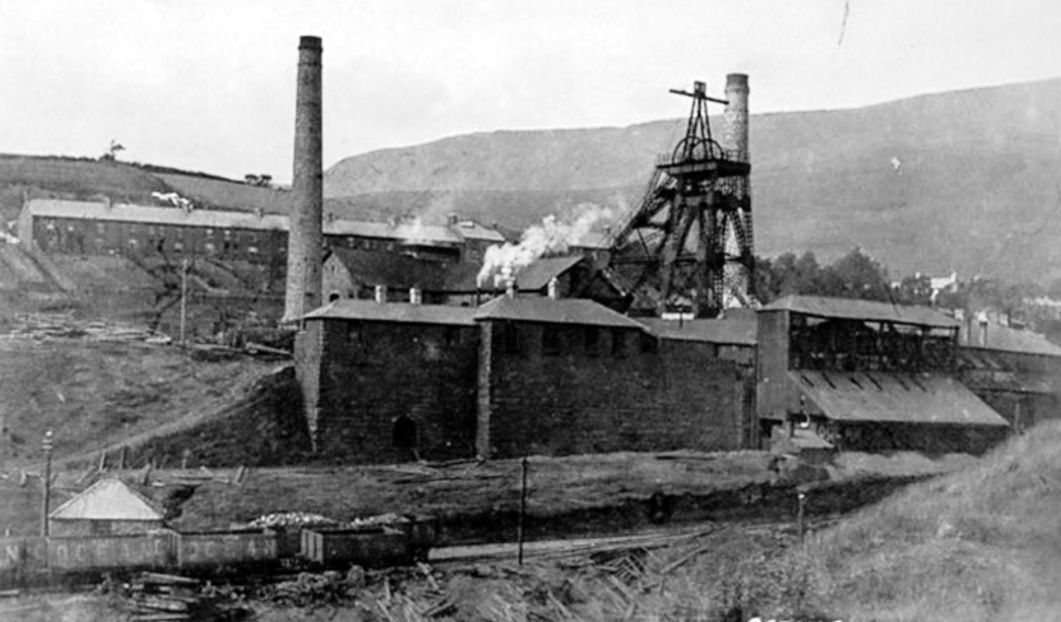

Western Colliery aka Ocean Colliery

Nantymoel, Ogmore Valley (SS 9380 9260)

David Davies (1818-1890) had carried out many non-mining activities successfully before turning to the coal boom in the South Wales Coalfield. Along with his partners, Thomas Webb, Morgan Joseph, John Osborne Riches, Abraham Howell and Ezra Roberts obtained the mineral rights in the Treorchy area and sunk the Maindy and Park Collieries. In 1867, David Davies and Company was formed and went on to sink the Dare Colliery in l870, and the Western Colliery in l873. The manager in 1878 was J. Owen. Eastern Colliery was sunk in 1877, followed by Garw Colliery.

At Western two shafts were sunk about ten miles to the north of Bridgend and 400 yards to the south-east of Nantymoel Church and on the site of the old Blaen-ogwr Colliery. They were fifty yards apart and cost £65,676 to sink. Sinking commenced in 1873 with the first coal being raised in 1876. The downcast was 15 feet in diameter and 318 yards deep. The steam winding engine was built by Messrs. Barker & Cope and had two horizontal cylinders 36 inches in diameter with a six-feet stroke, the drums were 12 feet in diameter for winding from the upper seam and 15 feet in diameter for winding from the lower seam.

The upcast shaft was 14 feet in diameter and 380 yards deep, it was called Edward after the only son of David Davies. They were 50 yards apart. The original mode of ventilation was by a furnace at the bottom of the upcast shaft, it was 9 feet 6 inches long and 9 feet wide and could produce up to 175,000 cubic feet of air per minute. The later steam ventilation fan was of the Schiele type, 15 feet in diameter. In 1945 an electric Waddle type fan, 15 feet in diameter, was installed. The Two-Feet-Nine seam was found at a depth of 257 yards. The Four-Feet seam at 277 yards, the Six-Feet seam at 318 yards, the Red Vein at 320 yards and the Nine-Feet seam at a depth of 349 yards. Some of the seams worked at this colliery were; The Middle Seven-Feet seam at a thickness of 42 inches.

