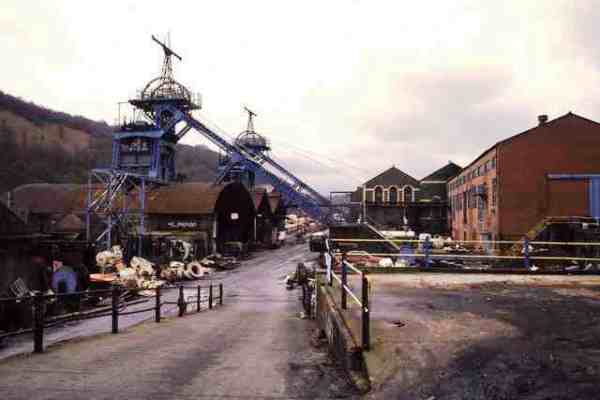

Six Bells Colliery 1989

Copyright © Chris Allen and licensed for reuse under this Creative Commons Licence

Six Bells, Ebbw Fach Valley (national grid reference 219029)

This colliery was located some 12 miles north of the port of Newport and just to the south of the town of Abertillery. Two shafts were sunk; the Nos. 4 & 5. The No.4 shaft was the upcast ventilation shaft and was also used for winding coal, rubbish, materials and men. The No.5 shaft was the downcast ventilation shaft and was also used for full winding duties. The carriages in both shafts were single decks capable of holding two trams per wind, giving a maximum winding capacity of 1,000 tons of coal per pit per shift. The sinking of the shafts commenced in 1890 and was completed in 1892. Both shafts were sunk to the Five-Feet/Gellideg (Old Coal) seam with the No.4 being 18 feet in diameter and the No.5 being 20 feet in diameter. Both were sunk to a depth of 352 yards. The No.4 Pit wound coal from the Three-Quarter seam level at 272 yards.

On the 9th of February 1895, William Matthews aged 36 years, Thomas Day aged 42, John Lamb aged 37, and William Lusty aged 21 years, all engaged in sinking the pit fell out of the bowk and were killed. On the 11th of April another sinker, Eli Morgan aged 25 years, met a similar fate as did Jacob Herbert aged 40 years, on the 2nd of May 1895.

In its life, this colliery worked the Elled, Big, Three-quarter, Black, Meadow Vein, Garw and Old Coal seams. In all a total thickness of coal of 49 feet was found, 40 feet of this in seams two feet thick or over. It was opened by John Lancaster and Company which was not a member of the Monmouthshire and South Wales Coal Owners Association. In 1896 the manager was J. Jeffreys and 72 men were employed underground and 101 on the surface. Mr. Jeffreys was still there in 1911.

In 1901 HM Inspector gave this colliery a glowing report stating that it alone “had cleanliness and orderliness on the surface, which to my mind indicates a desire to have things done for the welfare of employers and employees.” In 1910 it was working the Big and Black Veins.

In 1915 the Business Statistics Company published a book called The South Wales Coal and Iron Companies which reported that D. Davis and Company:

was formed in 1890 to purchase the Ferndale and Bodringallt Collieries, and in 1894 acquired the Tylorstown Collieries. The properties are known as the Ferndale and comprise nine winding pits, all situated in the Rhondda Valleys. The Company has acquired the entire Share Capital of the Welsh Navigation Steam Coal Co, Ltd (the Proprietors of the Coedely Collieries) for the sum of £314,850 and nine tenths of the share capital of John Lancaster and Co, Ltd, a company owning collieries in Monmouthshire. The annual output of the Welsh Navigation Steam Coal Co, Ltd is about 400,000 tons, and of John Lancaster and Co, Ltd about 1,300,000 tons.

Although the height of the Garw seam may have been around 30 inches, the cramped conditions of the seam coalface are made worse by the equipment needed for modern mining

The book continued to state that the company had assets of £1,110,918 and had made a profit of £2,291,427 between 1889 and 1914. The board of directors at that time were; Frederick Lewis Davis, Chairman, David Hannah, Jules Vasse, Thomas Vivian-Rees, Harry Leonard Warner and John Bell White. It later became a subsidiary company of the Ebbw Vale Steel, Iron and Coal Company Limited which sold its mining interests to Partridge, Jones and John Paton and Company in 1935. In 1934 John Lancaster and Company Limited was based at Ebbw Vale with the directors being; Sir John W Beynon, Sir Arthur Lowes Dickinson, David H Allan and Trevor L Mort. The company secretary was Richard Green and the commercial manager was P. Fernihough. This was its only mine. At that time it had its own coal preparation plant. In 1920 Partridge, Jones and John Paton were formed by the Amalgamation of the Crumlin Valley Colliery Company with Partridge, Jones, who then owned Crumlin Navigation, Gwenallt, Blaenserchan and Llanhilleth collieries.

