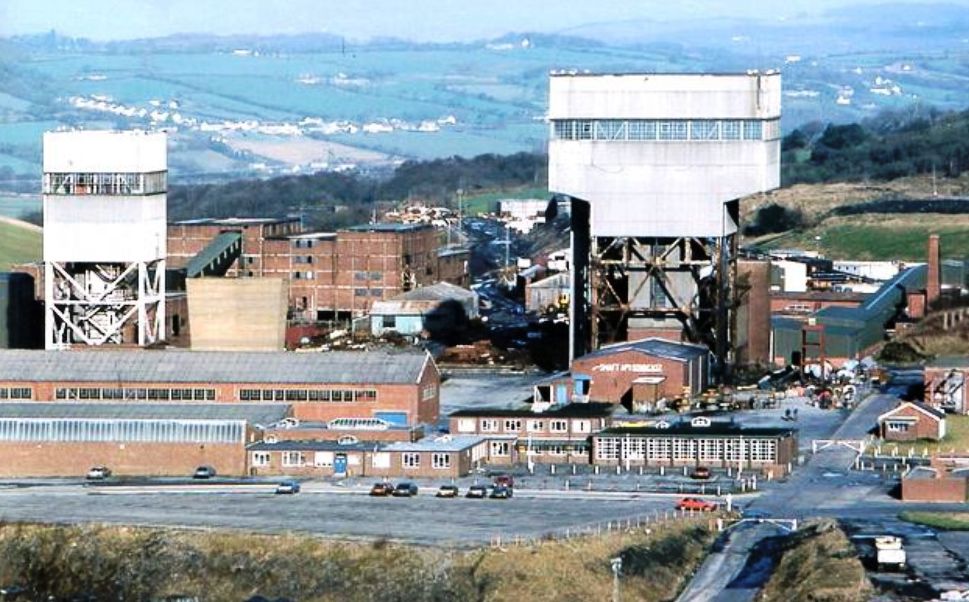

Cynheidre, Gwendraeth Valley (SN 4932 0780 No.1 & 2 Shafts) (SN 5264 1068 No.3 & 4 Shafts)

In 1951 the National Coal Board announced that it had agreed to finance the sinking of a new pit in the Gwendraeth Valley. The new colliery was to be located five miles to the north of Llanelli and was planned to be the largest of its kind in the UK, costing £13.5 million it was panned to work seven seams of prime anthracite coal starting in 1956. All this was based on boreholes proving that the Big Vein was found to be working at a depth of 2,550 men. In their normal optimistic forecasts, the NCB planned output at a million tons per year from 1962 with 3,450 men employed.

The Nos. 1 & 2 shafts were sunk about four miles north of Llanelli and two miles to the south of Pentremawr Colliery between 1954 and 1956 by the National Coal Board to form a new super-pit incorporating (later) Pentremawr and Great Mountain collieries. It was to exploit 13.5 square miles of virgin, deep-lying prime anthracite seams and it was estimated that there were 112 million tonnes of coal in that area. A site was also made for a central coal preparation plant (washery) which came into action on the 23rd of February 1960. The manager at that time was A. Jarvis.

At 3.45pm on the 9th December 1955 while sinking the No.1 Pit two men were killed when they fell down the shaft.

The No.1 Pit was located 450 yards east-north-east of Cynheidre crossroads, the No.2 Pit was located 400 yards north-east of Cynheidre crossroads and approximately four miles to the north of Llanelly. The No.1 Pit (downcast) was 24 feet in diameter and sunk to a depth of 798 yards between March 1954 and August 1956 the No.2 Pit (upcast) was 20 feet in diameter and sunk to a depth of 786 yards between April 1954 and September 1956. They both had tower mounted multi rope friction winders, 150 feet high, with the winding engines installed at the top of the Towers. The No.1 shaft had two motors developing 2,700 hp, it could raise/lower 100 men or 18 tonnes of materials per wind. The No.2 shaft had an 850 h.p. motor.

