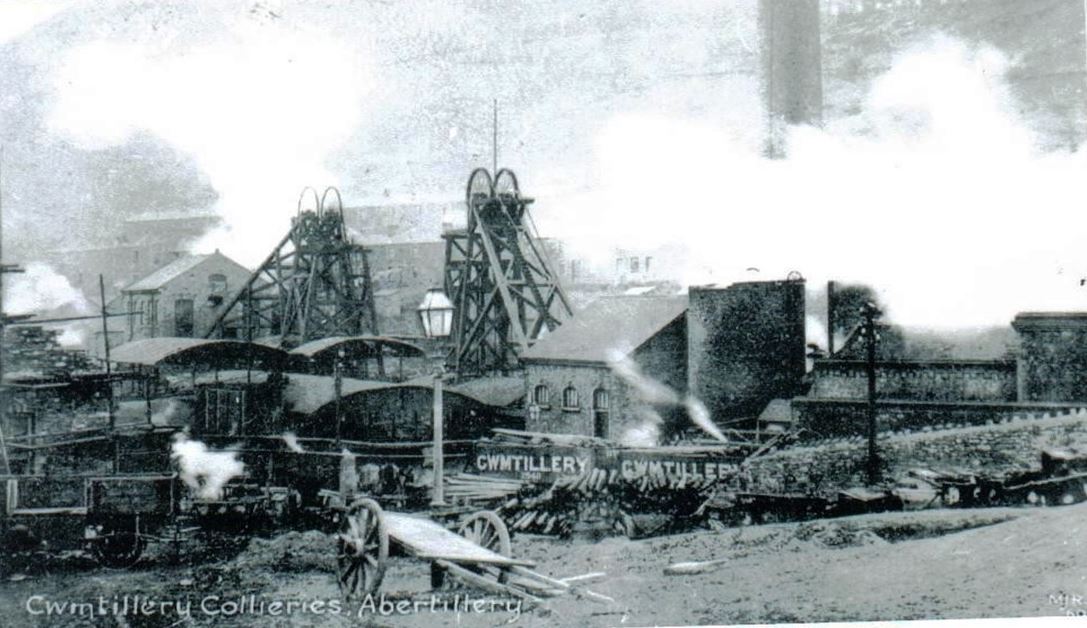

Cwmtillery, Ebbw Fach Valley (218060)

Please also see Abertillery New Mine and Rose Heyworth Colliery

The No.1 Pit was sunk to the Old Coal (Five-Feet/Gellideg) seam which it found at a depth of 261 yards.

The No.1 Pit was sunk to the Old Coal (Five-Feet/Gellideg) seam which it found at a depth of 261 yards.

The No.2 Pit was sunk to the Black Vein (Nine-Feet) seam which it found at a depth of 185 yards.

The No.3 Pit was sunk to the Old Coal seam which it found at a depth of 240 yards. Strangely, the Nos. 2 & 3 pits were sunk before the No.1 pit at this colliery, the dates being 1850 and 1858.

This colliery was opened by Thomas Brown of the Blaina Iron Works in the early 1840s and operated the truck shop system in which the miners were compelled to deal with the company shop. In 1851 it was purchased by John Russell. The South Wales Colliery Company was formed in 1864 which in 1878 employed J. Jones as manager. In 1888 they leased it out to Lancaster, Spier and Company. At that time the No.1 Pit was working the Old Coal seam, and the No.2 Pit was working the Three-Quarter (Upper-Six-Feet) and Big Vein (Four-Feet) seams. The manager was D. Lewis.

In 1891 the lease was altered to Lancaster’s Steam Coal Collieries Limited who bought the Colliery outright in 1916. This company was not a member of the Monmouthshire and South Wales Coal Owners Association. In 1896 (with Roseheyworth) it employed 1,352 men underground and 272 men on the surface working Old Coal, Three-quarter, Big and Elled seams. The manager was still D. Lewis.

In 1911 two production records for the colliery were set; on the 25th of May a high of 2,085 tons for a day was wound up the shafts, while the weekly total for that week was also a record at 11,725 tons. In 1908 and 1913/16 the Cwmtillery Collieries were managed by T.J. Williams and employed 2,986 men in 1913, making it one of the largest collieries in the South Wales Coalfield. The manager in 1918/19/20 was B.P. Thomas. In 1927 the manager of the No.1 was G.H. Simpson and of the No.2 was I. Warfield.