Partridge Jones and Company began trading in 1864 at the Varteg Works with a partnership of Partridge, Bailey, Jones and Messrs Henry. In 1874 they expanded and controlled the Pontnewynydd Iron Works, Golynos Iron Works, Abersychan Iron Works and both Plas-y-Coed and Cwmsychan collieries. In that year a limited company was formed. John Paton by 1895 was one of the principal shareholders in the Pontnewynydd Sheet & Galvanising Works with Partridge, Jones, and with the death of W.B. Partridge in 1909 obtained a seat on the board of Partridge, Jones & Co. In 1920 the interests of both companies were amalgamated.

The coal output from Lancaster Steam Coal Collieries Limited was “Used largely by the principal Railways in Great Britain, Ireland, France, Egypt, Italy, and South America, also by the leading Steamship Companies, and at Foreign Depots for Bunkering purposes.” The shipping ports used were; Newport, Cardiff Bristol, London, Southampton and Birkenhead.

Between 1930 and 1937 this colliery stopped working intermittently due to a lack of trade. When working it worked the Black Vein, Elled, Big Vein, Three-quarter and Meadow Vein seams.

In 1943 it employed 1,334 men working underground and 220 men working at the surface of the mine. The No.4 Pit was working the Big Vein, Elled and Three-quarter seams. The No.5 Pit was working the Meadow Vein and Old Coal seams. 1943/5 the colliery was managed by

W.H. Leigh.

On nationalisation, Six Bells Colliery came under National Coal Board control in 1947 and was placed in the South Western Division’s No.6 Monmouthshire Area. At that time the pits were working the Big Vein (Four-Feet), Three-Quarter (Six-Feet), Meadow Vein (Yard/Seven-Feet), Old Coal (Five-Feet/Gellideg) coal seams plus ironstone. 1,312 men were employed underground and 202 men on the surface of the mine. The manager in 1947 was W.H. Phipps, and in 1954 V. Luther.

In 1950 the NCB estimated that there were 29,226,000 tons of coal reserves left at this colliery. At that time ventilation was by a Walker type fan that produced 200,000 cubic feet per minute. The pit was pumping 50,000 gallons of water up the shafts every day. In 1956 out of a total manpower of 1,430 men, 610 of them were employed at the coalfaces but by 1961 these figures had dropped to 1,214/551 respectively.

The NCB carried out a power-loading survey in 1957 with the coalface at this pit being in the Old Coal seam and 48 inches thick. Its length was 639 feet and coal cutting was by Anderton disc which gave a daily advance of 32 inches which was poor. Coalface manpower was 48 men. In 1957 this colliery employed 87 youths, the joint highest in the Monmouthshire Area.

Vivian Colliery, which was 800 yards to the north, and by then had closed as a production unit, was absorbed into this colliery in July 1958 for the purposes of ventilation (it was a downcast ventilation shaft) and for water pumping. By the 1960s the No.4 pit was winding from the Three-Quarter seam level which was at a depth of 272 yards, and the No.5 pit was winding from the Old Coal seam level. In 1960 the colliery manager was V. Luther, while the under-manager in charge of the No.4 Pit was H. J. Johnson and the under-manager for the No.5 Pit was F. White. During this period the coalface’s were supported by hydraulic adjustable props and metre link bars. The coal was undercut by a compressed air coal cutter with the coalface conveyor also being driven by compressed air. The coal was transported from the coalfaces by electrically driven trunk conveyors and then loaded into trams via a small bunker conveyor.

‘Journeys’ of 25 trams were lowered to the pit bottom by the use of a 250 horse powered main and tail haulage. Supplies were taken into the coalfaces by compressed air haulages. In 1961 this colliery was part of the Crumlin Group of the No.6 Area along with Waunlwyd, Marine and Llanhilleth collieries. Total manpower for the Group was 3,333 while coal production for the year was 824,000 tons. The Group Manager was L. Jarman, with the Area Manager being Lister Walker.