The Yard seam, which was known as the Three-Feet-Ten seam at this pit was worked at a thickness of around 45 inches. The Bute seam was extensively worked at a thickness of up to 66 inches. It was called Brunt’s seam at this pit. The Lower-Nine-Feet seam was called the Bute and was extensively worked it had a thickness of around 71 inches. Also extensively worked were the Caerau, Lower-Six-Feet and Two-Feet-Nine seams. The Caerau seam had a thickness of 54 inches and was worked as the Red Vein. The Lower-Six-Feet seam had a thickness of up to 84 inches. The Two-Feet-Nine seam was up to 60 inches thick.

On the 7th of December 1874, five of the sinkers were killed in a shaft accident, they were; Lewis Davies aged 43 years, Thomas Davies aged 27, Thomas Watkins aged 27, Thomas Morris aged 28 and Rowland Pugh aged 25 years. On the 16th of December 1878 young John Ashton, a hauliers boy was killed by falling under trams – one of the many fatal statistics that blot this and all other collieries of the South Wales Coalfield. He was followed three days later, on the 19th of December, 1878 by Evan Williams a 19 year old collier who died under a roof fall.

In 1887 the Ocean Coal Company was formed, and capital increased from £240,000 to £800,000 in 8,000 shares of £100 each, Davies and his son, Edward, held nearly half of the shares. In 1884/96 the colliery was managed by John Owen. In 1913 Western Colliery employed 852 men. In 1915 the Business Statistics Company, in its book called ‘South Wales Coal and Iron Companies’ reported that the Company was called the Ocean Coal and Wilson’s Limited and that this company “was registered in March 1908, to acquire and hold all or any of the shares of the Ocean Coal Company Ltd, and Wilson, Sons & Co, Ltd, and any Company in which either of such Companies has or have any interest. The Ocean Coal Co, work 9 collieries…the normal annual output of the Collieries is about 2,500,000 tons of coal. Wilson, Sons & Co, has Coal Depots. In addition to their regular business of Coal Merchants and Steamship Agent, the Company owns engineering shops and foundries at Pernambuco, Dakar, Bahia, Rio de Janeiro, and have executed many important engineering contracts.” The book continued to state that the assets of the combined company were £4,886,982 with profits of £301,266 available for distribution. The board of directors was; David Davies, Chairman, A.E. Bowen, William Jenkins, Edward Jones, Thomas Evans, Henry Webb, Alfred Harley, E.E.M. Hett and F.J. Yarrow. This company was a member of the Monmouthshire and South Wales Coal Owners Association.

In early 1921 the Coalfield was still under state control, and due to the 1920 agreement which gave an output bonus of 17.5 pence per shift, wages were running at their highest in the history of the Coalfield. In February of 1921, there was a worldwide trade recession that caused 80,000 miners to be laid off, and to the surprise of everyone, the government announced that it was bringing the date of de-controlling the mines forward to March 1921. The owners were back in control of the collieries again and on the 16th of March gave the men notice that they intended to end all contracts on the 31st of March, on the 1st of April all miners in the United Kingdom (1,100,000) were locked out of their workplaces until they accepted the owners reduced terms. The government declared a state of emergency and troops were moved into the coalfields. On the First of May 1921 the men returned to work defeated, and some would say betrayed by the leadership of the Miners Federation of Great Britain and by October of that year wages in the South Wales Coalfield had dropped to under half of what they were in February. The owners continued to push for more concessions from the miners, not only reducing wages but also extending working hours and abolishing long-established customs and practices.

In 1918/27 the manager was W. D. Williams and in 1930 it was J. Jones.

By 1935 Western Colliery was still managed by Jason Jones and employed 160 men working on the surface of the mine and 770 men working underground, part of the Ocean Empire that employed a total of 7,921 men and produced 2,750,000 tons of coal. On the 3rd of July 1942 the manager of this colliery, J. Jones, was fined £2 plus £3 costs by magistrates for assaulting a surface worker called J. Hughes. Apparently, Mr. Jones objected to Hughes swearing at him. In 1945 it was managed by E.R. Hackford. In 1943 it employed 785 men working underground in the Two-Feet-Nine, Bute, Phils and Three-Feet-Ten seams and 144 men working at the surface of the mine.