No.3 & 4 Shafts. British Geological Survey P210600

The No.3 Pit was located 2,050 yards east-south-east of Pontyberem railway station while the No.4 Pit was twenty yards from the No.3 Pit. The No.3 Pit was originally the Great Mountain No.3 Pit and was sunk between 1939 and 1941. It was 18 feet in diameter and deepened to 760 yards in 1955. The 73 metre downthrow Lletty Wilws geological fault separated the No.3 Pit from the Nos.1 & 2 Pits. In fact, this area was the most geologically disturbed in the South Wales Coalfield. The No.4 Pit was 18 feet in diameter and completed in 1964 to a depth of 662 yards. The No.3 Pit was the upcast pit and the No.4 Pit was downcast. The Glynhebog Drift was also renamed Cynheidre No.3 Slant. The Nos. 3 & 4 Pits were near the village of Pontyberem and 3.5 miles away from the Nos. 1 & 2 Pits.

It was intended to work this mine on the horizon method with three main horizons (levels) being 100 yards apart and at a depth of 550, 650 & 750 yards in the No.1 Pit. The first output would come from the east of the pit with locomotives pulling a journey of 1.5 tonne mine cars.

The main seam to have been worked at this colliery was the Big Vein which had a maximum thickness of 9 feet. It was around 1,980 feet below the surface of the mine. Also worked was the deeper Pumpquart seam which had an average thickness of 45 inches, the Braslyd, Ddugaled, Felen and Gras seams.

In 1960 the colliery started production employing 650 men and producing 30,757 tons of coal. In July of that year the transfer of men from Carway had begun, starting with 13 men it continued until all 220 men were absorbed into Cynheidre. The washery started production on the 23rd February 1960.

Donald Box, the Conservative MP for Cardiff North was not very happy when the estimated annual production was lowered from one million tons to that of 550,000 tons in 1961. He demanded an enquiry into the ‘blunder’ of opening both Abernant and Cynheidre at great cost. The NCB replied that the pit had only just started and could not be expected to reach full production in two years, the target figure was still 1 million tons per year. The No.3 Pit opened up an area of the Pumpquart seam but after 27 “blowers” of gas and coal in two years it was abandoned.

In 1961 it was in the No.1 Swansea Area’s, No.1 Group, along with Blaenhirwaun, Cross Hands, Great Mountain and Pentremawr collieries. The total manpower for this Group was 2,810 men, while total coal production for that year was 465,801 tons. The Group Manager was G.A. Thomas, and the Area Manager was J.G. Tait.

In 1964 the NUM Lodge Secretary was Gwyn Charles. In 1977 and 1978 it was Tommy Walker and in 1981 it was Howard Jones. The men at this colliery came under criticism from both the NUM and the NCB in 1968 over their high rate of absenteeism, which was called ‘shocking’. A five-week long joint NCB/NUM investigation could find no reason for the levels of absence from work. In August 1973 the absenteeism rate had reached 30% and the NCB warned that the pit may shut if the rate did not improve.

In 1969/72 the manager was C.B. Jenkins and in 1975/80 it was V.K. Jones. By the January of 1970, this colliery was hitting a creditable output per man shift of 38.8 hundredweights and producing 14,300 tons of coal weekly. At that time the colliery produced 472,000 tons of coal, employing 1,430 men. It had already encountered difficult geology which forced the NCB to drop its target annual output from one million tons to 550,000 tons.

In 1969 a growing resurgence of militantism following the mass closures of the late 1950s and 1960s led to unofficial disputes over surface-men wages and pit closures.

A strike in 1972 was the first total strike of all miners since 1926. Miners’ wages had slipped from nearly the top of the industrial wages league to fourteenth place. To redress this slide a resolution was passed in the NUM Conference of July 1971 demanding a weekly wage of £26 for surface workers, £28 for underground workers and £35 for coalface workers. An overtime ban commenced on the 31st of October and in December a ballot voted 145,482 to l0l,9l0 for a strike. 65.5% of the south Wales miners who voted supported the strike call. On the first of January the strike commenced and by February industry had been placed on a three-day week On the 28th of February the miners returned to work victorious.