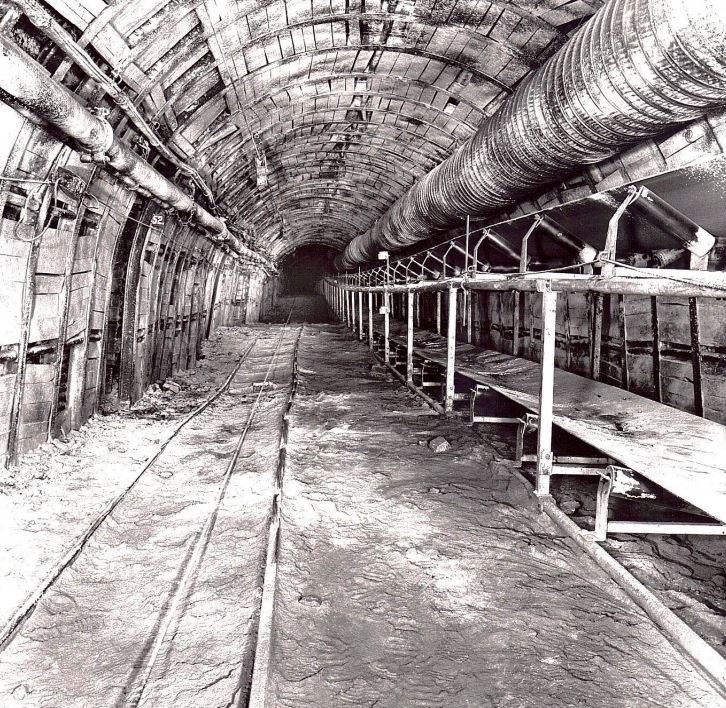

A well supported roadway in Six Bells Colliery with plenty of height. The tramroad on the left was used to take supplies into the development heading while the conveyor belt on the left brought the coal and rubbish out from the face. The large bag in the top right of the picture is for ventilation purposes

As an example of coalface performance in the 1960s, the figures for the M3 coalface for the week ending the 14th of April 1962 give you an idea of manning levels and jobs performed around that time. The standard manning for this coalface was; ten shifts for operating the coal cutter, ten shifts for infusing (water boring) the coal, 130 shifts for advancing the roof supports, 35 shifts for making the machine stables, 15 shifts for advancing the roadways and 15 shifts for packing each end of the coalface. This made a total of 215 man-shifts for the week, at this level of manning the coalface was expected to advance by 155 inches. Due to absenteeism/shortage of men, the actual manning of the coalface was 165 men (77% of normal) while the actual advance attained was 120 inches (78% of normal). This gave the coalface a saleable tonnage of 915 tons at a coalface output per manshift of 99.5 cwts and a production cost per ton of thirteen shillings and eight pence.

In June of 1974, the No.4 Pit was working the T9 and T14 coalfaces, the T9 face which had geological problems was advancing about 6 feet a week, and the T14 about 22 feet a week. In the No.5 Pit, the coalfaces being worked were the Ml and 023, with a weekly advance on both coalfaces averaging 9 feet. The drivage to link up with Marine Colliery was advancing at a rate of 15 feet per week. This pit was also the site of a central workshop.

By the late 1970s this pit was working an area of four square miles with two coalfaces in operation which produced an output per manshift of 3.3 tonnes at the coalface and 0.7 tonnes overall for the colliery. There were seven miles of roadways in use and 2.5 miles of high-speed conveyors to bring the coal out to the pit bottom. It was then transported by rail to the washery at Marine Colliery until around 1977 when the underground link-up was completed. This link saved Six Bells paying about £175,000 per annum in rail costs and also saved 26 surface jobs.

In 1979 the GO1 coalface was the best-performing coalface of between 90 to 119 centimetres thickness in the South Wales Coalfield producing 281 tonnes of coal per day, with the GO2 being the second best coalface producing 237 tonnes a day.