Lancaster’s advertised themselves in 1913 such:

Lancaster’s Steam Coal Collieries Ltd. London, Cardiff and Newport. Proprietors and Shippers of:

Russell’s New Black Vein Steam Coal.

Lancaster’s Navigation Steam Coal. Russell’s Foundry and Furnace Coke.

EIIed House Coal. Washed Nuts, Beans, Peas and Duff. Used largely by the principal Railways in Great Britain, Ireland, France, Egypt, Italy and South America, also by the leading Steamship Companies, and at Foreign Depots for Bunkering purposes.

Shipping Ports: Newport, Cardiff, Bristol, London, Southampton and Birkenhead.

Lancaster’s Company became a subsidiary of the Ebbw Vale Steel, Iron and Coal Company in the early 1920s, and in 1935 it came under the control of Partridge, Jones and John Paton and Company Limited when they purchased the mining interests of the Ebbw Vale Company. In 1934 this subsidiary company was based at the Ebbw Vale’s headquarters at Ebbw Vale and had the same directors, i.e. Sir John W. Beynon, Sir Arthur Lowes Dickinson, David H. Allan and Trevor L. Mort. The company secretary was Richard Green, the commercial manager was P. Fernihough and the sales agents were T. Beynon and Company Limited. At that time it controlled four collieries that employed 2,793 miners who produced 865,000 tons of coal. In 1920 Partridge, Jones and John Paton was formed by the Amalgamation of the Crumlin Valley Colliery Company with Partridge, Jones, who then owned Crumlin Navigation, Gwenallt, Blaenserchan and Llanhilleth collieries. Partridge Jones and Company began trading in 1864 at the Varteg Works with a partnership of Partridge, Bailey, Jones and Messrs Henry. In 1874 they expanded and controlled the Pontnewynydd Iron Works, Golynos Iron Works, Abersychan Iron Works and both Plas-y-Coed and Cwmsychan collieries. In that year a limited company was formed. John Paton by 1895 was one of the principal shareholders in the Pontnewynydd Sheet & Galvanising Works with Partridge, Jones, and with the death of W.B. Partridge in 1909 obtained a seat on the board of Partridge, Jones & Co. In 1920 the interests of both companies were amalgamated.

In 1925 a turbo compressor and condenser plant was installed at the colliery to provide compressed air for the underground haulages, coal cutters and conveyors. It was made by British Brown-Boveri Limited and was capable of providing 12,000 cubic feet per minute.

In 1925 a turbo compressor and condenser plant was installed at the colliery to provide compressed air for the underground haulages, coal cutters and conveyors. It was made by British Brown-Boveri Limited and was capable of providing 12,000 cubic feet per minute.

In 1935, Cwmtillery employed 180 men on the surface and 1,400 men underground producing 400,000 tons of steam coal from the Black, Meadow Vein, and Old Coal seams. The manager around that time was A.E. Hiscox. The colliery possessed a coal preparation plant (washery), coke ovens and a by-product plant. The manager was R. Rutherford.

On the 5th of November 1936, J.W. Elton, the treasurer of the Cwmtillery Permanently Disabled Workmen’s and Widows Fund was gaoled for six months for stealing £35 and £2 from the said fund.

In 1938 J.R. Jones was manager and the No.1 Pit employed 676 men underground and 159 men on the surface while the No.2 Pit employed 509 men underground and 84 men on the surface. The pit head baths were opened on the 25th of November 1939.

In 1943 the manager was R. Watkins and the No.1 Pit employed 592 men working the Old Coal, Yard, Meadow Vein and Three-quarter seams and 137 men at the surface of the mine while the No.2 Pit employed 412 men working the Big and Black Veins and 102 men on the surface of the mine. In 1945 P. Walters was manager.

Cwmtillery was Nationalised in 1947 and was placed in the National Coal Board’s, South Western Division’s, No.6 (Monmouthshire) Area. At that time the No.1 Pit employed 116 men on the surface and 593 men underground working the Yard, Meadow Vein, Three-Quarter, Big and Garw seams, while the No.2 Pit employed 29 men on the surface and 410 men underground working the Big, Black and Meadow Vein seams. The manager at that time was R. Watkins. On the 1st of October 1950, Cwmtillery Colliery celebrated its centenary of producing coal, it was calculated that over 32 million tons had been raised. Considerable underground mechanisation had been carried out since 1947 and by the time of the century celebrations, coal production had gone up from 100,000 tons a year to 290,000 tons a year with the output per manshift increasing in that time from 13 cwts to 21.9 cwts. In 1956 out of a total manpower of 177 men employed underground at Cwmtillery, 60 of them were working at the coalfaces.

