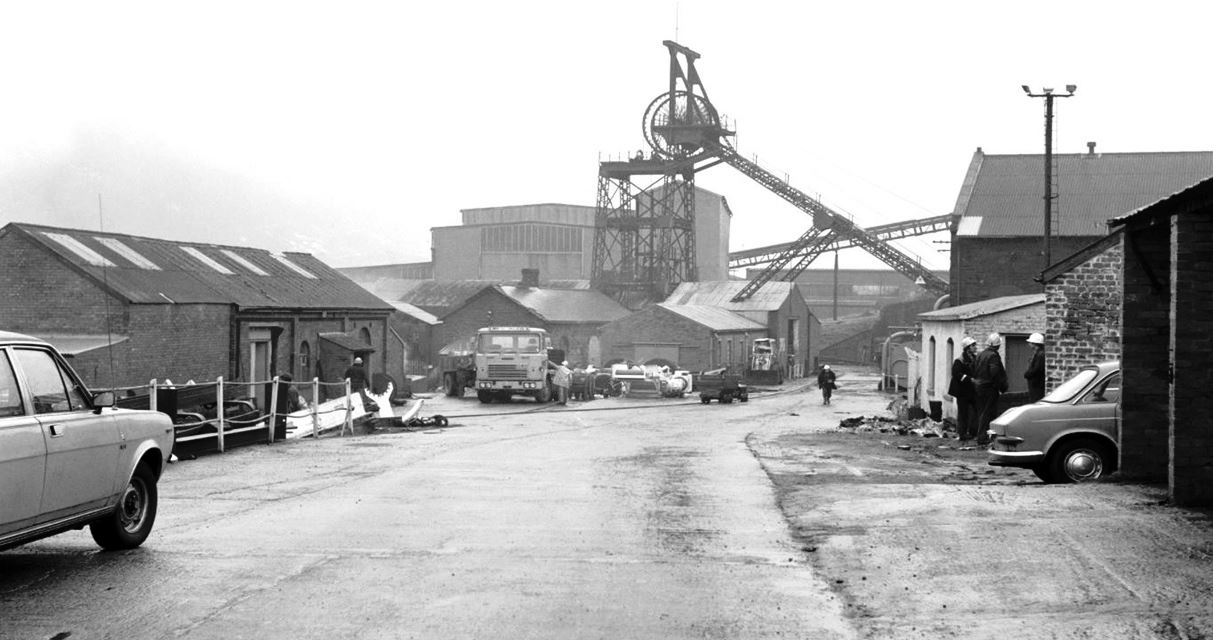

Abertillery 205058

The late 1950s was a time of re-organisation within the National Coal Board in South Wales, economic realities had caught up with the mining industry and in the Monmouthshire section of the Coalfield two major programmes were embarked upon; one concerned the Glyn Valley and the Hafodyrynys New Mine project, the other was a few miles up the road at Abertillery.

The Roseheyworth Colliery and the Cwmtillery Colliery were 2.5 miles apart by surface road but only 1,200 yards by underground roadway. They were merged and a new surface layout and washery were installed at Roseheyworth, a new drift was made to bring the output of both collieries to the surface at Roseheyworth. This drift was opened 100 yards to the north of the Roseheyworth downcast shaft and was driven on 14 feet arches, it was 1,070 yards long with a dip of 1 in 5 and designed to intersect all the workable coal seams down to the Garw seam. The drift was then continued for 670 yards at 1 in 22 into the Garw seam workings at Cwmtillery. This drift also acted as an additional ventilation intake and the shafts at South Griffin, which up to then aided the ventilation of Roseheyworth were abandoned. The collieries involved in the project (Roseheyworth and Cwmtillery) were renamed Abertillery New Mine.

The scheme cost around £3 million and brought about strange arrangements, in 1979 the LB7 coalface in the Roseheyworth section of the mine was manned on one shift by Roseheyworth men and on the other shift by Cwmtillery men who travelled through different shafts. In January 1967 the NCB expended £150,000 on a remote push-button control and TV scanners system to monitor the three miles of underground conveyors. This reduced the need for conveyor attendants by 44 men.