In 1981 the pit was working the Seven-Feet seam from the M2 Coalface at a section of 63” with coal cutting done by ranging drum shearers and roof supports the self-advancing types. It was also working the Garw seam from the G2, G3 and G4 Coalfaces at a section of 32”. Coal cutting was by Gleithobel plough while roof supports were generally posts and bars. The yield of clean coal in respect of total output was 65%. In the Seven-Feet seam, the M2 coalface was 200 metres in length and was expected to advance 1 metre per day on a single coaling shift giving an output of 400 tonnes daily. Its life expectancy in February 1981 was 450 metres. In the Garw seam the G2 coalface was 155 metres long and advancing at a rate of 1.52 metres per day on one coaling shift, output of coal was 245 tonnes daily. This coalface had a life of 570 metres. The G3 coalface was 205 metres long and advanced at the same rate as the G2 but due to it being longer, it produced 275 tonnes of coal daily. It had a life of 1,156 metres. The planned manpower for the colliery at that time was for 138 men at the coalfaces, 68 men on development work, 139 men on other work underground and 80 men on surface work. The manager was J. Waters and he was concerned that manpower wastage would start to affect output and development unless recruitment was permitted.

In 1983 this colliery was losing £10 on every tonne of coal it produced and employed 487 Men. Following the miners’ strike of 1984/85 the NCB consultative minutes show that this colliery had achieved only 73% of the expected output by the end of April 1985.

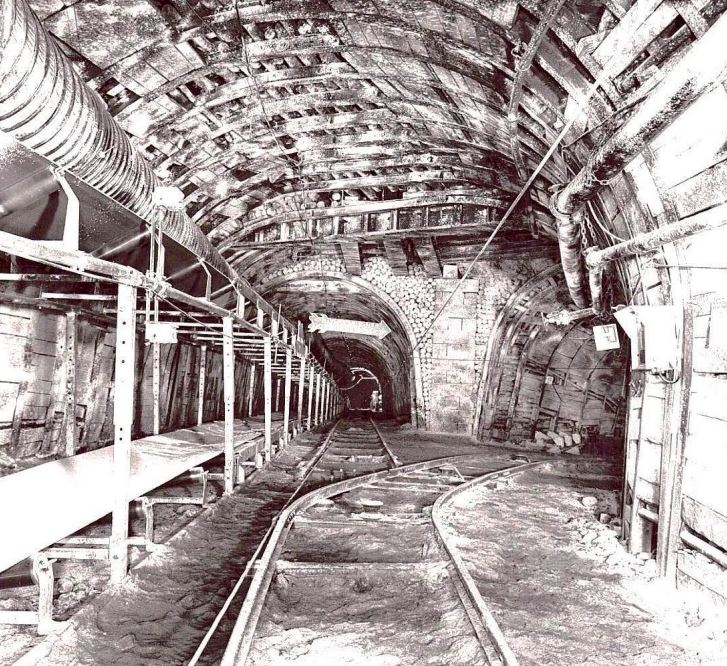

The roadway linking Six Bells and Blaenserchan

Output of coal from this colliery was diverted by underground roadway to Marine Colliery in 1978 with it being closed by British Coal in March 1986.

The No.5 pit mainly worked the Four-Feet, Upper-Six-Feet, Yard/Seven-Feet, Five-Feet/Gellideg, Seven-Feet and Garw seams producing steam, house and gas coals. Based on the Nine-Feet (Black Vein) seam its coals were generally classed as type 301B prime coking coals.

On the 28th of June 1960, a serious accident claimed the lives of 45 miners. A considerable quantity of gas had built up in a roof cavity which was released at the intake road-head face ripping. The cause of ignition was thought to be frictional heat produced by the impact of a piece of quartzitic rock falling for a distance of about six feet, from the roof cavity exposed by shot firing, onto a steel girder forming part of a conveyor canopy. The full report can be found here.

Just some of the others who died at this mine:

- 9/2/1895, William Matthews, 36, William Lusty, 21, Herbert Jacob, 40, Thomas Day, sinkers fell down the shaft.

- 14/4/1895, Eli Morgan aged 35 years, fell down the shaft

- 28/9/1899, Alfred Walden aged 35 years, fall of the roof

- 7/3/1910, Samuel Morgan aged 16 years, fall of the roof

- 12/12/1911, William Morgan aged 54 years, fall of the roof

- 30/1/1912, Benjamin Lucas aged 45 years, fall of the roof

- 3/5/1912, Henry Walters aged 48 years, fall of the roof

- 25/7/1912, Thomas Coombes, aged 40 years, fall of the roof

- 18/9/1912, Gabriel Bryant, aged 48 years, fall of the roof

- 6/1/1913, Job Sayce aged 47 years accident with a horse

- 9/1/1913, Edward Morgan aged 38 years, haulage accident

- 28/3/1913, A.G. Withers aged 17 years, surface washery

- 8/7/1913, William Jones aged 15 years, fall of the roof

- 17/1/1914, John Shelkham aged 47 years, fall of the roof

- 30/3/1914, S.H. Orchard aged 24 years, haulage accident

- 1/5/1914, George Griffiths aged 37 years, haulage accident

- 1/10/1914, Charles Mopp aged 15 years, fall of the roof

- 19/11/1914, James Taylor aged 53 years, surface accident

- 4/8/1928, Richard Jones aged 65 years, haulage accident

- 1/12/1928, Ernest Jones aged 41 years, fall of the roof

Some Statistics:

- 1901: Manpower: 727.