In 1957 a Divisional survey of power-loading coalfaces cited one that was working at this colliery in the Three-Quarter seam with a thickness of five feet and a length of 360 feet. Coal cutting was by Anderton disc with the face employing 41 men, daily advance was 53 inches, the second best in the report. In the 1950s and 1960s the managers were; J. Pocock, L. Jarman and A.E. Huxley and in the 1970s to closure they were; H.V. Edwards, R.M. Young and G. Moss.

In 1960 the NCB completely re-organised the surface of Roseheyworth Colliery and linked it with Cwmtillery Colliery to form the Abertillery New Mine. The official date for the merger was the 21st of November 1960. The New Mine employed 714 men at the coalfaces and 1,560 men overall producing 501,860 tons of coal in that year. In 1961 this colliery was still in the No.6 Area’s, Abertillery Group, along with Roseheyworth, Tirpentwys, Glyntillery and Hafodyrynys mines. The total manpower for the Group was 3,147 men, while total coal production for that year was 945,000 tons. The Group Manager was J.A. Moxham and the Area Manager was Lister Walker.

An interesting insight is given into coalface performance at this pit by studying a power loading document giving the performance and payment for team members for the T7 Coalface for the week ending the 18th of August 1962. The manpower on the coalface consisted of a team captain at five shifts for the week. The Disc cutter operators at ten shifts for the week, the Infusers for ten shifts for the week, the Coalface workers at 125 shifts for the week, the stables 30 shifts for the week and roadway workers 35 shifts for the week this made a normal manning of 215 shifts, but in this particular week only 208 shifts or 97% of the standard had been worked. Despite this shortage of manpower the coalface advanced 16.4 feet that week, or 131% of standard advance. This gave a total productivity bonus of £962.70 or £4.63 per man per shift. The coalface had produced 2,070 tons of which 1,653 tons were saleable coal.

In 1977 the longest underground man riding system in the South Wales Coalfield was installed at Cwmtillery Colliery to transport men and materials a distance of 3,000 metres at a cost of £100,000.

In 1981 the NCB intensified the pressure to close this colliery, stating that 5 years ago it had made a profit, 4 years ago it lost £600,000 and in 1980 it had a loss of £4.5 million. The NCB wanted to close the G47 coalface and transfer men to development work in the Roseheyworth side of the mine.

At that time the New Mine was working the Elled seam with a coalface length of 165 metres, and a thickness of 95 cm. The Big Vein with a coalface length of 80 metres and a thickness of 1.7 metres. The Lower- Nine-Feet (Old Coal) seam with a coalface length of 160 metres and a thickness of 1.42 metres. The Garw seam had a coalface length of 200 metres and a thickness of 70 cm. Manpower deployment was; coalfaces 190, development 160, others underground 247, surface workers 135. Expected output per manshift on the coalfaces was 4 tonnes, and overall for the colliery 1.04 tonnes.

Based on the Nine-Feet seam this colliery’s coals were classed as type 301B Prime Coking Coals for use as foundry and blast furnace coke. The Cwmtillery section of the New Mine was closed on the 21st of November 1982 followed by Roseheyworth in 1985.

Some of those who have died in this mine:

- 1/10/1860, John Whitcombe aged 30 years, fall of roof

- 26/1/1863, John Evans aged 30 years, fall of roof,

- 26/1/1863, James Gregory aged 36 years, fall of roof

- 29/7/1868, Richard Jones aged 34 years, roadman, fall of roof.

- 29/7/1868, John Williams aged 21 years, haulier, fall of roof

- 19/6/1871, John Clark aged 50 years, fall of roof

- 4/4/1873, John Corbett, explosion of gas

- 12/6/1874, Frederick Ludlow aged 19 years, fall of roof.

- 30/4/1887, Joshua Jones aged 68 years, haulage accident

- 27/6/1887, George James aged 19 years, fall of roof.

- 6/1/1888, John Court aged 46 years, run over by a truck.

- 17/7/1888, John Evans aged 14 years, fall of roof.