On Nationalisation of the Nation’s coal mines in January 1947, Western Colliery was placed in the National Coal Board’s, South Western Division’s, No.3 Area, and at that time employed 133 men working on the surface of the mine and 727 men underground working the Two-Feet-Nine, Bute and Three-Feet-Ten seams. The manager was E.R. Hackford. The manager was still Mr. Hackford in 1954, and in 1955 out of the total colliery manpower of 783 men, 386 of them worked at the coalfaces. In 1954/55 this was one of 42 collieries that caused concern to both the NUM and NCB over the high level of accidents.

In 1956 the price-lists for the payment of colliers were reviewed and in the five feet thick Two-Feet-Nine seam the payment was three shillings and fourpence per square yard for hand filled coal and three shillings and two pence per square yard for machine cut coal. In the six feet, thick Phils seam the payment was three shillings and ten pence per square yard for hand filled coal and three shillings and eightpence for machine cut coal.

Western Colliery was merged with the nearby Wyndham Colliery in 1965 and in 1971 this combine produced 474,874 tons of coal, the highest output for any colliery in the South Wales Coalfield.

In 1981 Wyndham/Western Colliery worked the Five-Feet seam at a thickness of between 1.45 metres and 1.52 metres. The coalface length varied from between 134 metres to 200 metres. The Lower-Six-Feet seam was being worked at a thickness of 1.5 metres and a coalface length of 200 metres. All coal cutting was done by ranging drum shearers, and coalface roof supports were the self-advancing types. Output per man shift on the coalface was budgeted at 4.91 tonnes, and overall for the colliery, it was expected to be 1.51 tonnes. Manpower distribution was; developing new coalfaces, 108 men. Working on current coalfaces, 174 men, other work underground, 204 men, working at the surface of the mine, 110 men Generally this colliery’s coals were classed as type 301A Prime Coking Coals for use as foundry and blast furnace coke. Wyndham/Western Colliery was closed by the National Coal Board on the 7th of January 1984.

Some of the early fatalities at this mine:

- 15/7/1893, Alfred Thomas, aged 28, collier, roof fall.

- 22/5/1925, Robert Davies, aged 57, master haulier, crushed by trams. 24/6/1925, James Edwards, aged 49, collier, roof fall.

- 5/8/1927, Sidney Harris, aged 35, labourer, fell down the shaft.

- 21/8/1928, H.J. Goodwin, aged 32, collier, roof fall.

- 20/1/1929, William J. Rogers, aged 47, timberman, roof fall.

- 4/5/1929, Richard West, aged 51, timberman, run over by trams.

Some statistics:

- 1889: Output: 251,542 tons.

- 1894: Output: 289,604 tons.

- 1897: Manpower: 908.

- 1899: Manpower: 806.

- 1900: Manpower: 788.

- 1901: Manpower: 835.

- 1902: Manpower: 859.

- 1905: Manpower: 850.

- 1907: Manpower: 823.

- 1909: Manpower: 813.

- 1910: Manpower: 842.

- 1911: Manpower: 832.

- 1912: Manpower: 826.

- 1913: Manpower: 852.

- 1916: Manpower: 826.

- 1918: Manpower: 760.

- 1923: Manpower: 986.

- 1924: Manpower: 990.

- 1925: Manpower: 786.

- 1926: Manpower: 1,000.

- 1927: Manpower: 1,000.

- 1928: Manpower: 1,120.

- 1929: Manpower: 1,120.

- 1930: Manpower: 1,080.

- 1933: Manpower: 710.

- 1935: Manpower: 930.

- 1937: Manpower: 892.

- 1938: Manpower: 892.

- 1940: Manpower: 880.

- 1941: Manpower: 950.

- 1942: Manpower: 870.

- 1944: Manpower: 900.

- 1945: Manpower: 929.

- 1947: Manpower: 860.

- 1948: Manpower: 850. Output: 210,000 tons.

- 1949: Manpower: 800. Output: 232,000 tons.

- 1950: Manpower: 885.

- 1953: Manpower: 833. Output: 257,000 tons.

- 1954: Manpower: 831. Output: 249,000 tons.

- 1955: Manpower: 783. Output: 206,508 tons.

- 1956: Manpower: 769. Output: 215,492 tons.

- 1957: Manpower: 774. Output: 225,926 tons.

- 1958: Manpower: 744. Output: 217,768 tons.

- 1960: Manpower: 697. Output: 198,102 tons.

- 1961: Manpower: 638. Output: 179,765 tons.

- 1964: Manpower: 717.

- 1971: Manpower: 1,188. Output: 474,874 tons.

- 1981: Manpower: 670.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page