Again in 1974, the miners found themselves sliding down the wages league. 93.5% of the South Wales miners who voted supported strike action over the claim for a wage of £35 for surface workers, £40 for underground workers and £45 for coalface workers. The trusted procedure of an overtime ban front the 1st of November led to an all-out strike from the 9th of February which lasted for four weeks. Again a state of emergency was called, a three day week implemented, and finally, a General Election was called for the 28th of February. The incoming Labour Government settled with the miners.

In March 1974 Pentremawr Colliery was officially merged with Cynheidre Colliery.

Outbursts of gas and very fine coal which would throw hundreds of tons into the working areas were to plague this colliery up until the last one in June 1985. In 1963 there were 25 outbursts in the Pumpquart Seam. On the 6th of April 1971, one outburst took the lives of six miners. Yet this was not the only danger that the Cynheidre men encountered, on 16th July 1973, water broke into the workings as two men were boring ahead. Ten men manage to escape immediately, one was rescued later and one man died. 1972 was also a costly year for the colliery, on the 24th of February whilst preparing the pit for the return to work after the national miners’ strike over wages, two men died when they fell down the shaft.

In 1975 the NCB published the ‘Plan for Coal’ which gave an optimistic future for the South Wales Coalfield. As for anthracite coals it stated:

It will be necessary to invest considerable capital to maintain supplies to this market. At Cynheidre they reported that A 2,000 yard locomotive roadway is being driven to develop the western area of reserves. This will provide improved manriding, materials transport, and ventilation. Investigations are also in hand to exploit new reserves in the Pumpquart seam and a limited programme of deep boreholes in the south is planned.

In March 1983, the NUM held a national ballot on whether to take strike action over pit closures, 68% of the south Wales membership voted for strike action, but overall in the UK’s pits only 39% voted that way and a national strike was abandoned. This was the vote that was later to cause a lot of confusion and bitterness at the start of the big strike. Following the return to work, on 22nd April 1985, Cynheidre had attained 70% of expected output levels, with adverse conditions still affecting the BV11 and BV23 coalfaces, and after a good start, the Pumpquart failed to improve.

In 1986 British Coal announced that they were prepared to invest £30 million at Cynheidre Colliery and the proposed Carway Fawr Drift, which was started in 1986, but matters didn’t go as planned and in 1987 Cynheidre deep mine lost £4.5 million. The problems persisted into 1988 with an overthrust on BV15’s and weak roof conditions and roadway convergences on the heavy-duty F4 coalface. This bad geology lost the pit 20,000 tons of coal in output in April and May 1988 alone. The break-even figure for the colliery was 5,250 tons of coal a week, and it was agreed that the F4 heavy-duty face, would work on a Saturday morning to take one cut of the face. This was to keep the face moving due to a combination of very adverse geological conditions and unsuitable canopies on the shield supports.

The Carway Drift project closed down along with Cynheidre Colliery in January 1989. The Colliery, at that time, employed 1,043 men, with the NUM secretary being Mr Terry Issac. At the time of closure, there was an estimated 50 miles of underground roadways in use, and 600 horsepower pumps were removing 9.5 to 10 million gallons of excess water a week from the mine. The main markets had been, domestic, power stations and export.

Some Statistics:

- 1958: Manpower: 400.

- 1960: Manpower: 650. Output: 30,757 tons.

- 1962: Manpower: 812.

- 1964: Manpower: 1,310.

- 1965: Manpower: 1,446.

- 1969: Manpower: 1,135.

- 1970: Manpower: 1,015.

- 1972: Manpower: 1,384.

- 1974: Manpower: 1,100, Output: 320,000 tons

- 1978: Manpower: 1,224. Output: 158,000 tons.

- 1979: Manpower: 1,068. Output: 205,000 tons.

- 1980: Manpower: 1,016. Output: 204,906 tons.

- 1985: Manpower: 1,584.

- 1986: Manpower: 1,384.

- 1989: Manpower: 1,043.

This information has been provided by Ray Lawrence (with additions from Phil Cullen), from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page