- 8/6/1889, David Lloyd aged 23 years, cage overwound

- 8/6/1889, John Tanner aged 48 years, cage overwound

- 24/9/1889, David Waters aged 55 years, fall of roof

- 5/10/1889, William Hughes aged 44 years, fall of roof

- 12/12/1889, Thomas Saunders aged 27 years, fell down pit

- 10/10/1890, Joseph Holder aged 64 years, fall of roof

- 28/4/1891, Charles Isles aged 25 years, fall of roof

- 22/11/1892, John Evans aged 18 years, fall of roof

- 20/7/1893, Frederick Rabbits aged 21 years, fall of roof

- 25/9/1893, Thomas Harris, aged 40 years, fall of roof

- 8/11/1893, Hugh Roberts aged 26 years fall of roof

- 10/11/1893, Thomas Prosser, aged 68 years, locomotive accident

- 13/1/1894, Thomas Gardner, aged 21, locomotive

- 25/2/1896, Edward Morgan aged 22 years, fall of roof

- 15/5/1896, Charles Ludlow aged 18 years, haulage accident

- 22/5/1896, William Poole aged 20 years, fall of roof

- 1/9/1896, William Lane aged 37 years, fall of roof

- 25/11/1896, George Jones aged 24 years, surface loco.

- 2/9/1897, William Shaw aged 25 years, fall of roof

- 4/8/1899, Edmund Lewis aged 21 years, haulage accident

- 9/8/1899, George Talbot aged 24 years, haulage accident

- 11/5/1910, W. Brown aged 22 years, surface wagons

- 19/1/1911, William Bond aged 23 years, fall of roof

- 23/12/1911, Charles Jones, natural causes

- 5/2/1912, George Bennett aged 24 years, fall of roof

- 6/2/1913, Benjamin Griffiths aged 28 years, fall of roof

Some Statistics:

- 1894: Output: 228,000 tons.

- 1899: Manpower: 1,589 with Roseheyworth.

- 1900: Manpower: 1,820 with Roseheyworth.

- 1901: Manpower: 1,865 with Roseheyworth.

- 1902: Manpower: 1,970 with Roseheyworth.

- 1903: Manpower: 1,917 with Roseheyworth.

- 1905: Manpower: 2,066 with Roseheyworth.

- 1907: Manpower: 2,434 with Roseheyworth.

- 1908: Manpower: 2,464 with Roseheyworth.

- 1909: Manpower: 2,664 with Roseheyworth.

- 1910: Manpower: 2,671 with Roseheyworth.

- 1911: Manpower: 2,727 with Roseheyworth.

- 1912: Manpower: 2,890 with Roseheyworth.

- 1913: Manpower: 2,986 with Roseheyworth.

- 1915: Manpower: 2,986 with Roseheyworth

- 1916: Manpower: 2,986 with Roseheyworth

- 1918: Manpower: 2,760 (with Roseheyworth)

- 1919: Manpower: 2,605.

- 1920: Manpower: 2,605.

- 1923: Manpower: 1,690.

- 1924: Manpower: 2,740.

- 1925: Manpower: 2,700.

- 1926: Manpower: 2,700.

- 1927: Manpower: 2,200.

- 1929: Manpower: 2,200.

- 1930: Manpower: 1,490.

- 1932: Manpower: 2,500 with Roseheyworth.

- 1933: Manpower: 1,441.

- 1934: Manpower: 1,193.

- 1935: Manpower: 1,580. Output: 400,000 tons.

- 1937: Manpower: 1,425.

- 1938: Manpower: 1,428.

- 1940: Manpower: 1,490.

- 1942: Manpower: 1,490.

- 1943: Manpower: 1,243.

- 1945: Manpower: 1,243.

- 1947: Manpower: 1,148.

- 1948: Manpower: 1,304. Output: 264,000 tons.

- 1949: Manpower: 1,119. Output: 276,000 tons.

- 1950: Manpower: 1,148.

- 1953: Manpower: 1,134. Output: 347,000 tons.

- 1954: Output: 316,305 tons.

- 1955: Manpower: 1,108. Output: 321,536 tons.

- 1956: Manpower: 1,121. Output: 329,574 tons.

- 1957: Manpower: 1,138. Output: 344,259 tons.

- 1958: Manpower: 1,161. Output: 313,069 tons.

- 1960 on: Abertillery New Mine.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page