In 1969 A.E. Handley was the manager and the New Mine employed 1,162 men working underground in the Three-quarter, Big Vein, Meadow Vein and Garw seams with 194 men working at the surface of the mine. It was producing 15,000 tons of coal per week from eleven longwall coalfaces in three different seams eight of which were in the 29-inch thick Garw seam. The normal method of working this seam at that time was to undercut the coal and hand fill onto bottom-loading conveyor belts. They were usually double units of 100 yards on each side of the gate road.

In May 1971 a trial was carried out by installing Gleithobel ploughs and hydraulic roof supports on one of the Garw seam coalfaces. This coalface, the G36, then produced 300 tons of coal a week more than the hand filled ones and it was decided to equip all future faces with this equipment.

There then followed a gradual reduction in manpower from 1,040/191 in 1970 to 881/155 in 1972. Mr. Handley was still the manager in 1972 while in 1975 M.V. Edwards was the manager. Ray Young became the manager in 1976 and around this time the New Mine used 35 miles of underground road with 11 miles of them being equipped with conveyor belts and employed 1,036 men. There were 12 miles of haulage roads using 32 haulages

In February 1981 the New Mine was working the Elled seam through the E4 coalface which was 165 metres in length with a thickness of coal of 0.95m, daily advance was expected to be 1.68 metres on double shift coaling which gave a daily output of 300 tonnes. Coal cutting was done by Gleithobel plough with roof supports being the self-advancing types. This coalface had a life of 400 metres. The Lower-Nine-Feet seam was being worked by the LB9 coalface which was 130 metres long with a coal thickness of 1.25m, daily advance was expected to be 1.6 metres on two coaling shifts per day with the tonnage of coal produced being 330 tonnes.

Coal cutting was done by ranging drum shearers with the roof supports being the self-advancing types. This coalface had a life of 430 metres. In the Garw seam, the G47 was 186 metres long and had a section of coal of 0.7 metres. It was expected to advance 1.75 metres per day on two coaling shifts giving 260 tonnes of coal. Coal cutting was by Gleithobel plough and roof supports were by post and bars. It was expected to work until June 1981 when geology and thinning coal would determine its future. The G50 would replace the G47, this coalface was 200 metres long and 0.71m thick, it was expected to advance at a rate of 1.75 metres giving a daily tonnage of 300. The coalface equipment was the same as for the G47. It had a life of 720 metres. In the 1980/81 financial year, the New Mine lost over £5,500,000 or £31.70 for every tonne of coal produced. Later the output of Blaenserchan Colliery was diverted underground to the New Mine. In 1980 it employed 859 men and produced 203,942 tons of coal.

Due to diminishing reserves, with only the thin Garw seam left, it was decided to reduce the area of underground work and concentrate on the Garw seam in the Roseheyworth section of the mine. The Cwmtillery section of the New Mine was then closed in 1982. As part of the preparation for the struggle ahead, in 1983 the NCB announced that this colliery was losing £25.80 per tonne of coal produced. The colliery manpower at that time was 448.

During the 1984/85 miner’s strike a strike breaker on the Roseheyworth side of the New Mine took out an injunction at the High Court in London against the NUM that they “must not incite, procure, assist, encourage or organise persons to congregate at or near the colliery entrances.”

Following the return to work after the strike, by the 22nd of April 1985, this colliery had reached 80% of expected output, and 4,000 tonnes of its coal per week was going to Llanwern Steelworks. It was to no avail, the Area Executive Council Meeting Minutes of the NUM of the 8 of October 1985 stated that the men had agreed to the closure of the colliery. This colliery was closed on the 9th of October 1985 due to extremely poor results as the NCB claimed.

At a meeting of the South Wales Institute of Engineers on the 24th of October 1984 Mr. V.D. Savage stated that this new mine was an “immediate success with output peaking at 17,000 tonnes saleable per week for manpower of around 1,500 men.” He continued to state that: “For the next 14 years, the good performances of the complex resulted in healthy annual profits, however, with the decreasing reserves of coal … by 1976 output had fallen to less than 7,000 tonnes per week and the manpower of about a thousand was scattered throughout the

overextended mine.”

For further details please see the pages on the separate collieries using the links above.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page