- 1902: Manpower: 777.

- 1903: Manpower: 819.

- 1905: Manpower: 1,149.

- 1907: Manpower: 1,532.

- 1908: Manpower: 1,573.

- 1909: Manpower: 1,909.

- 1910: Manpower: 1,746.

- 1911: Manpower: 1,588.

- 1912: Manpower: 2,171.

- 1913: Manpower:1,884.

- 1915: Manpower:1,884.

- 1916: Manpower: 1,832.

- 1918: Manpower: 2,471.

- 1919: Manpower: 2,177.

- 1920: Manpower: 2,923.

- 1923: Manpower: 2,206. Output: 509,500 tons.

- 1924: Manpower: 2,106.

- 1926: Manpower: 2,200.

- 1927: Manpower: 1,850.

- 1928: Manpower: 2,052.

- 1929: Manpower: 2,000.

- 1930: Manpower: 1,890. Output: 600,000 tons.

- 1932: Manpower: 2,000.

- 1933: Manpower: 151.

- 1934: Manpower: 1,820. Output: 450,000 tons.

- 1937: Manpower: 1,378.

- 1938: Manpower: 1,539.

- 1940: Manpower: 1,540. Output: 600,000 tons.

- 1941: Manpower: 1,540.

- 1942: Manpower: 1,540.

- 1943: Manpower: 1,554.

- 1944: Manpower: 1,640.

- 1945: Manpower: 1,534.

- 1947: Manpower: 1,514.

- 1948: Manpower: 1,541. Output: 387,000 tons.

- 1949: Manpower: 1,414. Output: 342,000 tons.

- 1950: Manpower: 1,541.

- 1953: Manpower: 1,460. Output: 385,000 tons.

- 1954: Output: 286,625 tons.

- 1955: Manpower: 1,395. Output: 291,504 tons.

- 1956: Manpower: 1,430. Output: 319,279 tons.

- 1957: Manpower: 1,357. Output: 342,728 tons.

- 1958: Manpower: 1,657. Output: 456,323 tons.

- 1960: Manpower: 1,291. Output: 338,000 tons.

- 1961: Manpower: 1,214. Output: 402,132 tons.

- 1962: Manpower: 1,230.

- 1974: Manpower: 772.

- 1975: Manpower: 761.

- 1976: Manpower: 844.

- 1978: Manpower: 638. Output: 111,327 tons.

- 1979: Manpower: 503. Output: 115,000 tons.

- 1980: Manpower: 503. Output: 115,008 tons.

- 1981: Manpower: 488.

- 1986: Manpower: 490.

ARAIL (ARAL) COLLIERY

Near Six Bells, Ebbw Fach Valley 218028

This was a small level that worked the Tillerv (Brithdir, Red Ash or Pontygwaith) seam to the west of Abertillery. It was linked to the Gas Works Level.

It was owned in 1870/8 by T. Latch and was managed by M. McArthy. Mr. Latch sold it to J.P. Jones in 1882. In 1888 it was still owned and managed by J.P. Jones, while in 1893 it was sold by the Monmouthshire and Cwm Coal Company to James and Emmanuel. James and Emmanuel terminated their agreement with the railway company on the 2nd of February 1906 which is probably around the time that this level closed as a production unit.

In 1896 it employed 69 men underground and 10 men on the surface with the manager being R. Emmanuel. In 1899 it employed 73 men, in 1900 it employed 83 men, in 1901 it employed 70 men, in 1902 it employed 105 men and in 1910 it employed 27 men. In 1912 it employed 43 men. This figure included the Llandavel Level.

It was also called Aral or Arral (also see the listing on Arral). In 1907 the Aral Farm Level was shown to employ one man, and in 1908 it was producing coal for its owners’ consumption only.

It was listed as closed in 1909.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page